| | Advantages of portable windbreaks | Disadvantages of portable windbreaks | General design and requirements | Windbreak porosity | Vertical wall design | Slanted wall design | Mobility | References

Portable windbreak fencing for livestock shelter is an old idea that is gaining in popularity. A few producers were using these units decades ago. However, in recent years there has been a renewed interest in constructing and using mobile windbreak fences.

This publication lists advantages, disadvantages, features, and applications for portable windbreak fences. It includes pictures and designs of how producers and contractors are constructing units, with comments on their construction and effective use.

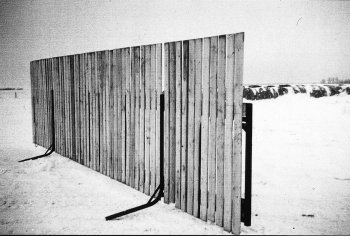

Figure 1. A portable windbreak fence shelters cattle in an open field.

Photo by Lloyd Thompson, Carnduff, SK.

Advantages of portable windbreaks

- Livestock can be wintered away from the yard-site or corrals for part or all of the winter season.

- The feeding and windbreak location can be moved on a regular basis, so the nutrients from manure and urine are spread over a large area. This reduces or eliminates the need for hauling and spreading manure with machinery.

- Manure can be concentrated on areas where soil fertility is lacking by placement of the windbreaks and feed.

- Livestock can be fed on virtually any parcel of land you choose, provided there is water or adequate snow available for a water source. Research has shown cattle using snow as a water source perform equal to cattle drinking water.

- The amount of hay hauling may be reduced. Where windbreaks and livestock can be moved to parcels of land adjacent to fields where bales are made, the bales can be picked and fed as needed.

- Fall and winter grazing practices such as stockpiling perennial forage, swath grazing, and crop residue grazing can be used on open parcels of land that do not have natural or other man-made shelter.

- Producers can winter livestock away from riparian areas that often have excellent natural shelter. Manure packs in riparian areas can potentially contaminate water sources.

- Livestock can be wintered on the same site for the entire winter season. In spring the portable windbreaks can be moved, allowing unhindered access for manure removal equipment without the risk of damage to the windbreak fence.

- Portable windbreaks can be sold separate from the land if a livestock operation is discontinued. Permanent windbreak fences are commonly sold with the land and the selling price does not always reflect the cost of construction.

- Portable windbreaks can be moved when snow accumulates, eliminating the need for snow removal.

- On calving grounds, disease buildup can be reduced when the location of the site is moved on a regular basis.

- Portable windbreaks can be moved to various pastures and used as temporary corrals for handling livestock.

- Feeding location can be away from the portable windbreak, and moved on a regular basis to avoid buildup of residue near the windbreak.

Disadvantages of portable windbreaks

- Require regular moving to gain many of the advantages mentioned above.

- Require regular moving in pastures and hayfields to avoid killing the perennial forage with excessive buildup of residue and manure.

- Require regular moving on cropland so tillage equipment does not plug with leftover feed and straw.

- The cost saving of reduced manure hauling may be offset by the increased cost of hauling feed to the field. Most producers have the equipment to haul feed to the field, but may have to hire contractors for manure hauling.

- On parcels of land that have significant amounts of natural shelter, portable windbreaks will be less effective at controlling livestock distribution.

- More expensive to build than a permanent windbreak fence.

- Can blow over in extreme winds.

- Bottom of frame can freeze to the soil or become lodged in snow and bedding material, making movement difficult.

General design and requirements

- Portable windbreaks need to be ruggedly built to withstand the stresses of moving and wind action. Steel frame units are probably the most durable.

- The bottom of the slab fence should have about one foot of ground clearance to prevent snow from building up directly underneath.

- The windbreak needs to be heavy with a broad base in order to counter the overturning force of the wind. Generally, the width of the base should be equal to or greater than the height of the fence.

- As a general rule, one foot of fence protects enough area for one cow. You need at least two units in a field so they can be placed at different angles to give protection from all wind directions.

Windbreak porosity

- The effectiveness of a windbreak is measured by the amount of wind reduction and the area in which the wind is reduced.

- Figure 2 shows the velocity reduction for different porosity fences, and the distance from the fence where the velocity is reduced.

Figure 2. Velocity reduction for different porosity fences.

- Optimum protection is obtained with a fence porosity of 25 to 33 per cent. The protected area will extend 8 to 10 times the height of the fence. To get 25 per cent porosity, space 6 inch boards 2 inches apart. To get 33 per cent porosity, space 6 inch boards 3 inches apart.

- There is no significant difference in wind protection if the boards are mounted vertically or horizontally.

- The force of wind tending to overturn a windbreak is made up of both pressure on the windward side, and suction on the leeward side. For that reason, a partially porous fence has to withstand the same amount of wind force as a solid fence. A force reduction from a reduced surface area is offset by increased suction when the wind penetrates the openings between slabs.

- Figure 3 shows wind turbulence about a solid fence, and snowdrift patterns about a porous fence. This demonstrates why solid walls should be avoided.

Figure 3. Snow drift patterns about solid and porous fences.

Vertical wall design

- Most units are constructed using a vertical wall.

- This design is easier to construct and requires less material in the frame.

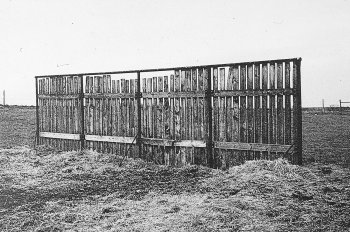

Figure 4 (top & bottom). This design requires the least amount of steel tubing in the frame. The horizontal wooden planks are not fastened to the frame, but are held in place when the slabs are nailed to the planks. The base is elevated with only four points touching the ground, reducing the possibility of freezing-in.

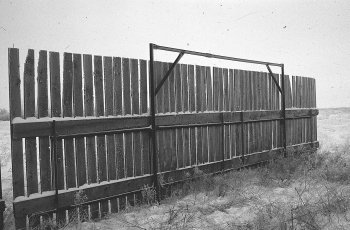

Figure 5. This design has steel tubing at the top of slab fence. The bottoms of the slabs should have one foot of ground clearance to avoid snow buildup at the base.

Figure 6. The steel tubing at the top of this fence allows you to insert the bucket tines of a front end loader with a grapple fork.

Figure 7. This sturdy unit requires relatively more steel tubing. It's base has a significant amount of contact with the soil surface, which increases the risk of it freezing-in. The bottoms of the slabs should be elevated one foot.

Figure 8 (top & bottom). An eight foot wing extension on a hinge at the end of the windbreak can be erected for opening and tying to the next portable windbreak.

Slanted wall design

- This design gives you the option of blocking off the backside so only younger stock have access to the area underneath the wall.

- If used in summer for shade, a slanted wall can shade more area from the sun.

- Require longer slabs to have the same effective height.

- Can be more difficult to construct.

Figure 9. This slanted wall design has a railing on the back so young animals can be bedded underneath. The cross braces are welded 18 inches high so they do not become embedded in the manure pack.

Figure 10. This slanted wall design unit overturned in 90 km/h wind gusts from the back side. For added safety, it requires extra weight or a wider base.

Mobility

An important feature for portable windbreak design is ease of movement with the power equipment available. This applies to moving within a field, but may also apply to long distance moving. Ease of movement within a field becomes especially important when weather conditions are adverse. Some units are designed so the operator does not have to leave the tractor seat. If movement cannot be done quickly and easily, the tendency will be to leave the portable windbreaks on the same place for extended periods, canceling some of the advantages of having them. Units are designed to lift and carry from the side or tow from an end.

A. Side lift

- Requires a tractor with a front end loader.

- Can be lifted and placed end to end to form a long fence.

- Less material needed in the frame because skids are eliminated.

- Can be built with an elevated frame so only four corners touch the ground. This eliminates the possibility of skids freezing in or becoming lodged in snow and manure.

- If snow accumulates on both sides, some snow removal may be required to gain access to a side.

- When lifted from the side to be moved from one field to another, gates must be wider than the length of the portable windbreak, or lift must be higher than the fence.

B. End tow

- Does not require a tractor with a front end loader.

- Requires more material in the frame for skids.

- Skids may freeze to the soil or become lodged in snow or manure.

- Can be moved through narrow gates.

- May not be as maneuverable or versatile as side lift fences.

C. Long distance moving

- Can load on a flatbed trailer.

- Can design with temporary or permanent hitches and wheels.

Figure 11. This unit has a temporary hitch and wheels that were added for long distance moving. Extensions are inserted into the pipe stubs at the base for greater base width when the unit is set down.

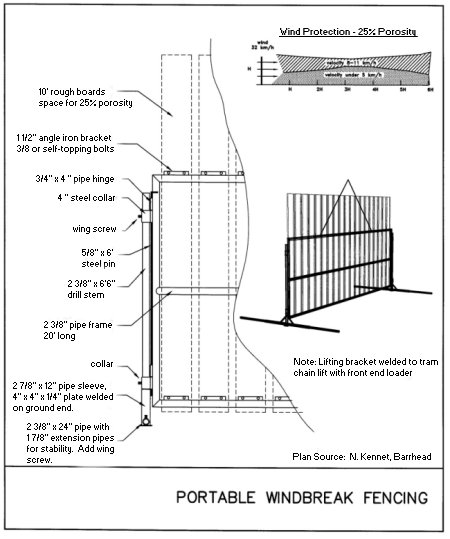

Figure 12. Plan for portable windbreak fence.

Most effective protection is achieved with fences of 25 to 33 per cent porosity. Effectiveness extrnds for 8 to 10 times the fence height to leeward.

1. slatted fence, 25 to 30 per cent porous

2. 2 x 6 rough rails at 24" to 32"

3. 6" pipe skids, sand fill for ballast

4. sway bracing every 24 feet

5. sub-frame of steel pipe

6. 4" steel pipe main post

7. adequate clearance, 12" to 16" typical

Figure 13. Alternative plan for portable fence sections.

Information prepared by

Lorne Klein

Grazing and Technology Program (GAPT)

Regina, Saskatchewan

Dennis Darby

Alberta Agriculture, Food and Rural Development - Lethbridge reviewed this Alberta Agriculture, Food and Rural Development edition and added Figure 13 and provided Figures 2, 3 and 12 to the original Saskatchewan edition.

References

Saskatchewan Agriculture and Food, March 1993, Porous Windbreak Fencing, Plan S-104.

Manitoba Agriculture, 1996, Portable Wind Fences: Good Tools for Management of Intensive Grazing.

Acknowledgements

The following businesses and individuals provided photographs and information: (1) Bob Bennet and Paul Cameron, Arcola SK; (2) EUR Ranches Ltd, Lake Francis MB; (3) Merle Heibert, Donavon SK; (4) K2 Elk Company, Weyburn SK; (5) Roger Meyer, Minton SK; (6) Olds College, Olds AB; (7) Paysen Livestock Equipment Inc, Central Butte SK; (8) R&H Feeds, Kelliher SK; (9) Ranchers' Welding Ltd, Cromer MB and (10) T4 Ranches, Carnduff SK.

This information was prepared by Lorne Klein under the Grazing and Pasture Technology Program (GAPT). GAPT is delivered by the Saskatchewan Stock Growers Association and Saskatchewan Agriculture and Food. It is funded by the Canada-Saskatchewan Agri-Food Innovation Agreement.

Source: Agdex 711-1. June 2002. |

|