| | The greenhouse structure | Providing heat | Ventilation and air circulation | Cooling and humidification | Greenhouse floors | Carbon dioxide supplementation | Irrigation and fertilizer feed systems | Computerized environmental control systems

Greenhouse production is a year round proposition. In Alberta this means providing an optimal indoor growing environment when the outside environment can be warmer and drier, or colder than what the crop plants require, and in the case of our winters, can even survive. Periods during the winters can drop to - 30 to - 40 °C, the temperature differential between the greenhouse environment and the outdoors can range from 50 to 60 °C . Conversely, during the summers the outdoor temperatures can rise to +35 °C under the intense Alberta sunlight; this is especially true in southern Alberta . Greenhouse temperatures rise under intense sunlight. This rise in temperature is referred to as "solar gain". To enter the greenhouse, light has to travel through the greenhouse covering, in doing so the light loses some of its energy which is converted to heat. Without a cooling system, the temperature within the greenhouse can rise to over + 45 °C. To successfully optimize the environment within the greenhouse means countering the adverse effects of the external environment as it varies over the normal seasons of the year.

The effectiveness of greenhouses to allow for environmental control is dependent on the component parts. This section describes the component parts of a typical Alberta vegetable production greenhouse, recognizing that specific systems for environmental control can vary and change from one greenhouse to the next as well as over time as new technology is developed and commercialized. There are basic requirements for environmental control that all greenhouses must meet to be able to produce a successful crop. The simplest example is that a structure is required. Beyond this, there are a number of options that can be included. The most precise control of an environment invariably comes with the inclusion of more technology and equipment and the associated higher cost. The driving force for inclusion of newer or more complex systems is the effect on the financial bottom line and the availability of capital.

The Greenhouse Structure

Figure 4. Typical gutter connect, doubly poly, vegetable production greenhouse.

The greenhouse structure represents both the barrier to direct contact to the external environment and the containment of the internal environment to be controlled. The covering material by design allows for maximum light penetration for growing crops. There are a number of commercial greenhouse manufacturers and a number of greenhouse designs that are suitable for greenhouse vegetable crop production. The basic greenhouse design use for pepper production and vegetable production in general is a gutter connect greenhouse.

A gutter connect greenhouse by design allows for relatively easy expansion of the greenhouse when additions are planned. Gutter connect greenhouses are composed of a number of "bays" or compartments running side by side along the length of the greenhouse. Typically these compartments are approximately 37 meters (120 feet) long by 6.5 to 7.5 meters ( 21 to 25 feet) wide. The production area is completely open between the bays inside the greenhouse, the roof of the entire structure consists of a number of arches, with each arch covering one bay, the arches are connected at the gutters where one bay meets the next. The design of a gutter connect greenhouse allows for a single bay greenhouse of 240 m² (2,500 ft.²) to easily expand by the addition of more bays, to cover an area of a hectare (2.5 acres) or more.

With a gutter connect greenhouse, the lowest part of the roof are the gutters, the points where the adjacent arches begin and end. The trend for gutter heights in modern greenhouses is to increase, with greenhouses getting taller. The reason for this is two-fold; firstly, newer vegetable crops like peppers have a requirement for a higher growing environment. Peppers will often reach 3.5 meters (12 feet) in height during the course of the production cycle. Taller greenhouses allow for more options in crop handling and training. Secondly, taller greenhouses allow for a larger air mass to be contained within the structure, and a larger air mass is relatively easier to control with respect to maintaining an optimum environment than a smaller air mass per unit growing area of greenhouse. The reason for this is, the greenhouse environment has inertia (Seginer 1996), once a grower has established an environment in the air mass, it is easier to maintain the environment. Typical gutter heights for modern greenhouse structures are 4 to 4.25 meters (13 to 14 feet), and are quite suitable for greenhouse pepper production. The trend for future gutter height is to increase further, with new construction designs moving to 4.9 to 5.5 meters ( 16 to 18 feet) (Khosla S. 1999).

Figure 5. New greenhouse under construction.

There are a number of options for greenhouse covering materials, glass panels, polycarbonate panels, and polyethylene skins are the prevalent choices in Alberta. Each of the coverings have advantages and disadvantages, the main determining factors usually being the trade-off between cost and length of service. Glass is more expensive, but will generally have a longer service life than either polycarbonate or polyethylene. Typical Alberta vegetable production greenhouses are constructed with double polyethylene skins. Two layers of polyethylene, with pressurized air filling the space between the two layers to provide the rigidity to the covering. The life expectance of a polyethylene greenhouse covering is about 4 years. Energy conservation is also important, the ability of the covering to allow light into the greenhouse and yet reduce the heat loss from the greenhouse to the environment during the winter. New coverings are being developed which selectively exclude certain wavelengths of light and as a result can help in reducing insect and disease problems (pers comm Dr. M. Mirza).

The header house

The header house is an important component of the greenhouse design. The header house serves as a loading dock where produce is shipped and supplies are received. It also serves to house the nerve center of the environmental control system as well as housing boilers and the irrigation and fertilizer tanks. The header house is kept separate from the main greenhouse with access gained through doors.

Lunchroom and washroom facilities are also located in the header house. These facilities should be placed so that they satisfy all food safety requirements with respect to the handling of produce.

The plant nursery

The greenhouse design can also include a plant nursery for those vegetable growers who are interested in starting their own plants from seed. The alternative is to contract another greenhouse to grow and deliver young plants ready to go into the main production area. Pepper plants are transplanted in the main greenhouse at about six weeks of age. Growers starting their plants from seed have to have a nursery area in which to do this. It is important to have a nursery of adequate size to supply enough transplants for the entire area of the production greenhouse. Generally speaking, the nursery area is built to obtain a higher degree of specific control than the main production area of the greenhouse as young plants are more sensitive to the environment. The nursery area can be used for production once the seedlings have been moved out. Heated benches or floors are a must as is supplemental lighting. The requirements for pepper seedling production is discussed in detail in "Pepper plant propagation" section.

Providing Heat

An adequately sized heating system is a must for greenhouse production in Alberta. The output of the system must be able to maintain optimal temperatures on the coldest days of the year. Beyond the actual sizing of the system, and deciding what form of heating to use, ie. forced air, boiler heat, or both there are special considerations in where the heat is applied, specifically heat applied to the air directed at influencing the plant canopy, and heat applied to the floor to influence the root system. The basic premise behind this concept is that it is difficult to provide optimum root zone temperatures during the cold period of the year by only heating the air. Besides the difficulty in driving warm air down to the greenhouse floor, there is also the associated problem of having to provide too much heat to the canopy in order to try to optimize root zone temperatures. Conversely, floor heat, ie. hot water, steam, oil or glycol systems can easily be used to maintain root zone temperatures, they cannot be used to optimize air temperatures without providing excessive root temperatures. It is also important to note that heating systems, in addition to providing the optimum temperatures for crop growth and yield, also can be employed in combination with controlled venting to dehumidify the greenhouse.

Providing heat to the air, the plant canopy

Forced air systems are standard in Alberta greenhouses. Overhead natural gas burning furnaces are normally located at one end of the greenhouse which move the heated air down the length of the greenhouse to the far end. There are a number of types of forced air systems and all try to ensure that the heat is adequately distributed throughout the greenhouse to maintain the environmental air temperature setpoints. Boilers and pipe and fin systems can also be used to provide heat to the air. The main consideration for heating the air is uniform distribution of the heat throughout the entire greenhouse so that the entire plant canopy is equally affected.

Providing heat to the root zone

The most common system to provide heat to the floor or root zone is the "pipe and rail" system. A 5 centimeter (2 inch) diameter steel pipe is placed on the floor between the rows of the crop so that the pipe runs down and returns along the same row approximately 45 centimeters (18 inches) apart. Boilers deliver hot water through this heating pipe. The delivery and return pipe run parallel to one another, forming a "rail" that can be used by carts to run up and down the rows (Figure 4). The carts are useful when working with the plants during pruning and harvest. In this way the heating pipes serve a multiple use.

Providing heat to the "heads" of the plants

The term "plant head" is not likely to found in any botany textbook, it is a term used by greenhouse vegetable growers to refer to the tops of the plant where the growing points are actively developing new shoot, leaves, flowers and young fruit (Portree 1996). Some growers run hot water fin pipe 15 centimeters (6 inches) above the head in order to obtain a more precise control of temperatures. This optimizes pollination of the flowers as well as early stages of fruit and leaf development. This pipe is raised as the crop grows. Currently this system is not commonly employed by Alberta greenhouse vegetable growers.

Figure 6. Pipe and rail floor heat and electric cart.

Ventilation and Air Circulation

Ventilation systems

The ventilation system provides the means by which the greenhouse air is circulated, mixed and exchanged. It allows for a more uniform climate and helps to distribute heat from the heating system (Jackson and Darby 1990) as well as removing heat from the greenhouse when cooling is required. In combination with the heating system, ventilation also provides a means for dehumidifying the greenhouse environment. Ventilation is required throughout the year, however the ventilation required varies with the outside environment. During the winter months ventilation is required primarily for dehumidification, as warm, humid air is exhausted, cool, dry air is brought in. The important consideration when bringing in cold air is proper mixing with the main mass of greenhouse air in order to minimize the negative effects of the cold air contacting the plants. Maximum winter ventilation rates usually do not exceed fifteen air changes per hour (Jackson and Darby 1990).

Figure 7. Ridge vent.

Under Alberta conditions summer ventilation primarily serves to aid in cooling the crop, venting for dehumidification is usually not the goal. In fact, in southern Alberta, maintaining humid air is often the concern. Summer ventilation is triggered primarily by temperature setpoints, and as air is moved through the greenhouse to remove heat, humidity is also lost. So much so, it is difficult to maintain optimum relative humidity levels without also having mist systems or other cooling systems in place. Maximum summer air exchange rates are in the range of 1 complete air exchange per minute.

Ventilation systems can be primarily mechanical; relying on exhaust fans or, natural; relying on the natural upward movement of hot air to exit the greenhouse through ridge or gutter vents. The mechanical or forced air ventilation can be costly, both for the purchase, and for the operation of the equipment (Jackson and Darby 1990). However, forced ventilation is required in order for some evaporative cooling systems to function.

Air circulation, Horizontal Air Flow (HAF) fans

Additional air circulation within the greenhouse can provide for more uniform distribution ofcarbon dioxide, humidity and temperature, especially during the winter (Brugger et al. 1987). Used in combination with the ventilation system, recirculating fan systems ensure the cold air brought in by the ventilation system mixes uniformly with the warm inside air (Jackson and Darby 1990). The fans are relatively inexpensive to operate, and are located to move air along the length of the greenhouse, with the direction of movement alternating between adjacent bays (Blom et al 1991). The fans must be adequately sized to ensure that proper mixing of the air occurs (Jackson and Darby 1990), without the fans being over-sized which can cause excessive air movement reducing yield (Brugger et al. 1987). The general recommendation for sizing is a fan capacity of 0.9 to 1.1 cubic meters per minute per square meter of floor area with a velocity no greater that 1 meter per second across the plants (Brugger et al. 1987, Jackson and Darby 1990).

Cooling and Humidification

During periods of high light intensity, air temperatures rise inside the greenhouse and cooling is required. Increasing ventilation rates serves to bring cooler, outside air into the greenhouse, but during the typical Alberta summer months, ventilation alone is often not enough to maintain optimum greenhouse air temperatures. Alberta growers depend on cooling systems to ensure optimum growing temperatures are maintained. These cooling systems also serve to humidify the greenhouse. Requirements for cooling and humidification vary depending on location within the province. Southern Alberta growers generally contend with harsher summer growing conditions, higher outside temperatures and lower outside relative humidity, than growers in central Alberta. In areas of the province where cooling is required, evaporative cooling systems are being used. Evaporative cooling is most effective in areas where the outside relative humidity is less than 60% (Jackson and Darby 1990).

Pad and fan evaporative cooling

As the name implies, evaporative cooling pads are used in conjunction with mechanical ventilation systems to reduce the temperatures within the greenhouse. The principle of the system is the outside air is cooled by drawing it through continually wetted pads. Pad systems work best in tightly built greenhouses because they require the air entering the greenhouse to first pass through the pad rather than holes or gaps in the walls (Jackson and Darby 1990). If the greenhouse is not tight, the incoming air will bypass the evaporative pads as the pads provide more resistance to air movement. Exhaust fans at the opposite end of the greenhouse provide the necessary energy to draw the outside air through the pads. As the air passes through the pad and is cooled, the air also takes up water vapour and adds humidity to the greenhouse.

Figure 8. Evaporative pad

Mist systems

Both high and low-pressure mist systems are used for cooling and adding humidity to the greenhouse (Jackson and Darby 1990). Mist systems can be employed in both mechanically and naturally ventilated greenhouses. Mist systems work by forcing water through nozzles which break up the water into fine droplets. This process allows the droplets to evaporate fairly quickly into the air. As the evaporation of water requires heat from the environment, the air is cooled. Misting systems must be carefully controlled to provide the required cooling without increasing the relative humidity beyond optimum levels for plant performance, or allowing free water to form on the plants which can encourage the development of disease.

If the quality of the water used for misting is poor, there is the possibility of mineral salts being deposited on the leaves and fruit, which could result in reduced fruit quality and yield loss.

Figure 9. High pressure mist nozzle

Greenhouse Floors

Preparation of the greenhouse floor for greenhouse vegetable production is important to the overall operation of the greenhouse. The floor is contoured so that low spots, which would allow for the pooling of water, are eliminated. Small channels are placed in association with the crop rows with one channel running the length of the single or double row. These channels allow for any drainage from irrigation to the plants to be carried to one end of the greenhouse to the holding tanks for recirculation. These channels are approximately 15 centimeters wide by 15 centimeters deep (6 inches by 6 inches). The depth varies slightly from one end of the channel to the other so the water is intended to drain towards a common end of the greenhouse where another channel carries the water towards a reservoir in the floor located in one corner of the greenhouse.

The floor is covered with white plastic film to seal-off the soil from the greenhouse environment, reducing the problems associated with soil-borne plant diseases and weed problems. The plants are rooted in bags or slabs of growing media placed on top of the plastic floor. The white plastic also serves to reflect any light reaching the floor back up into the plant canopy. Estimations place the amount of light reflected back into the crop by white plastic floors to be about 13% of the light reaching the floor, and can increase crop yield (Wilson et al 1992).

Due to the large area under production, concrete floors are generally too expensive. A concrete walk-way is a practical necessity, usually running the width of the greenhouse along one end wall. This walkway allows for the efficient, high traffic movement of staff within the greenhouse and produce out of the greenhouse.

Carbon Dioxide Supplementation

Carbon dioxide (CO2) plays an important role in increasing crop productivity (Rijkdijk and Houter 1993). An actively photosynthesizing crop will quickly deplete the CO2 from the greenhouse environment (Rijkdijk and Houter 1993). In summer, even with maximum ventilation, CO2 levels within the typical Alberta vegetable production greenhouse typically fall below ambient levels of CO2 [below 350 parts per million (350 ppm)]. It has been estimated that if the amount of CO2 in the atmosphere doubled to 700 ppm, the yield of field crops should increase by 33% (Tremblay and Gosselin 1998). Optimum CO2 targets in the greenhouse atmosphere are generally accepted to be approximately 700 to 800 ppm (Portree 1996).

Carbon dioxide supplementation via combustion

As carbon dioxide is one of the products of combustion, this process can be used to introduce CO2 into the greenhouse. The major concern with using combustion is CO2 is only one of the products of combustion. Other gases which can be produced by the combustion process, are detrimental to crop production (see section 5.5, Air pollution in the greenhouse). The production of pollutant gases from combustion is dependent on the type and quality of the fuel used for combustion and whether complete combustion occurs (faulty burners) (Blom 1998).

Natural gas CO2 generators

One method of CO2 supplementation in Alberta greenhouses is the use natural gas burning CO2 generators placed throughout the greenhouse above the crop canopy. Under lower light, low ventilation conditions, these generators can effectively maintain optimum CO2 levels. However, the experience with these generators during periods of intense summer sunlight, it is that it is still difficult to maintain ambient CO2 levels in the crop. Also, since the combustion process takes place in the greenhouse, the heat of combustion contributes to driving the greenhouse temperatures higher, increasing the need for cooling. Even distribution of the CO2 throughout the crop is also difficult to obtain as the CO2 originates from point sources above the canopy. A fresh air intake should be provided when using these

Figure 10. Natural gas CO2 generators.

Boiler stack recovery systems

Stack recovery systems are receiving more attention by Alberta growers. This system requires a clean burning high output boiler and a system to recover the CO2 from the exhaust stack for distribution to the crop. The CO2 is directed through pipes placed within the rows of the crop, this way the CO2 distribution is improved by introducing the CO2 right to the plant canopy. Carbon monoxide can also be present in the exhaust gas and sensors are used to regulate the delivery of exhaust gas into the greenhouse and ensure that carbon monoxide levels do not rise to unsafe levels.

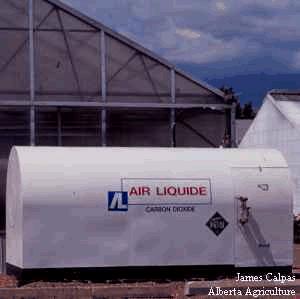

Liquid CO2 supplementation

Liquid CO2 is another alternative for supplementation. The advantage with liquid CO2 is that it is a clean source of CO2 for the greenhouse, as the other byproducts of combustion are not present. For this reason liquid CO2 is especially advantageous for use on sensitive seedling plants early in the crop season (Portree 1996). Distribution to the crop can be accomplished through a system of delivery pipes to the crop canopy as with the stack recovery systems. The draw-back to the use of liquid CO2 has been the cost. It has historically been less expensive to obtain CO2 through the combustion of natural gas than by buying liquid carbon dioxide. Recent work at CDC South in Brooks has developed a cost effective method for liquid CO2 supplementation under Alberta greenhouse growing conditions.

Figure 11. Liquid CO2 tank.

Irrigation and Fertilizer Feed Systems

The fertilizer and irrigation systems provide control on the delivery of water and nutrients to the plants. The two systems complement each other to deliver precise amounts of water and fertilizer to the plants as frequently as required. There are a number of variations on the theme, however the basic requirements are incoming water is injected or amended with precise amounts of fertilizer before it is delivered to the plants. One key point to keep in mind is that every time a plant is watered, it also receives fertilizer. Pumps deliver the fertilizer and water through hoses running the length of each of row. Small diameter tubing, spaghetti tubes, come off the hose with one tube generally feeding one plant. The systems are designed so the amount of fertilizer and water delivered to the plants is equal throughout the greenhouse. Larger greenhouses are often partitioned into a number of zones for watering, with each zone watered sequentially in-turn once a watering event is required, and with the watering modified independently in each zone as required.

Recirculating systems add another level of complexity to the process. In most modern vegetable greenhouses, a certain percentage of the water delivered to the plants on a daily basis is allowed to flow past the root system. The water that flows past the plant roots is referred to as the "leachate". The principles of leaching as well as how to fertilize and water the crop, is explained in more detail in section 5.7.5 Application of fertilizer and water. Recirculating systems are designed to collect the leachate for reuse in the crop. Reusing the leachate minimizes the loss of fertilizer and water from the greenhouse to the environment. Before the leachate can be reused, it must first be treated to kill any disease organisms which may have accumulated in the system. A number of methods for treatment are available and include UV light (Weiler and Sailus 1996), ozone treatment (Weiler and Sailus 1996), heat pasteurization (Portree 1996, Weiler and Sailus 1996) and biofiltration (Ng and van der Gulik 1999).

Computerized Environmental Control Systems

Computerized environmental control systems allow growers the ability to integrate the control of all the systems involved in manipulating the greenhouse environment. The effect is to turn the entire greenhouse and its component systems into a single instrument for control, where optimum environmental parameters are defined, and control is the result of the on-going input of the component systems acting in concert.

Figure 12. Computerized environmental control system

Virtually all computer programs for controlling the greenhouse environment provide for optimal plant growth (Lange and Tantau 1996). There are a wide variety of computerized control systems which are on the market. Generally, the higher the degree of integration of control of the various component systems ie. heating, cooling, ventilation and irrigation systems, the higher the cost of the computer system.

Optimization of the environment for maximum crop production requires timely responses to changes in the environment and the changing requirements of the crop.

The greenhouse environment changes as the crop responds to its environment, and the environment changes in response to the activity of the crop. Fast crop processes, such as photosynthesis are considered to respond instantaneously to the changing environment (Seginer 1996). Due to the dynamics of the greenhouse, the inertia of the environment, it takes longer to implement changes to the environment, upwards of 15 minutes (Seginer 1996). Much of the disturbance to the greenhouse environment is due to the outside environment, the normal cycle of the day - night periods, outside temperatures, the effects of scattered clouds on an otherwise sunny day (Seginer 1996). The environmental control system has to continually work to modify the environment to optimize crop performance in response to on-going change of the dynamic environment.

The ability of a computer system to control the environment is only as good as the information it receives from the environment. The computer's contact with the environment occurs through various sensors recording temperature, relative humidity, light levels and CO2 levels. It is important that quality sensors are used and routinely maintained to ensure that they are operating properly. Sensor placement is also important to ensure accurate readings of the crop environment, for example, a temperature sensor placed in direct sunlight is going to give a different set of readings than a temperature sensor placed within the crop canopy.

Figure 13. Environmental sensor box. |

|