| | Above ground storage tanks | Underground storage tanks

The objectives of fuel storage are to maintain fuel quality and minimize losses in a safe manner. There are several on-farm storage options classified as underground and above ground. Above ground systems include on-ground and/or overhead tanks.

Underground tanks are completely buried with only the pumps, vents and fill connections visible. Vertical, on-ground tanks are usually cylindrical in shape and have their bottoms sitting directly on the ground. These are not as common as a horizontal tank is on the farm. Horizontal, on-ground tanks are cradled close to the ground in a heavy steel frame. An on-ground tank must be equipped with a pump for fuelling vehicles and farm machinery. The last above ground option is overhead tanks. They are supported above the ground on stands and the fuel is gravity fed.

Table 3. Comparison of above ground storage tanks (AST’s) and underground storage tanks (UST’s)

| Tank System | Advantages | Disadvantages |

| ASTs | System can be visually monitored for leaks or corrosion, allowing for an effective response | Increased fire hazard |

| Repairs are quick and less expensive | May require vapour recovery system |

| Minimal excavation required | Increased risk of vandalism or accidental vehicular collision |

| Installation slightly less expensive | Can be aesthetically undesirable |

| Takes up additional space |

| Tanks exposed to adverse weather conditions; additional wear may result |

| Tank exposed to pressure and temperature fluctuations |

| USTs | Do not require any surface space | Repairs are more difficult and expensive |

| Less of an aesthetic concern | Releases and corrosion can go undetected |

| Tank sheltered from adverse weather conditions | Extensive excavation required for installation |

| Reduced fire hazard | Greater corrosion risk for steel tanks and piping |

| May not be required to control the release of volatile organic vapours | Underground piping subject to breakage with freeze and thaw stresses |

Storage Tank Management Systems, Public Works and Government Services Canada, adapted

Above Ground Storage Tanks

Traditionally, many farms used the overhead, gravity fed type systems that would not comply with the AFC. Because of the large expense often associated with new on-ground tank systems (the most recommended), many producers are looking for ways to upgrade their existing systems. This publication will also provide some suggestions and ideas for farmers looking to decrease their risk associated with these tanks. However, if a producer chooses to use their existing tanks with some upgrades, they may still not meet all of the AFC requirements.

Underground Storage Tanks

Under the AFC new underground fuel tanks must be installed by an approved contractor. While farmers are exempt from the AFC, there are compelling reasons why an approved contractor should be hired.

Some protection is provided by the contractor’s insurance if a leak or malfunction can be traced to the installation. If a farmer installs his own tanks, his risk is extended to include both the owner’s and the installer’s liabilities. The Petroleum Tank Management Association of Alberta (PTMAA) has a list of approved contractors. See the For More Information section in the Appendix for contact details.

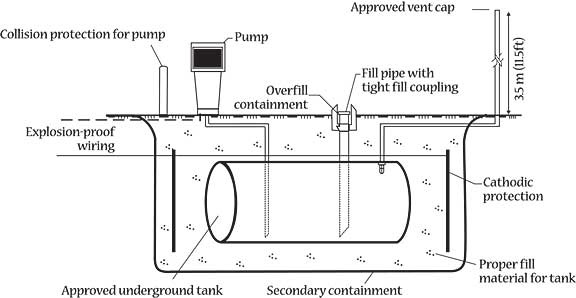

According to the AFC, all new underground construction must include:

- Cathodic protection on steel tanks and piping

- Tank leak detection (monitoring wells or acceptable means of monitoring of secondary containment, ATG, etc.)

- Line leak detection (single, vertical check valve on suction, mechanical or electronic leak detectors on turbine systems, sump monitoring)

- Under-dispenser sumps

- Spill containment on fill pipes (liquid-tight fill buckets)

- Over-fill prevention devices (95% maximum tank capacity)

- Liquid-tight fill couplings (cam-lock connections)

- New, underground Class A4 construction must also include secondary containment on tanks and piping. Class B systems can be installed with single wall tanks and piping

Overview of Regulations, PTMAA

Figure 9: Underground storage tank5

4Class A sites include underground fuel tanks that are within 500 metres (1640 feet) of a water well or 200 metres (650 feet) from a surface water source. All other underground fuel tanks are considered Class B sites.

5This figure is for illustration purposes only. Although most major components are shown, some installations will require additional devices/equipment in order to be in compliance with the Alberta Fire Code.

Source: Agdex 769-1. September 2008. |

|