| | Causes of well problems | Troubleshooting guide

Water well problems result from many causes including equipment failure, depletion of the aquifer, corrosive qualities of the water and improper well design and construction. Correctly identifying the cause enables you to select appropriate treatment or maintenance to fix the problem rather than abandon the well. This troubleshooting module is designed to help you recognize the symptoms of the problem, identify the cause and select the appropriate course of action. Technical assistance from licensed water well contractors or groundwater consultants may be valuable. See Module 11 "Contacts for More Information".

Causes of Well Problems

There are several basic causes of well problems.

- Improper well design and construction

- Incomplete well development

- Borehole stability problems

- Incrustation build-up

- Biofouling

- Corrosion

- Aquifer problems

- Over-pumping.

The first two causes relate to the expertise and performance of the licensed water well contractor. Borehole stability problems, incrustation, corrosion and aquifer problems are related to characteristics of the aquifer. The last cause, overpumping, is caused by well users.

Exercise

List any problems or symptoms with your well.

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

|

Improper well design and construction

When designing a well, the licensed water well contractor must match the type of well construction with the characteristics of the producing aquifer. Decisions must be made about:

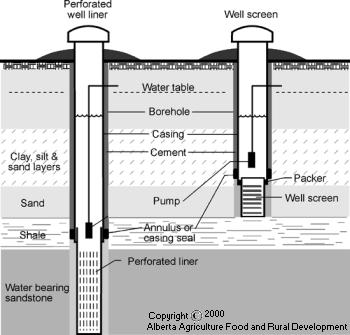

- Perforated well casing/liner vs. well screen (see Figure 1, Perforated Well Liner and Well Screen)

- Slot size of well screen

- Placement of well screen or perforated liner

- Size and amount of sand pack around the well screen (if required)

- Location of the pump in the well.

If poor choices are made, you may experience problems with sediment in your water or reduced well yield. Provincial regulations require that a well must be completed to ensure no damage will be incurred to the pumping system, plumbing or fixtures due to sediment in the water. For more information on well design and construction, see Module 3 "Design and Construction of Water Wells."

Incomplete Well Development

During drilling, mud and bore hole cuttings can partially plug the aquifer. This material must be fully removed by the licensed water well contractor to allow water to freely enter the well. This procedure is part of well development. If the well has not been fully developed, you may experience problems with sediment in your water or low well yield.

Borehole Stability Problems

Borehole stability problems can result from damaged casing and screens, borehole wall collapse, corrosion or excessive water velocities into the well. High water velocity can cause formation particles, like sand, to flow into the well, causing eventual collapse of the borehole wall. It is essential that the proper materials be selected and installed to avoid such problems. A combination of poor materials, improperly placed screens and a poor well seal make it uneconomical to maintain and restore such a well. Often the most cost effective solution is to

drill a new well that is properly designed and constructed.

Figure 1: Perforated Well Liner and Well Screen

Mineral incrustation

Mineral incrustation is a common problem in some shallow water table type aquifers where there is an abundance of dissolved minerals including calcium, magnesium and iron, as well as iron bacteria. When water is pumped from the well, changes in pressure and temperature occur. This creates ideal conditions for minerals to precipitate or settle out, causing scale formation on the casing, liner and screens. A combination of good preventive maintenance and good management practices can minimize the effect of incrustation. Management practices that reduce water pumping rates can reduce the effects of mineral incrustation. A strategy of reduced pumping rate with longer pumping intervals helps prevent incrustation of screens and perforated liners.

| Although incrustation or scale formation occurs mostly in the screen or slotted casing, it can also affect the formation. |

Biofouling

Installing and pumping a well increases the level of oxygen and nutrients in the well and in the surrounding aquifer. Bacteria, such as iron bacteria, may thrive under these conditions. They can form a gel-like slime or biofilm that captures chemicals, minerals and other particles such as sand, clays and silts. Minerals, such as iron, oxidize and get trapped in the biofilm. "Biofouling" occurs where biofilm accumulations are sufficient to reduce water flow. This can mean reduced well yield and water quality.

| Shock chlorination is effective as a regular maintenance technique to kill bacteria and limit its ability to create biofilm. However, shock chlorination is not effective at penetrating biofilm. If biofilm buildup is suspected, the introduction of appropriate chemicals and physical agitation is required to remove the biological plugging material. |

Corrosion

Chemical substances found in water can eat away or corrode metal well casings. To avoid corrosion, the licensed water well contractor must choose a casing material that is suitable for the water supply. For example, licensed water well contractors usually select plastic casing liners and stainless steel well screens for corrosive water. Sulfate-reducing bacteria can also cause corrosion. Shock chlorination can keep these bacteria in check.

Over-pumping

A well is over-pumped if water is withdrawn at a faster rate than the well was designed for or the aquifer is able to produce. Over-pumping is the most common well problem that leads to premature well failure. Over-pumping not only depletes the groundwater aquifer (or source), but it rapidly increases the rate of corrosion, incrustation and biofouling related problems. Over-pumping also increases the rate of sediment particles moving toward the well, causing plugging of the perforated area where water flows into the well. It can also cause the aquifer to settle and compact which further restricts water flow to the well.

| If you are pumping water at a rate close to the well's capacity, excessive pump cycling can increase the problem of biofouling. |

Dissolved Gas in Water

The presence of gas in water wells is common in Alberta. Oxygen, carbon dioxide, nitrogen, methane and hydrogen sulphide may occur naturally in some of the aquifers in which water wells are drilled (e.g. coal seams, fractured shales and sandstones). When gas is present, it is held in groundwater under pressure. Pumping water wells completed in such aquifers can reduce the pressure, releasing the gas. Sometimes gas in groundwater can affect the operation of your well. Even if gas is present, it may still be possible to use your well in a safe manner. Refer to the troubleshooting guide on page 63 for methods of controlling dissolved gas in water.

Aquifer Problems

While most well problems are related to the construction, development or operation of the well, the formation can also be a source of problems. Reduced aquifer yield can be caused by lack of recharge. For example, the amount of water withdrawn can exceed the recharge from rain and snow melt. This is referred to as "mining the aquifer". Sometimes the decline in water level is seasonal. Typically water levels are higher in spring and lower in the fall. Extended dry periods can also impact water levels, especially in shallow water table type aquifers. Checking the water level in your well is an important maintenance procedure. You will be able to identify water level trends and identify well problems or aquifer depletion before the problem becomes serious.

| For more information on checking water levels, see Module 5 "Monitoring and Maintenance of Your Water Well". |

Now go back to the exercise at the start of this module. Try to identify possible causes for each problem you identified.

Troubleshooting Guide

There are four common symptoms associated with most water well problems:

- Reduced well yield

- Sediment in the water

- Change in water quality

- Dissolved gas in the water.

The guide on the next four pages refers to these four symptoms. To use the guide, find the section that identifies the symptom you are experiencing. Look down the left hand column for possible causes of the problem. Beside each cause is listed some indicators you can check for and ways to correct the problem. Be aware that in many cases the well problem can be the result of a combination of causes and therefore correction may be a combination of actions as well.

Symptom # 1 - Reduced Well Yield

| Possible causes: | What to check for: | How to correct: |

| Pump and/or water system | Low pump production in spite of normal water level in well. Leak in system; worn pump impeller. | Have a licensed water well contractor or plumber check the pump and water system. |

Biofilm build-up in well casing, well screen or

pump intake. | Slime build-up on household plumbing fixtures and livestock waterers. Inspect pump and use down-hole camera to check for slime build-up. | Shock chlorinate the well and water system

as required - usually once or twice a year. See

Module 6 "Shock Chlorination". |

| Mineral scale (incrustation) build-up on perforated well casing, well or pump screen. | Scale formation on plumbing fixtures and livestock waterers. Inspect pump. Use down- hole video camera to check for mineral build- up. Calculate the Ryznar Stability Index

to determine the water's incrustinq potential. | Once the type of mineral scale has been identified, the well should be cleaned by a licensed water well treatment specialist. Treatment could include both physical aqitation and chemical/acid treatment. |

| Sediment plugging on outside of perforated casing or screen. | Sediment in water, followed by a sudden decline in yield. | Have a licensed water well contractor redevelop the well. |

| Collapse of well casing or borehole due to age of well. | Sediment in water. Compare current depth of well with original records. A collapsed well will show a shallower depth than the original well. | Recondition the well. If repair is not

economical, plug the well and redrill. •

See Module 9 "Plugging Abandoned Wells”. |

| Neighbouring well interference. | Check for significant drop in water levels in nearby wells. Contact Alberta Environment and Sustainable Development to determine if groundwater use in the area has increased. | Identify other nearby wells located in the same aquifer. Reduce pumping rates as required. |

Aquifer depletion

- rate of withdrawal exceeds rate of recharge

- periods of drought can temporarily deplete

- shallow groundwater zones

| Compare current non-pumping static water level with the level at the time of well construction. A lower level confirms aquifer depletion. Contact Alberta Environment and Sustainable Development to see if water levels are declininq. | Reduce the water use. Install additional storage to meet peak water requirements. Drill a deeper well or one that taps into another aquifer. |

Symptom #2 - Sediment in Water

| Possible causes: | What to check for: | How to correct: |

| Improper well design or construction. | Sediment appears in water shortly after well completion. Well production does not improve with pumping. | Have the licensed water well contractor return to assess and repair the construction problem. |

Insufficient well development after

construction. | Sediment appears shortly after well completion. Well production may improve with pumping. | Have the licensed water well contractor return to redevelop the well. |

| Continuous over-pumping of well. | Sediment appears in water. Compare current discharge rate of well with the recommended rate at the time of construction. | If the current flow rate is higher than the recommended rate, install a flow restrictor on pump. If required, install additional storage to meet peak water requirements. |

| Corrosion of well casing, liner or screen causing holes. | Sudden appearance of sediment in water when there was no previous problem. May be coupled with a change in water quality. Calculate

the Ryznar Stability Index to determine the water's corrosion potential. | Consult a licensed water well contractor. Depending on the well construction, repair or replace well using alternate construction materials. Plug old well. See Module 9 "Plugging Abandoned Wells”. |

| Failure of the annular or casing seal. | Sudden appearance of sediment, coupled with a change in water quality. Test water quality regularly and investigate when quality changes occur | Consult a licensed water well contractor. It may be possible to re-establish the seal. If repair is not economical, plug the well and redrill. See Module 9 "Plugging Abandoned Wells”. |

Symptom #3 - Change in Water Quality

| Possible causes: | What to check for: | How to correct: |

| Corrosion of well casing, liner or screen, causing holes. Holes can allow water of undesirable quality to enter the well. | Change in water quality, may be coupled with sudden appearance of sediment in water. Calculate the Ryznar Stability Index to determine the water's corrosion potential. | Consult a licensed water well contractor. Depending on the well construction, repair or replace well using alternate construction materials. Plug old well. See Module 9 “Plugging Abandoned Wells”. |

| Failure of the annulus or casing seal. | Sudden appearance of sediment, coupled with a change in water quality. Test water quality regularly and investigate when quality changes occur. | Consult a licensed water well contractor. It may be possible to re-establish the seal.

If repair is not economical, plug the well and redrill. See Module 9 "Plugging Abandoned Wells". |

| Iron-related bacteria or sulfate-reducing bacteria (biofouling). | Change in water quality such as colour, odour (e.g., rotten egg) or taste. Check inside of toilet tank for slime build-up and inspect pump. | Shock chlorinate the well. For more information on shock chlorination, see Module 6 "Shock Chlorination". |

| Contamination sources. | Changes in water quality such as colour, odour or taste. Compare results from regular water analyses for changes.* | Identify and remove contamination source. Continue to monitor water quality through regular water testing. |

* In many cases, variations in water quality will not result in observable changes in odour, taste or colour. For instance, in situations where nitrate levels are increasing, there may be no apparent change in the odour, taste or colour of the water.

Symptom #4 Dissolved Gas in the Water

| Possible causes: | What to check for: | How to correct: |

Dissolved gases in well water including:

- carbon dioxide

- methane | Spurting household water taps.

Milky color to the water which lasts only a few seconds.

Cautions:

1. Carbon dioxide is an asphyxiant

2. Methane can be flammable and explosive. | For low concentrations of gas:

• Install an air volume release valve on the pressure tank, if the tank does not have an air bladder. Also ensure the tank is properly vented outside of building.

• Spray water from the well into a sealed

storage tank that is properly vented to the outside.

For higher concentrations of gas:

• Determine the depth that the gas is

• If possible, lower the pump intake to below where the gas is entering. A licensed water well contractor could install a plastic gas sleeve over the pump intake so the gas will be forced out of the water as it enters the intake. The gas will accumulate at the top

of the well, so properly vent the well head so the gas is directed to the outside.

|

| Over-pumping the well. | Malfunctioning pump (gas-locking). Refer to your pump manual to troubleshoot for your pumping system.

Compare the rate at which you are pumping the well with the rate recommended by the driller on the drilling report. | Have a licensed water well contractor or plumber check the pump and pressure system equipment for malfunction. Make sure any new pumping equipment is sized correctly to meet the production capability of the well. Reduce well pumping rate if necessary and install additional storage to meet peak water requirements if required. |

|

|