| | About the studies | What did we learn from the snowfluent studies? | How were the studies conducted? | Conclusions and recommendations

Snowfluent is a Canadian technology which atomizes wastewater, and sprays it into the air at cold temperatures. The freezing process separates and destroys contaminants, and reduces odour. It has been used successfully in a variety of situations, including the treatment of municipal sewage and the effluent from a potato processing plant. To test whether Snowfluent had further applications for the treatment of food processing wastes, studies were conducted in 1997 and 1998 on effluents from the Westcan Malting Ltd. plant in Alix, Alberta. The treatment significantly reduced odours and decreased concentrations of most contaminants. The studies showed Snowfluent is an environmentally sustainable winter treatment for food processing effluents high in nutrients and organic material, when applied with wastewater irrigation criteria.

About the Studies

Effluent from food processing plants can cause a variety of problems, because of its high nutrient content, and because anaerobic decomposition of the organic material in the effluent can result in objectionable odours. A new treatment for these wastes, named SnowfluentTM, sprays the wastewater into cold air under high pressure, freezing it into very small ice crystals.

The benefits of freezing contaminated water into tiny droplets have been known for some time. Many dissolved compounds precipitate out of the water and settle. Volatile gases, like ammonia, are released into the atmosphere. Freezing also causes cell-wall rupture of bacteria and other disease-causing organisms, thereby making them harmless.

An economical system for using this technology, called Atomizing Freeze-CrystallizationTM (AFC), was developed about 20 years ago by Delta Engineering Ltd. of Ottawa, Canada, with the cooperation of the Ontario Ministry of the Environment.

Delta now owns worldwide patents on the process and has built a number of permanent Snowfluent plants in Canada and the United States. Though the majority of existing plants are for the treatment of municipal sewage, two are being used for treating food processing wastes.

A fully portable Snowfluent plant is also available for smaller operations, emergency uses, and short-term study projects.

Such a pilot project was undertaken in 1997, with funding provided by Alberta Agriculture, Food and Rural Development (AAFRD) Conservation and Development Branch, the Canada-Alberta Environmentally Sustainable Agriculture Agreement, Delta Engineering Ltd. and Westcan Malting Ltd.

The study's objective was to determine if Snowfluent could be used to meet Westcan Malting Ltd.s need for a treatment system that reduced odours, had no discharge to surface waters, and could recycle the nutrients and water in the effluent for use on 250 acres of irrigated cropland.

A production scale study was conducted in 1998 to test the soil and groundwater impacts of Snowfluent treatment and to confirm the results of the pilot project, with regard to contaminant and odour levels of the treated effluent.

A Possible Solution? Snowfluent technology shows the potential for taking advantage of Alberta's cold winters.

Nutrient and contaminant laden food processing effluent is turned into a plume of clean snow, that can later be applied to crop lands.

What did We Learn from the Snowfluent Studies?

Pilot project - 1997

The malting plant effluent pilot study had four specific questions to answer:

1. What percent of the nutrients are removed by AFC technology?

2. At what point in the process are contaminants reduced?

3. What effect does Snowfluent have on soil and shallow water table?

4. Is there a health risk to operators during the snowmaking process?

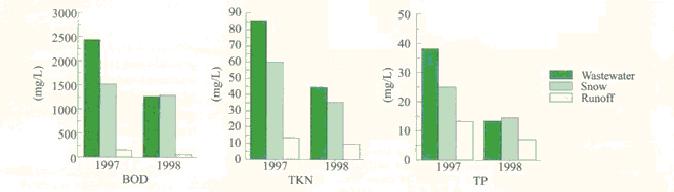

1. Nutrient removal - The pilot study showed Snowfluent significantly improved the quality of the malting wastewater, fresh from the plant. Up to 88% of the total nitrogen was removed by the process, and up to 67% of total phosphorus. Salt concentrations were reduced in most of the meltwater volume. Total dissolved solids (TDS) went from 1630 mg per litre to 470 mg per litre, a four-fold reduction. Faecal coliforms were virtually eliminated.

2. Phase of contaminant reduction - Approximately 38% of the biochemical oxygen demand (BOD) was removed in the atomization/crystallization phase, as was the majority of the microbial content. Water losses during snowmaking concentrated some contaminants. Thus, concentrations appeared slightly higher in the fresh snow than in the wastewater. However, contaminant reductions during the aging of the snowpack resulted in cleaner meltwater.

Chemical constituents and bacteria levels were 60-99% lower in the Snowfluent meltwater than in the untreated effluent. BOD levels were reduced 99%. Surface water quality guidelines were met for all parameters except phosphorus.

3. Effects on soil and groundwater - Soil and groundwater data from the pilot study were limited, due to an absence of background information. However, meltwater from the metre of snowpack generally did not infiltrate below plant root depths.

4. Operator safety - Odours in the snow plume were insignificant compared to typical lagoon odours and were undetectable 30 metres from the plume. Air within the plume and immediately downwind of the snowmaking guns had high levels of bacteria. At 100 metres downwind, bacteri were at background levels. The use of standard protective breathing equipment would eliminate any operator risk. There was no off-site odour or public health risk from the process.

Production scale study - 1998

Though the pilot study showed Snowfluent treatment could significantly reduce odour and improve water quality for food processing effluents, it was unable to determine the effects of Snowfluent on groundwater and soils. A production scale test was conducted in February and March 1998 to better define these parameters. This study was also expected to confirm the results of the pilot test at production scale.

The site represented a worst case scenario because of the highly permeable soils and shallow water table, and because the lagoon wastewater did not meet Alberta's draft wastewater irrigation guidelines for TDS and sodium absorption ratio (SAR). The wastewater was also anaerobic after three months storage under ice.

BOD and contaminant reductions during different phases of the Snowfluent process - 1997 and 1998 tests

In contrast to the pilot test, a narrow but strongly objectionable odour travelled off-site during snowmaking. Follow-up tests suggest that anaerobic storage conditions in the lagoon caused the odour problem.

The results of the pilot study with regard to nutrient and bacteria levels were confirmed in this study. Odours after snowmaking were insignificant. Ammonia concentrations in the lagoon wastewater were 22 mg per litre, four times the level of the fresh wastewater measured at the Westcan Malting Ltd. plant in 1997. The high levels of salts in the wastewater percolated down to the shallow water table immediately after snowmelt, then declined through the summer.

TDS levels in groundwater samples taken after snowmelt and throughout the summer exceeded the 500 mg per litre aesthetic limit of the Canadian Water Quality Guidelines for Drinking Water in 44% of the samples. These exceedences are not a result of the Snowfluent process, but rather a function of the quality of the wastewater being treated. The high levels of TDS in the wastewater, and the highly permeable soils, would cause these exceedences irrespective of whether the land application system used was irrigation or Snowfluent.

A small number of samples exceeded nitrate, nitrite or faecal bacteria levels under the Canadian Drinking Water Guidelines. However, these random detections could not be attributed to the application of Snowfluent and were thought to come from livestock which had access to the study site.

The pilot project showed if snowmaking occurs before ground frost penetrates deeply, the snow pack will act as insulation and inhibit deep frost from forming. The meltwater then infiltrates directly into the soil, without a chance for overland flow to occur. The opportunity for the precipitates in the meltwater to re-dissolve is reduced, lowering the risk of these chemicals being carried past the root zone.

If snowmaking starts after frost has penetrated deeply into the soil, the insulating effect of the snow pile will keep the ground frozen longer. The latter situation was in effect during the 1998 study, and the high level of salts in the groundwater and soil may reflect this.

In the production scale study, more contaminants were retained in the less porous, higher organic content surface layers of the soil profile.

Forage crops are typically grown on Snowfluent sites. On this site, alfalfa showed a favorable response to the snowmelt and caught up quickly where large snow piles had delayed growth. Concentrations of nitrate (NO3) in the surface layer of the soil after snowmelt were within ranges usable by typical pasture grasses. Phosphate (PO4) levels were adequate or greater for annual crop use.

Delta Engineering Ltd.'s fully mobile Snowfluent AFC plant s mounted on a dual tractor-trailer rig, with an integrated power supply.

How were the Studies Conducted?

Background

Westcan Malting Ltd. is the third largest malt producer in Canada, currently processing 95,000 tonnes of barley, and producing 33,000 tonnes of malt, mostly for export. The company is now upgrading the plant, to increase malt output by 25%, thus increasing the amount of effluent produced by a similar amount.

In the existing wastewater system, nutrient-laden effluent is sent through an underground pipe to a small, primary lagoon. It is then discharged to a large storage lagoon. During the growing season, the storage lagoon contents are used to irrigate 250 acres of land adjacent to the plant. During winter, the effluent is stored in the lagoon, which freezes over as temperatures drop. The ice then blocks the circulation of air to the wastewater.

Continuing bacterial digestion and decomposition of the organic matter in the lagoon rapidly uses up the available oxygen and the process becomes anaerobic. This anaerobic decomposition produces gases which cause objectionable odours when the ice melts.

Pilot project 1997

Fresh wastewater was trucked directly from the Westcan Malting Ltd. plant in Alix to two test plots at the Alberta Research Councils facility in Vegreville. The plots, which measured 15 metres square, were positioned so that natural drainage would direct meltwater toward two outlets, equipped with sampling and measuring devices.

A 30 centimetre high earthen berm was built around the perimeter of each plot to contain the snow pile. One plot was fitted with an impermeable geotextile liner to collect all runoff. The other was left unlined and nine nests of groundwater wells were installed in and around the plot. Each nest had three wells, to sample water at depths of 0.8 metres, 1.6 metres and 2.4 metres.

Snowmaking could proceed only at night due to unseasonably warm daytime temperatures. Over five nights, approximately 660 cubic metres of malting effluent were processed, creating a layer of Snowfluent two to three metres high on the two test plots.

During snowmaking, samples were taken of the fresh effluent and the freshly-made Snowfluent. Meltwater and groundwater samples were taken throughout the spring thaw period. Water and snow samples were analyzed for nutrients, organic material, salts, and faecal coliforms. Water volumes of both the snow and the runoff were measured. Samples for airborne bacteria were taken during the snowmaking.

Production scale study - 1998

The study took place on pasture and hay land adjacent to the Village of Alix lagoons. These lagoons are used to store the malting plant wastewater through the winter. The wastewater was anaerobic after three months of storage under ice.

The parcel of land chosen for the tests had a natural drainage that helped contain all the meltwater from the Snowfluent. Normally, the site would have been a poor choice for wastewater irrigation or lagoon storage, as the soils are highly permeable. For the study, however, they were ideal, as they allowed rapid leaching to the 14 nests of test wells. Each nest of wells had three groundwater sampling piezometers, installed at depths of 1.1 metres, 2.4 metres, and 3.6 metres. Three additional shallow test wells were installed downslope of the snowmaking site.

Approximately 23,000 cubic metres of wastewater were processed over 43 days. The warm weather caused the portable Snowfluent plant to operate at about 27% of its rated capacity. Air samples at the snow piles and lagoons were taken after snowmaking.

Conclusions and Recommendations

Snowfluent is a safe and environmentally sustainable winter treatment method for high nutrient and high organic content wastewater. Avoiding extended storage in lagoons and processing the wastewater quickly, will limit anaerobic decomposition and reduce associated odours during snowmaking.

A quantitative analysis of atmospheric inputs and odours would be valuable. Risks to soils and groundwater are related to the characteristics of the raw wastewater and the application site, not Snowfluent application. Thus the wastewater must meet Alberta Environmental Protections 1997 Draft Guidelines for Municipal Wastewater Irrigation for TDS and SAR. Soils at the application site must conform to these guidelines.

Snowfluent is also an effective method for pre-treatment of food processing wastewater, to reduce salinity and excessive nutrient concentrations. Such pre-treatment makes the wastewater suitable for conventional treatments. The use of Snowfluent for wastewater pre-treatment should be on a contained, lined pad, with runoff directed toward holding lagoons for additional treatment or land application. Alfalfa is a viable forage to grow on Snowfluent land application sites.

This fact sheet is one of a series of special research bulletins on agriculture and resource management produced by Alberta Agriculture, Food and Rural Development.

Find more information on this subject contact AARD, Irrigation and Farm Water Division:

James Wuite at (780) 427-3747 or

call the toll free Alberta Government RiteLine: 310-0000

The cooperation and assistance of Glen McRuer, Byron Mickelson and Paul Mehle of Westcan Malting Ltd., and of the Village of Alix are gratefully acknowledged.

|

SnowfluentTM and Atomizing Freeze - CrystallizationTM are registered trademarks of Northern Watertek Corporation. |

|