| |

Pre-cooling rapidly lowers the temperature of freshly harvested produce and is done immediately following harvest to minimize spoilage. There are five principal methods of pre-cooling fresh produce:

- room cooling

- forced-air cooling

- hydro-cooling

- ice cooling

- vacuum cooling

Considerable loss in quality and shelf life can occur as a result of holding harvested produce in the field before pre-cooling. All methods require sufficient refrigeration capacity to reduce the temperature of the produce within the required time plus the ability to remove the normal heat gain in the facility. Table 3 outlines the recommended methods for pre-cooling fruits and vegetables and is followed by a brief description of each of the pre-cooling methods.

Table 3. Recommended Pre-cooling Methods for Fruits and Vegetables

| # | Product | Pre-cooling Method | # | Product | Pre-cooling Method |

| 1 | Asparagus | hydro-cooling, ice cooling | 19 | Peas | forced-air cooling |

| 2 | Beans (green, wax) | forced-air cooling, hydro-cooling | 20 | Peppers | room cooling, forced-air cooling |

| 3 | Beets | room cooling | 21 | Potatoes (mature) | room cooling, forced-air cooling |

| 4 | Broccoli | ice cooling, hydro-cooling | 22 | Potatoes (new) | room cooling, forced-air cooling |

| 5 | Brussel sprouts | forced-air cooling | 23 | Pumpkins | room cooling |

| 6 | Cabbage | room cooling, forced-air cooling, hydro-cooling | 24 | Radishes | ice cooling, hydro-cooling |

| 7 | Carrots (mature) | hydro-cooling, forced-air cooling | 25 | Raspberries | forced-air cooling |

| 8 | Carrots (young) | hydro-cooling, forced-air cooling | 26 | Rhubarb | hydro-cooling, forced-air cooling |

| 9 | Cauliflower | forced-air cooling | 27 | Rutabagas | ice cooling, hydro-cooling |

| 10 | Celery | forced-air cooling | 28 | Saskatoons (fresh use) | forced-air cooling |

| 11 | Chinese Vegetables | forced-air cooling | 29 | Spinach | forced-air cooling |

| 12 | Cucumbers | forced-air cooling, hydro-cooling | 30 | Squash (summer) | room cooling, forced-air cooling |

| 13 | Kohlrabi | forced-air cooling, ice cooling; hydro-cooling | 31 | Squash (winter) | room cooling, forced-air cooling |

| 14 | Leafy Greens | forced-air cooling | 32 | Strawberries | forced-air cooling |

| 15 | Leeks | ice cooling | 33 | Sweet Corn | ice cooling, hydro-cooling |

| 16 | Lettuce | forced-air cooling, vacuum cooling | 34 | Swiss Chard | forced-air cooling |

| 17 | Onions (green) | ice cooling | 35 | Tomatoes | room cooling |

| 18 | Parsnips | ice cooling, hydro-cooling | 36 | Zucchini | room cooling |

(Information gathered from USDA Handbook #66 and other sources).

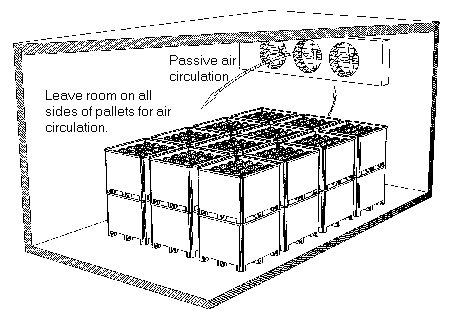

Room cooling is one method used for produce sensitive to free moisture or surface moisture. Because this type of cooling is slow, room cooling is only appropriate for very small amounts of produce or produce that does not deteriorate rapidly.

Produce is loaded into a refrigerated room or transportation truck. Cold air is circulated within the room and around the produce by the refrigeration fan/s. This is a slow method of pre-cooling because the cold air does not circulate readily through the produce (Figure A). This situation is particulary true for packaged produce. Room cooling systems are also used for the curing of produce such as winter squash.

Figure A. Room cooling is a slow method.

Forced air cooling is used mainly for bulk produce and palletized produce. It is the most versatile and widely used of all cooling methods. In forced air cooling, chilled air is forced to flow around each piece of produce. This close contact of chilled air with the produce results in rapid, even cooling throughout the mass of produce.

For piled bulk produce, such as carrots and potatoes, air ducts are used to distribute the chilled air through the produce. For palletized produce, pallets loaded with bulk or containerized produce are aligned with air ducts (plenums) that direct chilled air through them.

The air can be channeled to flow either horizontally or vertically. In a horizontal flow system, the air is forced to flow horizontally from one side of the pallet load to the other through holes in the sides of the pallet bin or containers (see Figure B). Only two sides that are opposite can be open in the pallet bin or containers. In stacking containers, the side holes must line up for the air to pass from one side of the stack to the other. In this system, the top and bottom of the pallet or containers must be sealed to prevent air from bypassing the produce.

In a vertical flow system, the air is forced to flow vertically from the bottom to the top of the pallet through holes in the bottom of the pallet, and containers if used, then out the top (see Figure C). In this system, the sides must be sealed to prevent the air from bypassing the produce. Also, if containers are used, the holes in the tops and bottoms of the containers must line up, so the air can travel vertically from one container to the next. This method is faster than room cooling because a flow of chilled air is in direct contact with the produce.

Figure B. Forced horizontal air flow.

Figure C. Forced vertical air flow.

In these systems, condensation on the produce can be minimized by a simple cover placed on top of the stack of containers, which prevents the entry of ambient air during handling.

To minimize moisture loss in room and forced air cooling, the evaporator of the refrigeration system should have as large a surface area as practical. Also, the evaporator should not be run at a temperature much below freezing as this practice causes undue drying of the air. Excessive air flow should also be avoided to minimize moisture loss.

A bed of chunk or cube ice can be used to provide cooling in place of a refrigeration system. The temperature of the air coming through a bed of melting ice will be in the range of 1 to 4 degrees centigrade and near 100 per cent humidity. See the section on "Ice, A Cold Source for Pre-cooling."

Room and forced air cooling systems are also used for the higher temperature curing of products such as onions, potatoes and squash, before cooling for extended storage.

Some market gardeners own a cold storage facility. Typically, these cold rooms are designed to remove heat from produce and other sources in 24 hours or maybe even longer. With increased refrigeration capacity and a system to force air through the produce, these facilities can also be used to rapidly pre-cool produce.

Mobile versions of forced air systems can be used in the field as an integral part of the harvest operations. Because produce can be loaded into the cooler as soon as it is harvested, cooling can be done within minutes of harvest. By minimizing the holding time before cooling, these systems can be very effective and competitive with other cooling systems that are currently considered as being fast.

Mobile systems can also serve as refrigerated shipping systems for local needs.

In hydrocooling, cold water is used to pre-cool produce. Produce may be immersed in a tank of circulating cold water or as in other techniques, cold water is sprinkled or sprayed over the produce. The equipment used for hydrocooling is often equipped with a water chiller.

This method of pre-cooling is faster than forced air cooling because water in direct contact with the produce has a higher heat removal capacity than air. If ice is available, it can be used to chill the water. See the section on "Ice, A Cold Source for Pre-cooling."

However, not all types of produce can be hydrocooled. Strawberries and cauliflower, for example, should not be cooled by this method because it results in rapid spoilage of the produce. Hydro-cooling requires particular attention to water quality and sanitation. Chemicals may be used to kill molds and bacteria in the water and on the produce.

In ice cooling, crushed or fine granular ice is used to cool the produce. The ice is either packed around produce in cartons or sacks, or it is made into a slurry with water and injected into waxed cartons packed with produce. The ice then fills the voids around the produce.

Ice cooling is faster than hydrocooling because contact with the produce is good, and ice has a higher heat removal capacity than water. It takes 144 BTUs of energy to melt 1 pound of ice. This amount will theoretically lower the temperature of 4 pounds of produce by at least 36 degrees Fahrenheit.

Ice can also provide cooling for extended periods. It is often a marketing requirement that there be ice remaining in the sacks or cartons of produce at the time it is received by the retailer. As in hydro-cooling, ice cooling requires particular attention to water quality and sanitation. See the section on "Ice, A Cold Source for Pre-cooling."

In vacuum cooling, containers of produce are put in a vacuum chamber. Air is drawn out of the chamber creating a high vacuum. Under the high vacuum, the boiling temperature of water is substantially lowered.

For example, water at the freezing point boils when the pressure is reduced to 0.08859 psi absolute. Normal atmospheric pressure is about 14 psi absolute. As a result, a small amount of water in the warm produce evaporates causing a corresponding lowering of the produce temperature. In some systems, the produce is misted with water to minimize weight loss.

Vacuum cooling is the fastest and most uniform method of pre-cooling because of the high amount of heat required for evaporating the water (about 1000 BTUs per pound of water evaporated). It is, however, one of the most expensive systems to set up.

Because vacuum cooling is a batch process, sufficient produce must be harvested to fill the vacuum cooler before cooling can begin. For the system to be effective, it is imperative that the produce not be held any longer than absolutely necessary after harvest and before cooling. As a result, harvesting and vacuum cooling systems must be very carefully matched.

Other sources of information: North Carolina State University at www.bae.ncsu.edu/programs/extension/publicat/postharv/index.html |

|