| | Surface water management | Subsurface water management | Relief wells

A saline seep forms when groundwater flows from a recharge area to a discharge area. The groundwater dissolves soluble salts and carries them as it flows through the bedrock and subsoil. When the salty groundwater rises to the soil surface in the discharge area, the water evaporates, leaving the salts behind. (See Dryland Saline Seeps: Types and Causes, Agdex 518-12, for more information on saline seep formation.)

Dryland saline seeps can be controlled using structural or biological controls. Biological controls are discussed in other factsheets in this series. Generally, structural controls lower water tables and improve accessibility in discharge areas faster than biological controls. However, structural controls are usually more expensive than biological controls and are not always totally effective. Even more importantly, they usually require a licence from Alberta Environmental Protection because of their potential environmental impact.

Structural controls for discharge areas include surface water management, subsurface water management and relief wells. Structural controls for recharge areas usually involve only surface water drainage.

Surface Water Management

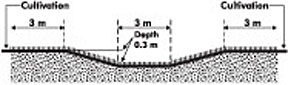

Grassed waterways can be used to drain excess water ponded in discharge or recharge areas. Their main advantage is the erosion protection provided to the drainage channel by the grass cover and low channel slope. Grassed waterways are typically flat-bottomed with a standard bottom width of 3 m (Figure 1), which allows construction with a grader or scraper. The side slopes are less than 25 per cent (1 m vertical to 4 m horizontal), so the waterways can be easily crossed by farm equipment. The best forage mix for a grassed waterway depends on the nature of the area being seeded. Refer to Watercourse Improvement and Gully Restoration (Agdex 573-5) and Grassed Waterway Construction (Agdex 573-6) for more information on construction, forage mixes and maintenance.

Figure 1. Cross-section of a typical grassed waterway

Subsurface Water Management

Subsurface (tile) drainage involves the installation of perforated, corrugated plastic tubing. Subsurface drainage is not commonly used to control dryland salinity because it is expensive, not suited to all salinity types and requires engineering design. However, it will satisfactorily lower water tables in dryland seeps if the conditions are right and the system is properly designed, installed and managed.

The purpose of subsurface drainage is to remove water and desalinize the root zone through leaching. Initially, subsurface drainage removes groundwater near the drainage tile. Over time, precipitation leaches salts from the root zone, and the subsurface drainage removes the leachate, so the salty water cannot rise back up to the soil surface.

Subsurface drainage is more effective when above-average precipitation increases leaching. Leaching of salts can be enhanced with low-moisture-use crops, summerfallow and snow trapping on the drained area.

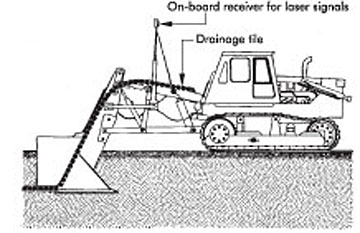

Subsurface tubing can be installed with various types of machinery. The trenchless plow (Figure 2) is the most commonly used. It installs the tubing in a single operation. Automatic laser grade-control equipment may be used to keep the tubing at the correct grade. Bucket-wheel and bucket-ladder trencher machines are also available. These types of machines usually excavate the trench and lay the tubing in one operation; backfilling of the trench is a separate operation. If the seep is extremely wet, a backhoe or even a dragline may be needed. A backhoe and hand laying can be used for small projects, particularly in stony areas, as long as the tubing is at the correct grade.

Figure 2. Trenchless plow with automatic grade-control system

Before construction begins, a detailed engineering plan and cost estimate should be completed for the drainage system. Alberta Agriculture irrigation specialists provide engineering design services for subsurface drainage systems on irrigated land on a fee-for-service basis.

In particular, an engineering plan is needed to identify a suitable outlet for the drained water. Depression bottom and slough ring salinity types occur in low areas of the landscape, making it difficult to locate an outlet lower than the seep. Subsurface drainage could be used for controlling some outcrop saline seeps because outlets can be easier to locate and because biological controls are not always effective for controlling outcrop salinity. (For more information on salinity types, see Dryland Saline Seeps: Types and Causes, Agdex 518-12, or contact an Alberta Agriculture salinity specialist.)

Relief Wells

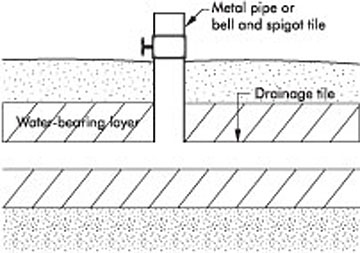

Relief wells are costly and require engineering design, but they can effectively control springs and soapholes associated with artesian salinity under certain conditions. The wells should be completed in the pressurized water-bearing layer (Figure 3). In Alberta, these layers may consist of coal, gravel, sand or fractured bedrock.

Proper installation requires very detailed soil and groundwater investigations. The relief well may flow free, be pumped or be connected to a buried drain.

Figure 3. Relief well

Relief wells can be more effective than subsurface drainage in controlling high water tables. If the quality of the drained water is good, the water could be used for domestic or livestock purposes.

For more information on salinity control, contact the Alberta Agriculture and Food Ag-Info Centre at 310-FARM (3276), or refer to the factsheet Dryland Saline Seeps: Types and Causes, Agdex 518-12.

Prepared by

Donald Wentz, formerly with Alberta Agriculture and Food.

Source: Agdex 518-16. Revised July 1998. |

|