| | Livestock manure has been recognized for millennia as a valuable source of nutrients and a good soil conditioner when applied to farm land. However, mismanagement of the large quantities of manure generated by intensive livestock operations can adversely affect soil and water resources. Manure analysis, soil testing, and application rates based on crop needs are the keys to a successful manure nutrient management plan.

Manure happens

Livestock production - including cow-calf operations, beef cattle feedlots, dairies, hogs, and poultry for meat and eggs - is an important sector of Alberta’s agricultural industry. During the past two decades the province’s livestock industry has experienced significant growth. The cattle herd, for example, has increased by more than 5.76 million animals in 1999. Assessments of future market potential support further growth in the primary and processing sectors of the agricultural industry in general, and the livestock industry in particular.

Intensive livestock producers must manage waste by-products as well as their primary commodity to maintain viable operations. Manure production has become a significant challenge, because of larger herds and because a greater proportion of livestock are concentrated on fewer, larger operations.

The Alberta cattle herd in feedlots alone may produce as much as 2.1 million tonnes of manure a year.

What we normally consider livestock manure is actually a highly variable mixture of feces, urine, soil, bedding material, and wash water. Its characteristics depend upon the type of animal being raised, its diet and bedding, the manure handling system, and even the climate. The nutrients in manure, such as nitrogen and phosphorus, occur in both organic and inorganic forms, though organic nutrients must first be converted or mineralized to inorganic forms before plants can use them. This conversion process is carried out by micro-organisms and other biota in the soil.

Application on crop land is the most common and efficient method of handling livestock manures. However, without proper management, manure application over a period of years can cause a build-up of nutrients and salts in the soil. Excess manure can contaminate groundwater when soluble nitrate and salts leach through the soil. Runoff from manured land can carry phosphorus, nitrogen, organic sediments, and pathogens to surface water bodies.

Manure odours, depending on manure type, application method and location, can also have adverse effects on nearby residents and property values. Other air quality concerns include the release of greenhouse gases (carbon dioxide, methane, and nitrous oxide) during manure storage, processing, and land application.

Protecting soil and water

Agriculture can have a significant effect on the environment in terms of water, soil and air quality. Livestock manure, in particular, has been identified as a major environmental problem when applied in excessive amounts, or in sensitive landscapes. Adopting a good manure nutrient management plan can minimize or even prevent negative effects on the environment and promote a more sustainable agricultural industry.

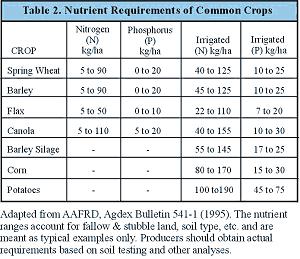

The fundamental principle of good nutrient management is to use manure application rates that are based on the actual nutrient content of the manure (Table 1) and the specific requirements of the corps being grown (Table 2). Though averages are helpful, actual testing is very important, as nutrient content can vary widely.

Unfortunately, the nutrient balance in manure does not usually match the nutrient balance required by most corps. When manure is applied on the basis of plant nitrogen requirements, the phosphorus content of the manure is excessive. If manure is applied on this basis for several years, phosphorus can accumulate in the soil surface and become a serious risk to surface-water quality. Subsequent soil testing in the second and possibly third year may partly reflect the influence of residual nutrients on soil fertility levels.

If manure is applied on the basis of phosphorus requirements, nitrogen levels are usually not being met. While nitrogen can be applied in other forms, manure application rates based on phosphorus usually require at least twice, and often four or five times the land base.

How to use manure

Development of a good manure management plan is a four-step process. It requires;

- determination of the total amount of manure being produced;

- analysis of the manure’s nutrient content;

- soil testing: and

- an understanding of crop fertilizer needs.

Total manure production can be estimated by weighing and counting the number of truck loads of manure removed over a given period of time. The amount of liquid manure can be estimated in terms of volume at the time of removal or by measuring the size of the holding facility.

Representative manure samples should be collected at the time of application and sent to a commercial soil-testing laboratory for nutrient analysis. Producers should keep samples cool and ship them to the laboratory as soon as possible. Contact the laboratory to discuss sampling procedures, sample storage methods, and the costs of analysis.

At a minimum, analysis should be conducted for annomium-N (NH4-N), total nitrogen (TN), total phosphorus (TP), and moisture content. The difference between TN and NH4-N is equal to the organic nitrogen content of the manure. Manure analysis should be carried out over a number of years in order to develop a database for your operation.

Soil testing should also be conducted on a regular basis as conditions can change from year to year. Recommended soil sampling procedures include collecting samples that represent the majority of the field, taking samples from the 0 to 15 cm, 15 to 30 cm, and 30 to 60 cm depths, air drying samples as soon as possible, and storing samples in cool conditions before shipping. Fertilizer recommendations reflect such factors as soil type, crop yield, and nutrient levels. Consult a soil-testing facility for help.

Crop fertilizer recommendations are generally based on yield responses to commercial, inorganic fertilizers, under different soil types and management systems (e.g. irrigation versus dryland). However, all of the nutrients in commercial fertilizers are immediately available to plants, whereas only a portion of the nitrogen and phosphorus in manure is available in the first year after application.

In most cattle feedlot manures, for example, about 25% of organic N, 100% of the NH4-N (less any gaseous losses), and 50% of the total phosphorus are available for crop uptake during the first year after application. The residual nutrients, mainly in organic forms, are carried over for three to four years and only slowly become available for plant use.

A significant portion of the nitrogen can be lost from manure before it is applied to the land. Much of this is caused by the gaseous loss of ammonia (NH3). This process occurs in the feedlot pens and during storage. Ammonia loss will also continue after manure is applied to crop land. Research has shown that incorporation of manure into the soil within the first 48 hours minimizes the gaseous loss of ammonia to about 15%. Delaying incorporation will mean greater losses. Injection of liquid manure can also greatly reduce gaseous loss and retain more nitrogen for crop use. Equipment should be calibrated based on the application method so the correct amount is used.

Producers should aim for maximum yield when using manure as a nutrient source. However, economic factors, such as fertilizer cost and crop prices, should also be considered when using a combination of commercial fertilizers and manure.

Example of a manure nutrient calculation

Suppose an irrigated field to be planted with barley silage requires 95 kilograms of nitrogen per hectare. The producer has solid cattle manure, which contains 10 kilograms of N per tonne (1.0%) and 2.6 kilograms of NH4-N per tonne (0.26%) on a wet-weight basis. The manure is incorporated within 48 hours, therefore it can be expected that about 15% of the NH4-N will be lost through volatilization. Greater NH4-N losses would occur if incorporation was delayed. To calculate the application rate:

- Determine the amount of organic N:

- Determine available crop N in the first year after application:

Thus the manure application rate for this example is 95 kg/ha ÷ 4.06 kg/t = 23 tonnes/hectare.

Thus the manure application rate for this example is 95 kg/ha ÷ 4.06 kg/t = 23 tonnes/hectare.

It should be noted that several years of application based on nitrogen will cause a build-up of phosphorus. It is important to prevent phosphorus from accumulating much beyond the levels needed for crop yield response. However, phosphorus-based manure application rates will require additional land for spreading.

Photo: Land application is an effective means of using manure. Livestock manures are good nutrient sources and soil conditioners, but need to be managed responsibly to prevent damage to soil and water resources.

Other Beneficial Management Practices

- Store manure away from any water body. Runoff from pens and stored manure must be contained.

- Never apply manure on land next to streams, ponds, irrigation canals or other water bodies. Observe set-back guidelines. For example, don’t apply manure within 45 metres of a major break in slope to a watercourse. Consult local land use guidelines and bylaws for specific widths of buffer zones that should be observed near water bodies.

- Nitrogen and salts can rapidly leach through sandy soil and into shallow water tables. Take special care when applying manure on these coarse-textured soils, especially where the water table is less than two metres below the soil surface. This is particularly important under irrigation or in regions with high rainfall.

- Sample soils annually to check for the build-up of excess nitrogen and phosphorus. Regular soil sampling can reduce nutrient build-up, save money on excess fertilizer, and increase crop yields, as well as protect soil and water quality.

- Never apply manure on snow or frozen soil.

- Consult your neighbours regarding the timing of manure application. This simple courtesy is not only a friendly gesture, it may prevent conflicts associated with manure odour.

- Keep accurate records; they are critical for a long-term nutrient management plan. Manure production estimates, manure analyses, soil test results, application rates and dates, and identification of the parcels of land that received the manure should be kept in a set of well organized records. Over time, this information will provide a valuable database, unique to your operation.

Use regular soil testing to monitor soil quality in fields with a history of manure application and to show which nutrients are required. Specific concerns include the accumulation of phosphorus and salts. Consult AAF Agdex Bulletin 553 (1987) for more information on getting the most from your soil test report.

Key points for a manure nutrient management plan

- Determine amount of manure produced.

- Determine nutrient content of manure.

- Obtain soil-test recommendations.

- Calibrate application equipment.

- Incorporate manure as quickly as possible.

- Monitor soil nutrient and salt levels.

- Account for residual nutrient carryover when calculating application rates.

- Identify sensitive landscapes with respect to groundwater and surface water vulnerability.

- Keep accurate and detailed records.

This fact sheet on Manure Nutrient Management is one of a series of information bulletins on agriculture and resource management produced by the Water Resources Branch, Alberta Agriculture and Rural Development. For more information contact Barry Olson of the Water Resources Branch, at (403) 381-5884 or use the Alberta Government Riteline, toll-free, at 310-0000.

IB004-2000

|

|