| | Poor well construction | Old wells | Well pits | Farm water hydrants installed in a well or well pit | Seismic shot holes | Over-application or improper storage of manure or fertilizer | Fuel storage tanks | Pesticide contamination | Contamination during maintenance

Probably the most important asset on your property is your water well. Unfortunately it is often misunderstood and taken for granted. This lack of understanding increases the risk of contamination to the groundwater. Contamination can be a health risk to both people and livestock. Groundwater is an important resource that needs to be protected. Contamination of groundwater is hard to detect in early stages. By the time the problem is obvious, there is little that can be done to remove the contaminant from the system. It can take a very long time for contaminants to be flushed out, often decades or longer. Prevention of pollution is the only effective approach.

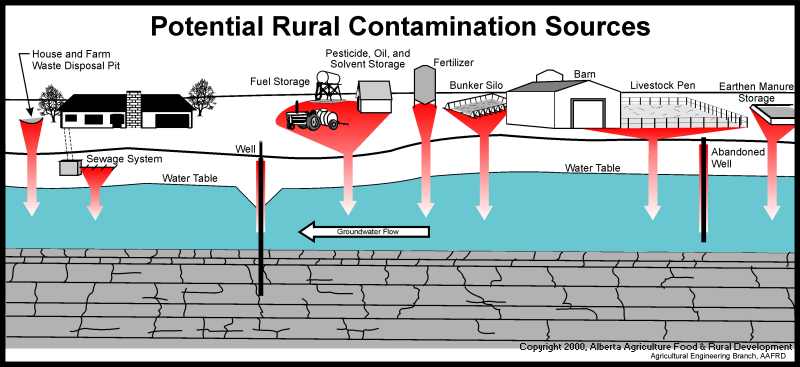

Often the biggest contamination threats are things in your own backyard. The following are examples of potential problems and some ways to prevent them.

Poor Well Construction

- The fastest way to contaminate groundwater is through a well. A well provides a direct path for contamination to travel from the surface to the aquifer.

- An inadequate well casing or annular seal may allow surface water or contaminated groundwater to seep along the outside of the casing and enter your well (see Figure 1, Annulus or Casing Seal).

- Unsecure, missing or inadequate well caps provide a direct path for vermin, insects and other organisms to contaminate the well.

- Locating a well in close proximity to possible sources of contamination could have a negative effect on the water quality

- Multi-aquifer well completion allows mixing of water from several aquifers which may have significantly different water qualities (see Figure 2, Multi-Aquifer Well Completion).The fastest way to contaminate groundwater is through a well. A well provides a direct path for contamination to travel from the surface to the aquifer.

- A proper well casing or formation seal effectively prevents surface water or contaminated groundwater from seeping along the outside of the casing and entering your well (see Figure 1, Annulus or Casing Seal).

- Multi-aquifer well completion allows mixing of water from several aquifers which may have significantly different water qualities (see Figure 2, Multi-Aquifer Well Completion).

| Prevention: The best defense is to hire a licensed water well contractor. They must obtain an approval that authorizes them to drill water wells in the province. To obtain this approval, they must have a certified journeymen water well driller to operate each drilling rig. Standards for drilling, construction and reclamation of wells are outlined in the Water (Ministerial) Regulation of the Water Act. |

|

Figure 2 Multi-Aquifer Well Completion |

Figure 1 Annulus or Casing Seal

Old Wells

- Old unused wells that are poorly constructed or have corroded steel casing can lead to contamination of an aquifer. Nearby wells, completed in that aquifer, may eventually become contaminated.

| Prevention: Old unused wells must be properly plugged. See Module 9 "Plugging Abandoned Wells." |

Well Pits

- Well pits provide a place for contaminated surface water or shallow groundwater to collect. When this water sits in the pit, it can contaminate the aquifer by seeping around the outside of the well casing or flowing into the well. This type of construction also makes it very susceptible to contamination by small animals and insects (see Figure 3, Well Pit). For this reason well pits are no longer allowed.

- Well pits can also be a deadly safety hazard. With changes in atmospheric pressure, air from within the well casing can displace "normal" air in the well pit. Well gases or low oxygen content resulted in human deaths, even recently. People entering the well pit can be asphyxiated. Wells located in basements and pump houses can also be susceptible to this problem.

- Methane gas build-up can cause explosions.

| Prevention: Pitless adaptors provide a safe, sanitary and frost-free connection from the pumping system to the water well (see Figure 4, Pitless Adaptor). For more information, see the publication Pitless Adaptors, listed in Module 12 "Other Resources". |

Figure 3 Well Pit |

Figure 4 Pitless Adaptor |

| Provincial regulation now prohibits the construction of well pits. |

Farm Water Hydrants Installed in a Well or Well Pit

- Hydrants are designed to prevent freezing by draining water back down the well when they are shut off. This means the contents of the stand pipe and hose will syphon back into the well. If the hose is directly connected to the water in a tank, this water will also be syphoned down the well (see Figure 5, Farm Water Hydrant). The contents of stock tanks, sprayers, etc. are examples of possible contaminants.

| Prevention: Always maintain an air gap between the end of a hose and the water surface, or install a backflow prevention device. Always disconnect hoses from the hydrants when not in use. Prevention: Never locate a hydrant in a well casing or well pit. |

Figure 5. Farm Water Hydrant

Poor Sewage Systems

- Shallow groundwater can be contaminated by poorly designed, installed or operating sewage systems (see Figure 6, Poor Sewage Systems). Cesspools constructed over the years have been specifically identified as a greater risk.

| Prevention: The construction of cesspools is no longer permitted. Prevention: In Alberta, only contractors who are certified by the Alberta Onsite Wastewater Management Association, and who hold a valid, annual Private Sewage Disposal System (PSDS) Ticket from the Province of Alberta, are eligible to obtain permits and install private sewage treatment systems. SSee Module 3 "Design and Construction of Water Wells" for minimum distance requirements, and Module 11 "Contacts for More Information," Alberta Onsite Wastewater Management Association, for requirements. |

Figure 6 Poor Sewage Systems

Seismic Shot Holes

- Improperly plugged shot holes can be a direct path for contamination to groundwater. Shot holes are typically 15-18 m (50-60 ft.) deep and are plugged by installing a plastic plug (with identification) into the hole, at a depth of not less than 1 m (3 ft.) below ground level, followed with bentonite pellets and firmly tamped borehole cuttings placed progressively upwards to the ground surface.

| Prevention: Negotiate, beforehand, a more effective method of plugging shot holes with the seismic company by suggesting they install the plastic plug closer to the bottom of each hole and fill from the plug to ground surface with only bentonite pellets. |

Over-Application or Improper Storage of Manure or Fertilizer

- Manure or fertilizer that is applied to land at a greater rate than growing crops can utilize the nutrients can result in nitrates leaching into groundwater. Fertilizer that is applied to lawns or gardens at excessive rates may also contribute.

| Prevention: Balance the nutrient requirements of your crops with the nutrient content of the manure or fertilizer. Conduct regular soil and manure tests and maintain accurate records of application. |

- Storage of manure concentrates nutrients in one location which can increase risk of contamination.

| Prevention: Manure storage facilities should be designed and constructed correctly. See Module 12 "Other Resources". |

Hazardous Material Storage

- There are many other substances and products that need to be properly stored and handled. These could include paint, oil, chemicals, etc.

| Prevention: Hazardous material should never be stored in a building that houses the well and/or pumping equipment. |

Fuel Storage Tanks

- Leaking fuel can contaminate your water supply with hydrocarbons by penetrating water distribution lines or seeping directly into your aquifer.

| Prevention: Design and construct a proper refuelling area. Monitor your fuel tanks for leakage. Practice proper refueling procedures to avoid spills. Be prepared to clean up spills. See Module 12 "Other Resources", Farm Fuel Storage and Handling. |

| Fuel tanks must be located at least 50 m (164 ft.) from water wells. Buried fuel tanks are a major environmental liability and should be avoided. |

Pesticide Contamination

- The most common reason pesticide contamination of wells occurs is poor pesticide handling in the area around the well.

- The highest contamination risk involving field application is when the following factors all come together:

- persistent pesticides

- high water table

- highly permeable soils

- high pesticide application rate.

| Prevention: Never fill sprayer tanks near a well. Always use a nurse tank to haul clean water to the field for pesticide mixing. Store pesticides properly, away from the well. Properly rinse and dispose of empty pesticide containers. |

Contamination During Maintenance

- Wells can easily become contaminated with bacteria when pumps, piping and equipment are laid on the ground prior to placement into the well or during maintenance procedures.

| Prevention: Pumps, piping and equipment should be thoroughly disinfected before going back into the well and the well should be shock chlorinated. |

A better understanding of groundwater and wells is key to preventing contamination problems. Use these preventative techniques to ensure that the wells on your farm provide a safe water supply for years to come.

|

|