| | Float | Intake | Intake pipe | Dugout aeration | Wet well

Research shows that water in the top four or five feet of a dugout is of higher quality than water at the bottom and edges. The reason for this difference in quality is that the algae and plants that grow in dugouts eventually die and decay at the bottom and edges, resulting in black, smelly water conditions.

Research also shows that although the addition of aeration to a dugout will improve dugout water quality, a float suspended water intake allows users to pull the best quality of water from the dugout.

Float suspended water intake systems have been successfully used in dugouts for the last 20 years. They have replaced the gravel type infiltration trenches that would fail from both sediment plugging and deteriorating water quality problems.

A floating water intake system allows water to be taken directly from the dugout through a pipe, thus avoiding the problems encountered with infiltration trenches.

These systems are also a better choice than the larger diameter solid pipe intakes that are placed near the dugout bottom. The larger intake pipes also allow small aquatic creatures, such as freshwater shrimp, to enter the wet well. These creatures tend to tend to plug up the intake screen on the pump, thus requiring the pump to be pulled to clean the screen. The floating intake is designed to both reduce inlet velocities through the screen area and be easily cleaned when required.

Floating intake systems are usually installed with a wet well that contains a submersible pump beside the dugout. However with jet pumps, the intake assembly hooks directly to the suction line, and a check valve is installed next to the pump. This system eliminates the need for a wet well.

Whatever the system chosen, it is recommended that intakes be planned and installed at the time of the dugout construction. This step avoids the extra challenge and cost of installing an intake system into a dugout full of water.

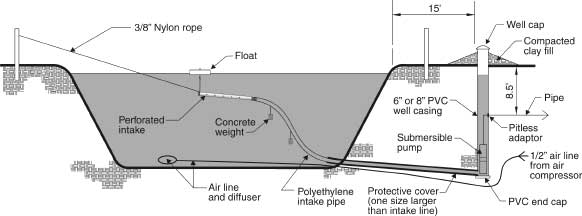

Figure 1 shows the components and installation of a typical submersible pump and intake system. The system components include the float, intake, intake pipe and wet well.

Figure 1. Submersible pump and intake system.

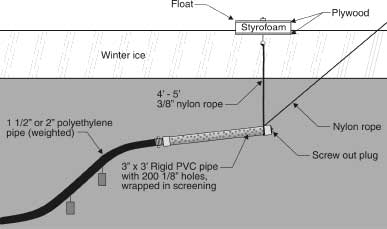

Float

The float is made from a two inch thick by two foot square piece of styrofoam sandwiched between two pieces of 1/2 inch thick marine plywood painted with a marine paint. The float is attached to the intake with a four to five foot length of nylon rope as shown in Figure 2. This length of rope is required to suspend the intake below the ice, so it does not freeze during the winter.

Intake

The intake shown in Figure 2 is made from a three foot length of three inch diameter rigid PVC plastic pipe. Since PVC pipe is heavier than water, it will drop the full length of the rope below the float.

During the winter, the float will freeze in the ice, but the intake will be below the ice. As water is used from the dugout, the ice and water level will continue to drop, but the intake will remain beneath the ice, protecting it from frost.

Drilling approximately 200, 1/8 inch diameter holes in rows along the pipe creates perforations that allow water into the pipe. It is recommended that screening be wrapped around the PVC pipe to prevent holes from being clogged with debris. The one pipe end is capped, and a plastic fitting is attached to the other end to connect the intake pipe.

Figure 2. Float suspended intake.

Intake pipe

The intake pipe is made of polyethylene plastic pipe with a 75 to 100 psi pressure rating. The intake pipe either supplies water from the dugout by gravity flow to a wet well (in the case of a submersible pumping system) or directly to a jet pump. The intake pipe should be placed inside another larger pipe at both the wet well and where it enters the dugout. This additional pipe will protect the intake pipe from possible damage or collapse during backfilling of the trench.

The polyethylene intake pipe is lighter than water and will require some small concrete weights to be attached to keep it from floating near the water surface and freezing. Another option is to use old steel cable and attach it to the pipe with nylon snap ties. This method provides a more consistent weight along the intake pipe.

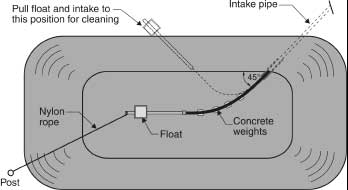

Another nylon rope may be attached to the intake to pull it to the shore for easy cleaning, as shown in Figure 3. The intake pipe should enter the dugout at a 45ø angle to reduce the risk of kinking the intake pipe when it is pulled to shore for cleaning.

The size of the intake pipe will depend on the required flow rates of the pumping system. The general rule of thumb for sizing the intake pipe is as follows:

Pipe Size

(inches) | Pipe Flow Rate

(gallons per minute) |

1 1/4 | up to 10 |

1 1/2 | up to 15 |

2 | up to 30 |

Figure 3. Plan view of float suspended intake.

Dugout aeration

The dugout aeration line should be installed in the same trench as the intake pipe, to protect it from freezing. Install the air diffuser away from the water intake, so bubbles will not be drawn into the water intake pipe. If bubbles are drawn in, air locks can be formed in the pipe, which will reduce or stop the water flow.

Wet well

A wet well is usually required beside the dugout to permit easy access to the pump. The water flows by gravity through the intake pipe and into the wet well as water is pumped from it. For many years, two to three foot diameter steel culverts were used for wet wells. Large diameter wells allow for settling of solids to take place.

However, recent monitoring of these installations has shown that the dissolved oxygen levels are much lower in the wet wells than in the dugout water. The reasons for this difference include the large water storage capacity of wet wells and the slow replenishment with fresh water. Wet wells, like gravel trenches, can develop problems such as hydrogen gas formation, lower pH, and a high concentration of nutrients. Therefore, six to eight inch diameter wet wells should be constructed instead.

More information can be obtained on farm dugouts by referring to the manual Quality Farm Dugouts - Agdex 716 (B01).

For further information, contact an Agricultural Water Specialist with Alberta Agriculture and Food at the following locations:

Lethbridge (403) 381-5846

Red Deer (403) 340-5324

Edmonton (780) 422-5000

Grande Prairie (780) 538-5606

Or at our website: www.agric.gov.ab.ca

Prepared by:

Technical Services Division

Source: Agdex 716 (B34). Revised June 2002. |

|