| | Seeding | First Transplanting | Plant Density | Setting up the Greenhouse | Hanging Trough System | Transplanting | Plant Balance | Pruning and Plant Training | Twinning to Increase Crop Density | Flowering | Pollination | Fruit Set Development | Harvest

Seeding

The propagation area or seedling nursery area must be cleaned and disinfested prior to use. Fresh seed is also important as seed older than one year can have reduced germination rate and vigour.

The crop is seeded approximately November 15. Seed is placed directly into rockwool plugs that have been soaked with a seedling feed solution with an electrical conductivity (E.C). of 0.5 mmho, a pH of 5.8 and a temperature of 25 to 26°C. Always use quality rockwool rooting media.

The feed solution is prepared by diluting a standard tomato feed solution (approximately 2.5 mmho E.C.). A typical standard feed solution for tomatoes is presented in Table 1. The rockwool plugs must not be allowed to dry out or the seedlings can be severely damaged. The seedling feed solution at an E.C. of 0.5 mmho and a temperature of 25 to 26°C is used to wet the plugs as required. The goal is to maintain moisture levels in the plugs without water logging. As long as the feed solution is able to drain away from the bottom of the plugs, water logging should not occur.

A general rule is to apply feed solution just to the point where it just begins to run-off from the bottom of the plugs. The seedlings will require watering almost daily at this stage. Use light applications of the 0.5 mmho E.C. feed solution. The temperature to the root zone should be maintained at a constant temperature of 25 to 26°C for the first two weeks while the seeds are germinating and the young seedlings begin to establish. Air temperatures should also be maintained at 25°C.

The relative humidity in the nursery should be maintained at 75 to 80% (VPD* of 3 to 5 g/cm3) until the seedlings have emerged. The rockwool plugs are often covered by a plastic tunnel to help maintain the optimum humidity. Seedling emergence is usually complete within 10 days after seeding. Once all the seedlings have emerged the plastic tunnel is removed. Be sure to condition the plants to the greenhouse environment before removing the tunnel completely by. opening up the tunnel slightly to allow air to circulate by the plants for a few days prior to complete tunnel removal.

Supplemental light is applied to the emerging seedlings at 160 Watts/m2 for 16 to 18 hours per day (Fierro et al 1994, Portree 1996). This can be achieved by using 400 W (high pressure sodium) lights placed in rows 2 meters ( 6 feet) above the seedlings, with 3 meter (9 feet) spacings between the lights within the row. Adjacent rows of lights are spaced 3.5 meters (12 feet) apart.

Once the seedlings have emerged the root zone temperature is reduced to 23°C and the air temperature is maintained at 25°C. The relative humidity is reduced to 70 to 75 % (VPD of 5 to 6 g/cm3). Supplemental CO2 is delivered to ensure a target of 800 to 1000 ppm. Liquid CO2 is the preferred source because of its purity. The seedlings can also be misted once a day for the first 4 days after emergence. Apply the mist around mid-day since it is important the leaves are dry as the night approaches to avoid disease development. Continue to water with the 0.5 E.C. feed solution to ensure that the plugs are always moist.

Root zone temperatures are maintained by using bottom heating systems, located in close contact with the rockwool plugs. It is important to maintain optimal root zone temperatures throughout the entire cropping cycle, however, seedling tomatoes are particularly sensitive to cold temperature injury.

Experience has shown that when bottom heat systems have failed, even with temperatures falling only a few degrees Celsius for a few hours, seedling development has been set-back over a week. Even after apparent recovery of the seedlings, they remain developmentally delayed with weaker root systems when compared to seedlings maintained at optimal conditions. Tomatoes are sensitive to chilling injury throughout all stages of plant development, exposure to temperatures below 15°C will delay plant development, flower and fruit set (Foolad and Lin 2001).

First transplanting into rockwool blocks

The young seedlings are transplanted into rockwool blocks when the cotyledons (seed leaves) begin to touch or when the first true leaves appear. The rockwool blocks are soaked completely with full strength feed solution E.C. 2.5 mmho at approximately 23°C , just prior to transplanting.

As with sweet pepper seedlings, the young tomato seedling is rotated 90 degrees as the seedling is seated into the depression on the top of the rockwool cube. This operation layers the young seedling stem between the rockwool plug and the rockwool cube. Once the stem has been place in a "root" environment the stem reacts by developing roots along the layered portion of the stem. Drop the rootzone temperatures to 21°C just after transplanting.

Water the blocks daily (E.C. 2.5 mmho, 21°C) to ensure they remain wet, but avoiding overwatering. It should always be possible to squeeze some water out of the blocks (Portree 1996). Target root zone temperatures of 21°C for the next two weeks then the root zone temperature is lowered to 20°C. Air temperatures are maintained at 24°C during the day and 22°C at night, for a 24 hour average temperature of 23°C.

Supplemental lighting should be continued at 160 Watts/m2 for 16 to 18 hours per day. Carbon dioxide supplementation should continue maintaining a target of 800 to 1000 ppm. Combining CO2 enrichment with supplemental lighting in seedling tomatoes has be shown to increase seedling weight and to generally improve early yields (Flaherty et al 2000).

One week before the second transplanting into the production greenhouse, cut the supplementary lighting to 12 hours to condition the plants to the lack of supplementary lighting in the main production greenhouse. Plants not receiving this slight reduction in supplementary lighting tend to suffer from "light shock" when they are transplanted into the production greenhouse. This can set back their development approximately one week.

Once the seedlings have established in the rockwool cubes, monitor the E.C. of the cube two to three times a week. The E.C. will rise and can reach a maximum E.C. of 5.0 mmho. It is not advisable to allow the E.C. to rise beyond this point. The E.C. of the feed solution should be reduced to 2.0 mmho and the E.C. in the block should be then brought down to 3.5 mmho in advance of the second transplanting of the seedlings into the production greenhouse.

As the seedlings establish in the rockwool blocks, they have to be adequately spaced. Crowded plants will stretch becoming tall and spindly, resulting in poor quality transplants. The ideal transplant has a stocky appearance, with a stem diameter of about 1 centimeter at the surface level of the rockwool block. The young plants should be spaced on the table when it looks like the leaves are about ready to touch.

Plant density

Determining the plant density is a very important component of the greenhouse preparation and determines the number of seedling plants required for the production greenhouse. Plant density is directly linked with final yield and quality.

Too many or too few plants per unit area of production space will have a negative effect on yield and quality. Dense plantings tend to result in lower yields and smaller tomatoes as can sparse plantings. The point to remember is that there are optimum planting density targets and these targets can vary depending on cultivar, climate and available light.

Plant density targets for tomatoes actually change through the growing season in response to the differences in available light over the year. There is less available light at the beginning and end of the crop cycle corresponding to the shorter days and less intense light. A more open plant density is required at the beginning and end of the season and a denser planting during high light summer months in direct response to the changes in the available light. If a crop is planted at the optimum density for the summer months, it will be too dense for the early and late season.

Figure 3. When the spring light levels within the canopy become limiting for truss development, trusses will abort. This condition can occur in Alberta tomato greenhouses as a result of high spring planting density.

A density that is too tight during the early stage of the crop will result in insufficient light falling on each of the plants; each plant will not receive enough light to develop the flowering trusses.

Under conditions of limiting light early in the season, tomato plants will not develop flowers. The plant will continue to grow vegetatively, producing leaves and stems until light levels increase enough to support flower development and fruit set.

Later in the season, when light is limiting again, plantings that are too dense will limit how well the fruit is filled, resulting in smaller fruit, reduced quality and yields.

In contrast a more open canopy during the intense light of the summer will result in too much light falling on each plant, stressing the plant and resulting in smaller, shorter leaves as the plant moves out of balance. The plant will then have become too generative and there will be significant reduction in quality and yield.

Under the intense Alberta summers, more tomato plants are required to maintain a crop canopy able to produce enough leaves to intercept the light, shade the fruit, to protect it from sunscald, and maintain the humidity required for the plants to maintain the optimum balance for production.

The change in plant density is accomplished by "twinning" selected tomato plants in the greenhouse to allow a lateral stem to develop to a producing "main stem" to take advantage of the high summer light levels. As the season progresses towards fall, the twinned stem is removed to reduce crop competition for light. The process of twinning will be discussed in greater detail later in the manual under the section "pruning and plant training".

Plan for an early plant density target of 2.3 plants/m2, that will be increased to 3.5 to 3.7 plants/m2. Always be aware of what other growers in your area are doing with respect to planting density and recognize that different cultivars may have different requirements.

For example, some cultivars are particularly sensitive to low light levels early in the season and require a less dense, more open canopy in the early months. Be cautious about following recommendations from distant areas that have significantly different growing conditions as they may not apply directly to Alberta.

Setting up the greenhouse to receive the plants

Once the greenhouse has been thoroughly cleaned, the next stage is to lay down the growing media in rows to receive the plants. The sawdust bags or rockwool slabs are laid down in double or single rows to meet the requirements of the planting density target.

Using an example of a grower who is growing in sawdust bags;

The total number of plants required for the production greenhouse is determined by multiplying the production area (in square meters) by the planting density. An initial planting density target of 2.3 plants/m2 is reasonable for most beefsteak and cluster tomato cultivars.

Next, to determine the number of sawdust bags required, divide the total number of plants by the number of plants that can be grown in each bag. A standard greenhouse sawdust bag will hold approximately 20 Litres of sawdust and will have dimensions of 23 cm (10 inches) wide, 86 cm (34 inches) long and 15 cm (6 inches) tall when full. Two tomato plants are grown in each bag.

Now that the number of sawdust bags is known, the number of rows can be determined. There needs to be a walkway between each of the rows, the walkway is also where the pipe and rail heating pipes are located. Using the example for double rows, the walkway, the distance between bags from adjacent double rows is approximately 76 centimeters (30 inches). The distance between bags in the two adjacent single rows of the double row is approximately 20 centimeters (8 inches), with a total width of 70 centimeters (28 inches) for the full double row. Using this information allows for the determination of number of double rows that can be placed in the greenhouse.

Knowing the number of bags required and dividing this number by the number of rows (double rows preferred), you will arrive at the number of bags required per row to reach the target plant density (Figure 4). The number of bags in a row are spaced out evenly along the length of the row.

Figure 4. Sawdust bags set out in a double row.

Some growers prefer to grow in single rather than double rows. The determination of the number of rows required is accomplished in the same way as with double rows. Adjustments are made in the number of bags per row (increased) and with the walkway width (decreased) as required to meet the planting density target.

The decision to grow in single versus double rows has an impact on how the plants are trained during growing season. Individual tomato plants can grow up to 12 meters (40 feet) long over the course of the year. Knowing this, it is apparent that the plants can grow longer than any average greenhouse is tall. To accommodate this growth, much of the tomato stems are laid down along the length of the row beside the sawdust bags or rockwool slabs. The plants at the end of the row are trained around the end of the row to grow along the other side of the row.

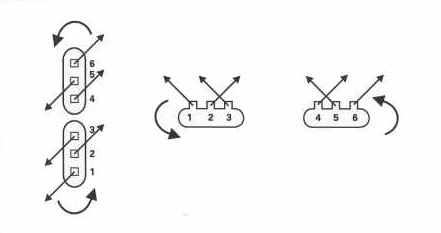

The single row system is often referred to as the V -training system (Figure 5). In the V - training system the first plant in the bag is leaned over and trained along one side of the row, in one direction, and the second plant is trained along the other side of the row and in the opposite direction. This pattern of plants being alternately trained to either the right or left side of the row continues along the entire length of the row.

Figure 5. Overhead and side views of the V-training system for tomato plants grown in single rows. Every second plant is trained in the same direction on the same side of the row. Adjacent plants are trained in opposite directions on opposite sides of the rows.

In the double row system all the plants in one side of the double row are leaned over and trained in the same direction along the row, with all the plants in the other side of the double row being trained in the pposite direction along the row (Figure 6).

Figure 6. Overhead and side views of the double row system for tomato plants. Every plant in each side of the double row is trained in the same direction along the length of the row. Once plants reach the end of the row they are trained around and down the other side of the row.

Hanging trough system

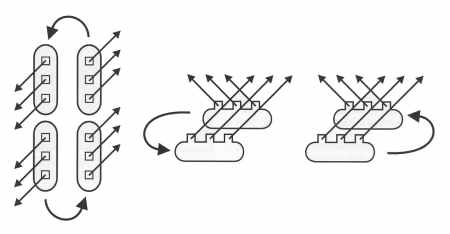

The hanging trough system is a variation on the single row system. The major difference is that the growing media is placed on troughs that are approximately four feet of the ground. The troughs are suspended from the roof and this places additional structural demands on the greenhouse. There is also additional expense associated with capital costs of the troughs.

The troughs are designed to catch the overdrain and channel it to the end of the rows. The plants are trained or down to the floor level before being trained to the overhead wire above the level of the trough.

Figure 7. The hanging trough system.

The major advantage of this system is that it can allow for the starting of a second crop before the old crop is completely finished and shorten the period that the greenhouse is out of production.

New plants can be introduced into the greenhouse and due to the height of the growing media, these young plants are not shaded by the established crop whose canopy is primarily located below the level of the trough. The young plants then establish while the established plants are still producing. When the new crop begins to produce the old plants are removed. There are variations on the theme of how the new plants are introduced and the old plants are removed that usually revolves on the introduction of the new plants and removal of the old plants throughout the entire greenhouse being accomplished in stages.

The use of the hanging trough system is not widespread in Alberta at this time. New growers are advised to study the local situation with respect to any advantages before immediately adopting the hanging trough system. It may be best to construct a greenhouse that can accommodate a hanging trough system but develop your crop production skills with the growing media on the floor. This will at least allow for a relatively easy transition into the hanging trough system at a later date.

Transplanting into the production greenhouse

The seedlings will be ready to transplant into the greenhouse at 5 to 6 weeks of age. The plants will have 7 to 8 true leaves at this point. Some growers place the plants on the plastic of the sawdust bags or rockwool slabs in the production greenhouse for the last week. The reason for this is usually a lack of space in the nursery as the plants require increased spacing.

Figure 8. Five week old tomato seedlings on the plastic and ready to be transplanted directly onto the sawdust.

The plants are placed in direct contact with the growing media when a number of roots are developing through the bottom of the rockwool blocks. It is important to place the seedlings in direct contact with the sawdust or rockwool slabs before the roots begin to grow horizontally along the plastic of the seedling table/sawdust bag/rockwool slab.

The goal is to ensure the roots go directly into the sawdust or rockwool to ensure firm rooting. Seedlings allowed to develop a horizontal root mass at the bottom of the rockwool cube before transplanting, do not establish as well into the final growing media.

Before the young plants are placed on the final growing media, the sawdust bags or rockwool slabs have to be saturated with feed solution so that the E.C. in the media is the same as is in the rockwool block of the seedling. This ensures that there is continuity of environment between the block that the roots are growing out of and the media that they are growing into. The target rootzone E.C. at this time is about 3.5 mmho. The temperature of the rooting media should be 20 °C at transplanting.

If sawdust bags are used for the final growing media, the bags should be filled with feed solution for one week prior to transplanting. This allows for the complete wetting of all the sawdust. Failure to properly wet the sawdust will result in the bulk of the sawdust bag remaining dry throughout the season resulting in a reduction in volume that the roots are able to occupy. Transplanting onto dry sawdust has demonstrated that only "cones" of wet sawdust develop directly beneath the irrigation drippers which are located at the top of the bag.

The sawdust bags are slit for drainage immediately after the young tomato plants are placed on to the sawdust media. Failing to slit the bags results in a very unfavourable waterlogged, anaerobic environment that will severely stall the plants.

The slits are approximately 4 cm (1.5 inches) long, and are made on the sides of the bags facing the drainage channel. One slit is made between every two plants. The slits run to the bottom of the bag to ensure complete drainage of the bags and to avoid any pooling of the feed solution at the bottom of the bag.

Once the plants are placed on the final growing media, the air temperatures are maintained at 20°C day and night, with a relative humidity of 75% (VPD of 3.5 to 5 g/m3) and liquid CO2 supplementation to 800 to 1000 ppm. One week after transplanting drop the night temperature to reach a minimum 18°C and maintain the 24 hour average temperature at 19.5°C. Ensure that rootzone temperature is a stable 20°C.

The goal at this time is to establish a strong vegetative tomato plant on the growing media with specific emphasis on the root system. Ideally the tomato plants will establish deep into the sawdust bags within two weeks.

Once the plants establish on the rooting media they tend to become overly vegetative or "bullish". The leaves at the tops of the plants tending to curl back on themselves towards the stem. Raising the 24 hour average temperature by 1°C to 20.5°C will direct the plant back into balance and set the stage for fruit production. The 24 hour temperature average should be returned to 19.5oC once the plants have come out of their "bullish" growth habit.

Figure 9. Overly vegetative, "bullish" young tomato plants.

A precise irrigation schedule is an important component of ensuring plant establishment and development of the root system. Feed at an E.C. of 2.5 mmho, target a 10 to 15% overdrain while delivering about 200 mls per plant per day. Schedule 7 irrigation events per day of about 30 ml per event starting at 9:00 am and ending at 3:00 pm. The strategy is to apply adequate water throughout the day, but to time the delivery of the water so that the roots grow to actively search for water between the watering events.

Looking at it from the other side, if water is applied almost continuously to the young plants so that there is no signal to the plant of a possible moisture deficit, there is no incentive for the plant to develop any more roots than it already has. If the plant is meeting its water requirements there is no need for it to expend more resources developing a more extensive root system. On the surface, this is a practical response to the environment, however, growers have other plans for their crop, plans that require the plant to put more resources into their root systems.

The more frequent the watering events, the less chance the plants will undergo any water stress. Some water stress is beneficial because it directs the plants to search for water by developing a more extensive root system. Young plants may not require a more extensive root system at this early stage of their development, but as the crop matures and fruit production begins, a extensive root system is prerequisite. Maintaining intensive production of fruit demands considerable mobilization and distribution of resources by the plants. The plant obtains the bulk of these resources through the root system.

The onset of fruit production is designed to coincide with the increasing light levels with the first harvest beginning in mid to late March. June is usually the month that Alberta sees a rapid increase in the amount and intensity of light received by the crop. The demand on the root system is proportional to the light received. If the root system is not ready to meet the demand caused by a heavy emphasis on fruit production under conditions of intense light, then wilting can occur.

Experience in Alberta has demonstrated that unless the young tomato plants are managed with a small amount of water stress to promote early root development, they will not possess an adequate root system when the high light period begins. The resulting stress typically causes wilting due to a undersized root system.

Increasing the amount of water delivered does not remedy the problem since the volume of water delivered is not the problem. In fact increasing the water volume delivered increases the problem by creating a situation of water logging which promotes the development of anaerobic conditions and disease. In hindsight the most frustrating aspect of this whole problem is that it can be avoided completely by careful management of the irrigation schedule of the young plants.

As the plants continue to grow, increase the amount of water delivered to maintain the 5 to 15% overdrain target by increasing the duration of each watering event rather than the number of watering events. As day length increases as the season progresses towards summer, increase the number of watering events to ensure the first watering is about 1/2 hour after sunrise and the last watering is about 1/2 to 1 hour before sunset.

Plant balance

The goal of greenhouse tomato production is to maintain the maximum sustainable yield of high value tomatoes for profit. Plant balance is defined as the partitioning of the resources of the plant towards vegetative growth, the production of stems and leaves and generative growth, the production of fruit. The optimum plant balance is the balance between vegetative and generative growth required in order to attain maximum sustainable yield.

Skilled growers learn to recognize the signals that indicate whether a plant is out of balance with too much emphasis on generative growth or vegetative growth. Thick stems and large long leaves with associated slow development of fruit are symptoms of a plant that is too vegetative. The development of leaflets at the end of a flowering truss is very diagnostic for overly vegetative plants. Thin stems, short leaves and small fruit that ripen quickly are symptoms of overly generative plants. An overly generative plant will eventually stall with insufficient leaf development to fill the fruit with an accompanying focus on setting more fruit.

The general approach to directing an overly vegetative plant back into balance is to increase the stress on the plant. Plants that are stress tend towards more fruit production. This is usually accomplished by raising the 24 hour average temperature by 1°C for a period of time, or by modifying the watering schedule to increase the duration between watering events. When adjusting the watering schedule it is important to maintain the optimum overdrain targets. The strategy is to adjust the timing of the watering events, not the amount of water delivered to the plants. Once the plants have been brought back into balance the temperature settings and watering schedules are returned to "normal".

To direct overly generative plants back to a more vegetative focus the approach is reversed. The 24 hour average temperature is reduced by 1 or 1.5°C and the watering schedule is adjusted to deliver more frequent waterings. The idea is to reduce the stress on the plants.

It is important to remember that once a plant begins to produce fruit its tendency is to produce more fruit. Also, as light levels increase, so does the stress on the plants and the generative focus also increases. For most of the producing season, the tomato plants will be tending more to a generative focus with more correction having to be applied to direct the plant to be more vegetative. Also remember that the greenhouse should be shaded with whitewash as the high light season begins in June or it can be very difficult to maintain adequately vegetative plant.

Pruning and plant training

Plant training

Tomato plants are trained to one stem that is physically supported by twine hanging from an overhead wire. The wires are located above the rows and run the length of the greenhouse and are usually placed one foot beneath the gutter height.

Figure 10. Plants supported by twine to an overhead wire.

The twines are attached to the young tomato stems using plastic "tomato clips" at about one week after transplanting. It is important that the young tomato plant be firmly rooted in the sawdust bag before it is clipped to the twine.

Figure 11. Plastic support clip being placed around a tomato stem.

The first plant training procedure after clipping the plants to the twine is to lean the plants in the direction that they will eventually be trained along the row. It is important to have the plant leaning before the first fruit set and begin to fill, as this allows for the all fruit to develop beneath the leaned stem.

By contrast, if the plants are allowed to set fruit while still vertical, the fruit will start to develop on the same side of the stem where the truss originates. As the plant grows in height and has to be leaned the trusses could completely twist off under the weight of the shifting fruit. The heavy fruit will all shift to the low side of the leaned stem.

Greenhouse tomato plants have tremendous growth potential with vines reaching up to 12 metres (40 feet) long during the growing season. Because of this potential the plants have to be properly pruned and trained to maintain an optimum plant balance and avoid unruly "wild" plants that will develop if the laterals are not pruned, resulting in excessive vegetative growth and development of multiple stems.

Tomato plants are fast growing under optimum conditions. Pruning and plant training are critical to plant management if an optimum plant balance is to be maintained that will result in high yield.

Pruning and plant training are ongoing tasks that must be scheduled to keep pace with the growth of the plants. There is really no catching-up with plants that have been allowed to grow too long without pruning. The plants can be brought back into balance, but not without some associated yield loss due to the plant resources which were directed into lateral stems that should have been pruned earlier.

Pruning

The standards for how to prune and manage the plants are set by the head grower and the implementation of the pruning standards is accomplished by the workers according to a schedule (Navarrete 1993). In larger greenhouses where there are a number of workers, efficiency of the plant pruning and handling tasks can vary by worker. Efficiency of workers improves when they are motivated; work organization can have a significant impact on motivating workers.

Assigning each worker an area of the greenhouse in which they are personally responsible for all the pruning and plant handling can help workers establish a sense of pride through ensuring that the plants are maintained to the highest standards set by the head grower. This also establishes an atmosphere of friendly competition as workers strive for the recognition of their peers for their personal high standards that are demonstrated by the performance of their section of the crop. This atmosphere of competition can be managed to help solidify a strong team of workers especially when workers are paid bonuses based on the performance of the crop.

When the pruning and crop management standards have been established by the head grower, it is also important to recognize that there will be variation in individual plants within the crop (Navarret and Jeannequin 1995). In general, management standards are usually based on the crop as a whole. The standards that will be discussed are examples of this ie. truss pruning to 4 fruit per truss after the first truss, maintaining a specific fruit to leaf ratio.

Automatically implementing these standards to all plants in the greenhouse does not recognize that there are weaker plants which can require individual modifications to the plant handling standard to shift the vegetative/generative balance in order to manage the weaker plants so that they can be strengthened.

The primary pruning and plant training tasks are: removal of lateral shoots, twisting the support twine around the lengthening stem, truss pruning, harvesting, plant lowering and removal of the older lower leaves. Plant twinning is another plant training technique that is used to increase the effective plant density by allowing a second lateral stem to develop on selected plants to produce fruit.

Pruning out the laterals and twisting the support twine is usually done twice a week. The lateral stems are pruned out as soon as they can be easily distinguished from the primary stem. Great care has to be taken to ensure that the plants are not "blinded" by removing the primary growing point. If this happens and if all lateral sems have already been removed, the productive life of the plant is terminated as the plant will no longer grow without the primary stem.

Starting a new plant as a replacement transplant is generally not effective because it will be too small to obtain the light it needs to develop properly in a canopy of larger plants. In addition, the young plant will receive the same amount of water as the larger plants which will be more than what it young needs and can result in water logging and development of root disease.

Truss pruning is also done as required during the twisting and pruning events. Truss pruning involves the removal of young fruit from the truss as a technique to maintain optimum plant balance. It ensures that the plant does not try to fill too many fruit and also that the fruit left on the plant can reach their maximum size potential.

Premium prices are paid for beefsteak tomatoes that reach either in the large and extra large grade categories and have optimum colour and are free of blemishs. The grade size categories are based on the diameter of the tomato fruit. (Reduced size translates to reduced grade and reduced price).

There are also optimum characteristics for cluster tomatoes. Generally the market requires clusters of 4 to 6 tomatoes with all tomatoes showing a touch of mature colour. The weight of the clusters should be between 454 to 680 grams.

The greater the number of tomato fruit that are allowed to set on any given truss, the smaller the fruit size. In addition, truss pruning is also important to maintain plant balance. If too many fruit are left to be filled, the plant will shift its resource allocation to preferentially fill fruit over developing the leaves and stem. If this pattern is left to continue, the plants will eventually "stall" with very little growth occurring. The result is a plant with numerous small fruit and short, small leaves. The plant with the greatest yield potential is the plant that allocates resources appropriately to developing new leaves and stems which are the prerequisite to continuous production of top grade fruit.

Normally a good balance for tomato plants would be approximately 20 - 25 fruit to 20 leaves, however this balance can vary with cultivar. Prune the trusses to allow 3 fruit to set on the first truss and 4 fruit per truss on the following trusses. As the plant continues to grow to the wire the optimum fruit to leaf balance outlined above will be attained.

It takes about 6 weeks from flowering to fruit pick under optimum light conditions. The first trusses can take 7 weeks to develop to harvest due to the lower spring light conditions. As the lower fruit are harvested new trusses flower and set, more fruit begins to develop, the balance of 20 to 25 fruit to 20 leaves is maintained with both the harvesting of fruit and the removal of leaves.

Leaf pruning, the removal of the lower leaves, is a distinct operation from the pruning of lateral stems. As the fruit develops on the stem it moves further down the stem in a relative sense as the subsequent truss develop from the growing point of the plant. The tomato plant canopy is usually maintained at 2 to 2.5 meters ( 7 or 8 feet) in height. As the plant continues to grow and lower fruit and leaves are removed, the plant is also lowered to maintain the canopy height. The lowering is consistent with the training process outlined in figures 4 and 5.

As growers develop more skill in assessing the productive potential of the plant, truss pruning can be based on the individual plant. For example, if the overall fruit size on a particular plant is smaller than the crop average, then it may be advantageous to allow only three fruit to ripen on one or two trusses, to direct more resources to the stem and leaves. Plants that have too many fruit will not fill the fruit to the optimum size, in addition the average leaf size will also shorten which in turn leads to even smaller fruit size.

Truss pruning works to balance a weak plant, to allow it to strengthen vegetatively which in turn allows for the fruit size to begin to increase (Atherton and Harris 1986, Navarrete and Jeannequin 1995). This technique allows growers to adjust the vegetative/generative plant balance of individual plants within the entire canopy. Even when the greenhouse environment has been set to optimize the plant balance of the entire crop, the status of individual plants can vary. Managing the number of fruit allowed to fill on individual plants is a technique that allows for the fine tuning of the entire crop to ensure optimum plant balance.

Canopy height

In the taller greenhouse structures, the overhead support wires can be as high as 3.5 meters (12 feet) above the floor. The height of the support wire defines the practical limit of the tomato crop canopy height. Under the low light conditions of the early spring in Alberta, some growers will allow the tomato canopy to reach the 3.5 meter (12 foot) level in order to ensure that the developing fruit can size up and are ready for harvest without coming in contact with the floor.

Maintaining a canopy height is only practical when there are systems in-place which allow for working in such a tall crop. The most common approach for working tall crops is to use electric carts with adjustable platforms that allow workers to ride the carts along the row, using the heating pipes as the rails. The pipe and rail system is discussed in more detail in the companion publication "Guide to commercial greenhouse production in Alberta".

Although it is possible to maintain a tall tomato crop canopy throughout the entire growing season, it is not recommended. As the summer approaches, with its high light levels it is recommended crops be lowered to maintain a maximum canopy height of about 2.5 meters (8 feet).

The greenhouse environment can stratify under the hot, light intense Alberta summers. The higher you go in the canopy, the hotter it gets. Tomatoes are particularly sensitive to high temperatures; if plants are allowed to grow too tall, the temperature signals to the top portion of the plant are not the same as to the lower.

Depending on the ability to control the greenhouse environment, it may not be possible to provide a uniform temperature regime to the entire plant in a tall canopy. Setting the computer sensor at the top of the plants may allow for maintaining temperatures for the optimum plant balance there but could result in temperatures in the lower canopy being too cool. As a result the lower canopy to become too vegetative, the tomatoes size up more slowly but reach a larger size before ripening. If the sensors are placed in the canopy of the tall crop, the tops of the plants will then generally be exposed to higher temperatures than desired thus becoming overly generative.

A canopy height of 2.5 meters (8 feet) will allow a more uniform temperature signal to the entire plant, which in turn makes it easier to maintain an optimum plant balance throughout the crop.

If the crop canopy was allowed to develop beyond the 8 foot level, it is gradually lowered to the 2.5 meter (8 foot) level in late May or early June. Lowering is accomplished as the lower fruit are harvested and the lower leaves removed. A lower plant canopy is possible under high light conditions because the fruit develops faster and is harvested sooner than under low light conditions.

All factors considered, the determining factor on canopy lowering is the canopy height must be maintained so that the lowest, most advanced fruit do not contact the floor.

Twinning to increase crop density

As the crop moves into the summer season, the increased light intensities and associated increase in temperature serves to put more stress on the plants. Increased stress directs the plants to become more generative. The increased generative focus results in shorter, smaller leaves and less growth to the stems. Over time and without correction, the crop canopy becomes sparse, the fruit do not fill properly and are exposed to the direct sunlight which results in further quality problems associated with overheating, shrink cracking and blossom end rot.

As the light levels begin to increase with the progression from spring to summer, twinning allows growers to increase the crop density to take advantage of the higher light levels to increase production, and allow for more leaves to shade the fruit and maintain fruit quality.

Twinning should take place approximately 10 weeks after seeding. The plants are selected for twinning to ensure that the increase in plant density is uniform throughout the crop. For the twinning to be successful, strong plants have to be selected to carry the extra stem. If weak plants are selected the plant will not be able to support the second stem and yield will be compromised. In addition, weak twins will not be able to properly fill in the canopy required for the crop to reach maximum yield and collectively resist the stress of the intense sunlight. The result will be plants that are that are out of balance and too generative.

Selection of plants suitable for twinning is based on an assessment of vegetative vigour. Strong plants will have relatively bigger leaves and thicker stems near the top of the plant. A good rule of thumb in selecting a plant is to measure the first fully expanded leaf located near the head (growing point) or top of the plant. This leaf should be at least 45 cm long for the plant to be considered suitable for twinning.

Flowering

Flowering is a prerequisite to fruit development and delays in flowering generally result in delayed fruit production (Atherton and Harris 1986). It is important for growers to understand the process of flower development and how maintaining optimum growing conditions ensures flower development for maximum sustainable yield.

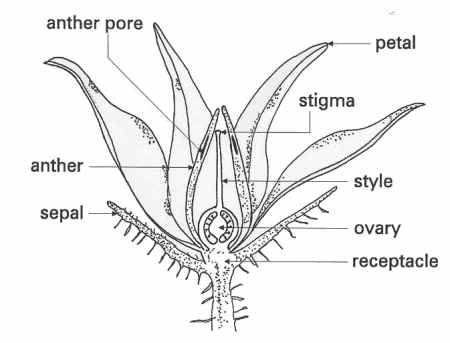

Figure 12. Diagram of a tomato flower

Flower initiation in tomato begins within three weeks of the expansion of the cotyledons, specifically coinciding with the third oldest true leaf reaching one centimeter in length (Atherton and Harris 1986). In the very early stages of flower development the flower is very small, a barely noticeable bump on the stem length (Atherton and Harris 1986).

Flowering in seedlings is inhibited by low light levels, reducing light levels from 10,000 to 2,500 lux (approximately 100 to 25 W/m2) has been shown to delay flower initiation by up to 29 days, allowing up to seven more leaves to be produced before the first flower was initiated (Atherton and Harris 1986). This is another strong argument for the use of supplemental lighting during the seedling production stage.

Figure 13. A double truss.

The environment of the shoot can have a significant effect on the number of flowers that are initiated on an inflorescence (Atherton and Harris 1986). The 24 hour average temperature is the primary temperature factor that is important for controlling flowering (Atherton and Harris 1986) This suggests that higher day temperatures can compensate for cooler night temperatures (Atherton and Harris 1986). However, branching of the inflorescence or "double trusses" occurs at temperatures below 13oC (Atherton and Harris 1986). Lower night temperatures also have an effect on flower morphology, increasing the number of petals and stamens (Atherton and Harris 1986).

High temperatures or low light conditions can promote the exsertion of the style from the anther cone resulting in a reduction of pollination and an increase in flower abortion due to failure to pollinate (Atherton and Harris 1986, Ho and Hewitt 1986). Improved cultivars and the high fertility regimes of greenhouse production, including CO2 enrichment, have largely overcome the detrimental effect of low light on pollination (Ho and Hewitt 1986). Reduced pollen viability is also a major cause of poor fruit set at high temperatures (Stevens and Rick 1986).

After the flowers on a truss have been initiated, the rate of flower development is primarily determined by temperature with more rapid development at 20°C (Atherton and Harris 1986). High incidences of flower abortion has been observed when temperatures reach 21°C (Atherton and Harris 1986).

Elongated trusses tend to develop under low spring light levels of in Alberta. Under very low light levels trusses can even fail to develop, a condition that can depend on the light requirements of the variety and is influence by heavy canopies associated with planting densities that are too high. It is always advisable to consult your seed supplier regarding the specific requirements and cultural recommendations for the cultivar you are growing.

Tomato plants under favourable light conditions that are water stressed or stressed by excessive E.C. levels in the root zone can exhibit reduced rates of flower development (Atherton and Harris 1986). Conversely, under low light conditions, slight water stress can act to promote flower development (Atherton and Harris 1986).

Flower initiation begins very early in the seedling stage of the tomato plant. Poor temperature management and low light levels can have a significant negative impact on flower development and yield of the crop. The rate of flower initiation and development is strongly influenced by the environment of the stem. It is important to maintain the optimum 24 hour temperature average for tomatoes in the greenhouse environment to optimize the development of the plant and crop as a whole. This optimum temperature is also ideal for flower development. It is also clear that low temperatures at the growing point can have a negative effect on flower development which indicates a need to ensure optimum temperatures are maintained at the tops of the plants.

In the early months of the production cycle it is possible to have cold spots in the greenhouse or temperature fluctuations at the tops of the plants even when the sensors are indicating that optimum temperatures are being maintained. Oversized flowers, flowers with too many petals and other morphological abnormalities and dual trusses are all indicators of cooler than desired temperatures to the flowers during early stages of their development. Low temperatures during flowering and pollination can also result in fruit deformities (Portree 1996). The use of heating pipes at the tops of the plants can ensure the optimum temperatures for flowering and flower development are maintained.

Carbon dioxide supplementation up to 1200 ppm does not have an influence on the number of flowers formed; although carbon dioxide supplementation under the low light conditions that are commonly experienced in the winter and early spring has been shown to accelerate flower growth in the first inflorescence and reduces flower abortion (Atherton and Harris 1986).

A word of caution when using carbon dioxide generated by combustion, watch for potential negative effects of pollution. Ethylene can be a by-product of combustion, especially in situations where there is incomplete combustion of the fuel. Tomato flowers are very sensitive to ethylene between the bud stage and anthesis. Ethylene levels at 0.5 ppm during these stages are sufficient to cause flower abortion (Atherton and Harris 1986).

Pollination

Pollination is the critical event where receptive flowers begin to develop fruit. The tomato flower has both male and female structures. The male structures are associated with pollen development and include the anthers, which hold the pollen. The female structures include the stigma, the structure that receives the pollen, and the ovary that eventually develops into a fruit if pollination takes place.

In the development of the tomato flower the stigma becomes receptive to pollen one to two days before the anthers actually start to shed pollen, and remains receptive for a total of six to eight days (McGregor 1976, Ho and Hewitt 1986). The stigma is receptive to its own pollen (self pollination) or to other pollen (McGregor 1976).

Pollen grains must also adhere to the stigma so the pollen can fertilize the ovary. Adherence of the pollen to the style may be reduced below 70% relative humidity or if temperatures are outside the range of 17 - 24oC (Ho and Hewitt 1986). Pollen release can also be reduced under high humidity (Portree 1996), experience in Alberta greenhouses has demonstrated that tomato pollen release is impeded when the relative humidity approaches 85%.

Although modern greenhouse tomato cultivars are self pollinating (Ho and Hewitt 1986) tomatoes require some form of mechanical pollination in order for the crop to attain optimum yield (McGregor 1976). Any mechanical disturbance of the tomato flower will cause some release of pollen and improve the overall pollination levels in the crop (Portree 1996).

Battery powered electric "bees" have been a popular form of mechanical pollination. These are used to vibrate the flowering trusses to release the pollen. Tomato pollen is more readily released under bright sunny days and when the temperatures are above 20°C, conversely cool cloudy weather reduces the release of pollen (McGregor 1975, Portree 1995). When electric vibrator pollination is used, the plants must be pollinated every second day throughout the cropping season (Portree 1996).

Figure 14. An electric "bee" pollinator

The use of bumble bees, both the western bumble bee (Bombus occidentalis) and the eastern bumblebee (Bombus impatiens) as pollinators in tomato greenhouses has almost completely replaced the use of the electric bees. Bumble bee hives can be purchased from commercial suppliers. Usually 7 hives per hectare (3 hives per acre) are sufficient to ensure complete pollination throughout the tomato crop (Portree 1996).

Figure 15. Bumble bee hives for pollination can be purchased from commercial sources

The association between bees and flowers is long, going back 100 million years to the middle of the Cretaceous period (Winston 1987). In short, bees know flowers. Based on observations in Alberta tomato greenhouses, the use of bumble bees as pollinators can result in an approximate 10% increase in yield over using electric bees for pollination. Bees are in the business of collecting pollen and nectar, and visit tomato flowers when the flowers are most ready to release the pollen.

Bumble bees are not normally aggressive and will not sting unless the hive is disturbed or if individual bees are squeezed (Portree 1996), which can occur if bees get caught up in the clothing of workers. The eastern bumblebee is relatively more aggressive than the western bumblebee and tends to be more sensitive to people standing close to the hive. It is important to know whether any staff working in the greenhouse are allergic to bee stings and to consult with medical authorities to ensure that all necessary precautions are taken to be able to appropriately respond to a bee sting incident.

Know the requirements of bumble bees and how to manage the hive for maximum pollination. Detailed instructions on hive placement and installation, as well as care and maintenance of the colonies can be obtained by the supplier. Specific recommendations can vary with bee species, but there are some general considerations for care and management.

Using bumblebees as pollinators in greenhouse tomato crops is more easily accomplished in conjunction with biological pest control programs. Bumblebees are extremely sensitive to insecticides and can be adversely affected by fungicides. If you have to use a pesticide always consult with your bee supplier or an extension specialist to determine how to minimize the negative effects to the bees. Be aware that with many pesticides there will always be a negative effect on the bee pollinators and sometimes these effects can be long term.

As tomato flowers don't produce nectar (Portree 1996), the bees require a feed solution as a nectar substitute. The feed solution comes with the hive and usually is sized to last the productive life of the hive.

Figure 16. Tomato flower with a bruise on the anther cone indicating that the flower has been visited by a bumble bee.

Ensure that the hives are placed about 1.5 meters off the ground and is placed in the canopy to shade it from direct sunlight (Portree 1996). Warning signs must be posted at the entrances to the greenhouse to inform visitors that bumblebees are used as pollinators in the tomato crop.

Monitor pollination levels two to three times a week to assess the performance of the hive. When bumblebees visit and pollinate a tomato flower they leave bruises on the anther cone of the flower. This bruise can be used as proof of pollination . To assess the level of pollination collect at least 20 withered flowers from 4 to 5 areas within the greenhouse and determine the percentage of pollinated flowers. Pollination levels should be 80% or better, high yields depend on high pollination levels. Contact your supplier when pollination levels fall below 80% as this is an indicator that the hives are not performing adequately and may be in decline.

Fruit set and development

Consistent high fruit set is a prerequisite to high yield (Ho and Hewitt 1986), and pollination is the prerequisite to fruit set. Pollen germination is temperature dependent and takes about 1 hour at 25°C (Ho and Hewitt 1986). Pollen must adhere to the stigma to allow germination to take place. If the relative humidity is below 70% or the temperature is outside the range of 17 - 24°C, the adherence of pollen on the style may be reduced (Ho and Hewitt 1986). The rate of fruit development is dependent on temperature. Optimum day temperatures range between 18 to 20°C with night temperatures dipping to 15 to 16°C to meet the optimum 24 hour average temperature of 19.5 to 20°C. The optimum night temperature for fruit set is in the range of 15 - 16°C (Ho and Hewitt).

With reasonable temperature control, neither pollination nor fruit set are limiting for fruit production under greenhouse conditions provided that light levels are adequate. With the development of tomato cultivars that perform well under conditions of high fertility and CO2 enrichment the detrimental effect of poor light on pollination in winter has largely been overcome (Ho and Hewitt 1986, Portree 1996).

Poor fruit set on apparently healthy plants depends on the climatic conditions prior to and at the time of pollination. Flower abscission (blossom drop) shortly after anthesis is the most common symptom of failure of the flower to pollinate and set fruit (Wittwer and Honma 1986). Low light intensities, short photoperiods and high night temperatures are important limiting factors to fruit set (Wittwer and Honma 1986). The temperature 3 days prior to anthesis has been shown to have the biggest effect on flower set. Even without style elongation, fruit set at high temperatures is often very low. This suggests that pollen germination and growth of the pollen tube may be disrupted at high temperatures (Wittwer and Honma 1986).

High temperatures, low humidity and low moisture increase blossom drop. During periods of high temperature and low humidity the flower style elongates prior to dehiscence and can result in the flower failing to pollinate if the stigma extends beyond the stamen cone. The resulting damage to the surface of the stigma makes the stigma unreceptive to pollen (Wittwer and Honma 1986).

Fruit size is reduced by water stress, mainly as a result of a decreased fruit growing period (Ho and Hewitt 1986). Fruit size can be similarly reduced by excessive electric conductivity (E.C.) in the rootzone. Both the sugar concentration and acidity of the fruit are increased by high conductivity of the feed solution.

The fruiting truss is supplied mainly by the subtended leaves, the leaves immediately below the truss. In the tomato plant, the movement of assimilate from a particular leaf, and the sources of supply for a truss changes as the plant continues to develop. The relationship between leaves as organs that supply assimilates for growth of the fruit, plant, and established leaves as the sources of this assimilate is termed source/sink relationships and define the assimilate supply and demand for the plant and can be quite complex (Ho and Hewitt 1986).

When the supply of assimilate is limiting there is competition between trusses, the growth of a fruiting truss can suppress the flowering of later trusses (Ho and Hewitt 1986). In general, successive trusses flower at 6 - 7 day intervals, but delays of up to a month in the development of later trusses can occur under conditions of limiting assimilate (Ho and Hewitt 1986). There is an accelerated growth rate of the fruit under CO2 enrichment (Wittwer and Honma 1986).

Maximum profit depends on more than just yield and is a function of yield and quality. Tomato quality can be defined as those characteristics of the fruit that are demanded by the market. Quality characteristics include; size, shape, colour, firmness, taste, texture and solids content (Ho and Hewitt 1986). Beyond ensuring the plants are managed to produce the maximum number of fruit that meet the required grade for optimum quality, maximum profit is a function of supply and demand.

Prices are usually at their lowest for greenhouse tomatoes during the summer months when the field tomato crop is in production. The profit picture for a greenhouse tomato grower depends on the overall supply of tomatoes from both greenhouse and field production. Regardless of the supply of tomatoes on the market, the higher prices generally go to the fruit with the highest quality.

Harvest

The fruit of beefsteak tomaotes is preferably harvested at colour break, where a yellow-orange colouration is evident at the blossom end of the fruit. At the very minimum the tomato fruit must be at least at the mature green stage before harvesting.

Figure 17. Colour break is the point where the fruit begin to take on a hint of their mature colour.

As with all quality characteristics, the market is the ultimate authority on determining when to harvest. Growers will adjust the harvest colour standard based on the market they are serving. The further the distance to the market, the more likely the tomato fruit will be harvested with less colour showing. The nearer the market, the more colour showing at harvest. Individual growers with a specific niche at specialty markets may leave the fruit on the vine to almost ripen completely.

It is quite common for the first fruit that reach mature size on the plant to be slow to ripen with a tendency to continue to increase in size with no indication of colour break. In this situation a strategy to coax the fruit to ripen is to remove the leaves that are below the truss and one or two leaves above the truss, exposing the fruit to the direct sunlight.

Cluster tomatoes are harvested when all tomatoes on the cluster have reached colour break which then implies that some of the tomatoes will be more advanced in ripening. There are also requirements for the number of tomatoes on the cluster, usually not less than four and no more than six. These requirements for the numbers of tomatoes also has implications for how much the clusters or trusses can be pruned early in the development of the cluster as a management strategy to ensure the optimum plant balance.

The individual clusters of 4 to 6 tomatoes are bagged before they are sent to market. Bagging allows for the ease of handling by the consumer and ensures fruit are not lost from the cluster as the tomatoes are transported home. This bagging also requires extra effort at the greenhouse or packing shed over and above what is required for the tray packing of beefsteak tomatoes.

How the tomatoes are handled at harvesting also impacts the presentation of the tomato at the market. Careful handling will increase the shelf life of the tomato (Portree 1996), primarily by avoiding physical damage to the fruit which increases the probability of more rapid spoiling.

Important handling precautions include minimizing the height that the tomatoes are dropped into the harvest basket and picking early in the morning when the fruit temperatures are cooler than under the heat of the day (Portree 1996). It is also important not to overfill the harvest baskets as fruit can be damaged when the baskets are stacked on the pallets for transport to the packing shed.

Table 2: Ranges of vitamin and mineral components of ripe tomato fruit constituents per 100 g of fresh tissue

| Constituent | Normal Range | Unit |

| Dry matter | 4.71 - 8.3 | grams |

| Vitamin A | 192 - 1667 | IU |

| Vitamin B1 | 16 - 80 | æg |

| Vitamin B2 | 20 - 78 | æg |

| Vitamin B3 | 280 - 340 | æg |

| Vitamin B6 | 50 - 150 | æg |

| Niacin | 0.3 - 0.85 | mg |

| Folic Acid | 7.4 - 8.6 | mg |

| Vitamin C | 8.4 - 59 | mg |

| Potassium | 92 - 376 | mg |

| Phosphorus | 7.7 - 53 | mg |

| Calcium | 4.0 - 21 | mg |

| Magnesium | 5.2 - 20.4 | mg |

| Sodium | 1.2 -32.7 | mg |

| Iron | 0.2 - 0.95 | mg |

| Aluminum | 0.5 - 2.95 | mg |

| Boron | 0.04 - 0.13 | mg |

| Copper | 0.05 - 0.2 | mg |

| Lead | 0.02 - 0.05 | mg |

| Manganese | 0.04 - 0.05 | mg |

| Zinc | 0 - 0.25 | mg |

| Chlorine | 24 - 69 | mg |

| Nitrate | 1.3 - 30 | mg |

| Ash | 0.51 - 0.7 | grams |

From Redenbaugh et al, 1992

The goal with determining when to harvest is to harvest with an eye on presenting the highest quality tomato in colour, size, shape, smell and free of blemishes at point of contact with the consumer. When consumers buy tomatoes they use their senses of sight and smell to judge the quality and taste of the tomato, and after some consideration of price, a selection is made.

Beat-up, ugly tomatoes don't sell as well as near perfect tomatoes, no matter how well they might taste. However, it also true that consumers do have a memory for how well the last tomato tasted the next time they are in the produce department, so the best looking tomatoes still have to perform well on the table.

Table 3: Nutritional Value of ripe tomato fruit per 100 grams of fresh tissue (Recommended Daily Allowances, RDAs)

| Nutrient | Percent contribution to the

total nutrient supply from tomato |

| Protein | 0.8 |

| Vitamin B6 | 3.5 |

| Vitamin A | 9.5 |

| Vitamin C | 60 |

| Thiamin | 3.2 |

| Riboflavin | 1.3 |

| Niacin | 3.1 |

| Ascorbic acid | 12.2 |

| Magnesium | 2.6 |

| Calcium | 0.9 |

| Iron | 15 |

From Redenbaugh et al, 1992

Always bear in mind when the tomatoes are harvested they are destined for someone's table The act of the harvest should be considered as one of the very early stages in the preparation of a meal. Be aware of the food safety requirements of your market. Understand that there is more and more emphasis on ensuring the safety of the food supply which includes accountability for how the produce was grown and handled in the greenhouse.

Food safety requirements include certain design specifications of the fruit handling areas to ensure that the fruit do not come in contact with soiled surfaces. The picking baskets have to be washed regularly and greenhouses must ensure that workers handing the produce have ready access to wash facilities which makes it easier to maintain clean hands while fruit is being handled.

Table 4: Variation in amounts of carotenoid pigments in ripe fruit per 100 grams of fresh tissue.

| Constituent | Range among six

tomato cultivars |

| Phytoene | 9.8 - 29 |

| Phytofluene | 2.1 - 15.5 |

| -carotene | 1.4 - 11.9 |

| -carotene | 0.5 - 2.6 |

| Lycopene | 43.6 - 181.2 |

| Values in æg/g fresh tissue. |

From Redenbaugh et al, 1992 |

|