| | Marketing | Marketing options | Varieties | Floral induction and initiation | Field selection | Establishment | Fertilizing | Pest management | Harvesting | Post harvest management | Budgets and projections | References

Creeping red fescue seed production began in Canada in the 1930's. It developed into a dual purpose crop that provided revenue from the seed production in the summer and the grazing in the fall.

The seed was used for lawns, fairways, pastures and soil conservation purposes. Markets for creeping red fescue seed expanded as the need arose for a turf-forming grass to seed on airfields and around military bases.

Seed grown from the Boreal variety continues to be the main source of creeping red fescue seed produced in Canada. The Peace River region of Alberta and British Columbia is the largest producing area of creeping red fescue seed in the world. The 1991 Agriculture Canada Census reported 125,000 acres of creeping red fescue grown for seed in Canada and, of this, 99 per cent was grown in the Peace River region of Alberta and BC.

While creeping red fescue is a long-lived perennial, the seed production life of the stand is generally short, lasting only one to two years. On rare occasions, a third year may be harvested. Due to its creeping ability, creeping red fescue tends to sod in quickly. Seed head production is gradually suppressed as the stand ages and the number of vegetative tillers increases, making older stands unproductive.

Figure 1. Creeping red fescue field

Factsheet topics:

- Marketing

- Varieties

- Floral Induction and Initiation

- Field Selection

- Establishment

- Fertilizing

- Pest Management

- Harvesting

- Post Harvest Management

- Budgets and Projections

Marketing

Uses

Creeping red fescue seed is used mainly for turf, forage and reclamation purposes. The largest end use is for amenity purposes like lawns, parks, fairways and playgrounds. Most grass seed mixtures developed for these uses contain a certain percentage of creeping red fescue, Kentucky bluegrass or other creeping-rooted species. The majority of creeping red fescue seed grown in the Peace River region is exported to seed companies in the northern US although some seed is used domestically, and some certified seed is exported to Europe.

The demand for creeping red fescue seed is determined by the markets for turf mixes and the availability and price of other creeping rooted species such as Kentucky bluegrass. When the supply of grass seed, such as Kentucky bluegrass, is in short supply or high priced, companies will increase the percentage of creeping red fescue seed in turf mixtures.

Long term prices

The price of creeping red fescue seed is affected by the market demands of the US and Europe as well as the supply from the Peace River region, Denmark and the Pacific Northwest (USA). Denmark supplies Europe with certified seed. Sometimes this seed will compete with North American creeping red fescue seed, based on the supply of seed and its price.

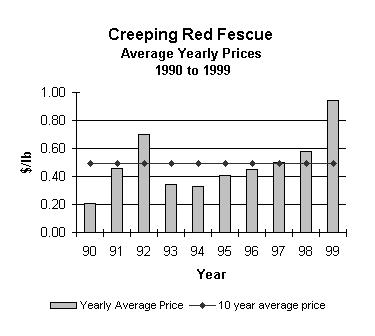

Figure 2 shows the average price of common creeping red fescue over the past 10 years. Creeping red fescue prices fluctuate greatly from year to year.

Figure 2. Ten-year average price of common creeping red fescue seed to the grower.

(Yearly average price based on monthly phone calls to various seed buyers and averaged for the year.)

Marketing Options

A producer marketing creeping red fescue has the option of selling into the cash market or to contract the crop. Companies will offer a number of specific alternatives within these two systems. The majority of fescue continues to be sold on the cash market where producers sell to the company they choose. Producers will also send samples of seed to the various companies to compare grade and dockage.

If producers are not happy with current prices, they have the option of storing seed until prices improve. If storing seed, consideration must be given to the risk of seed deterioration, cost of carrying inventories and cash flow needs.

Most companies will offer two contracting options: forward priced and production contracts. Forward pricing is a contract where the grower agrees to deliver a specified amount of seed to a seed company by a certain date. The seed company, in return, agrees to pay a specified price based on seed quality and grade.

A production contract is an agreement signed between the seed company and grower where the grower agrees to produce seed of a specific variety or from a specific land area. The seed is sold to the company at a specified price as long as the seed meets the quality standards outlined in the contract. The seed produced under contract is generally grown for certified production. It is very important for producers to fully understand the contract before signing.

Growing creeping red fescue with forward priced and production contracts reduces the risk of price volatility in the market as the grower knows the price they will receive. A rough estimate on yields and costs are also known, so the grower can estimate the amount of revenue that could be generated by the crop.

Certified versus common production

To grow Certified seed, Foundation seed must be planted. The grower must apply to the Canadian Seed Growers Association (CSGA) for field inspection during the year seed is harvested from the field. There are branch and inspection fees. Application deadlines for field inspections are in June.

It is important to keep the tags from the bags when purchasing the Foundation seed. The tags are needed to record the lot number on applications. There are regulations on previous crops grown in the field and isolation distances between certified and common fescue. Consult the CSGA guide "Pedigreed Forage Seed Production" for details and restrictions on growing certified grass seed.

Only about 10 to 20 per cent of the creeping red fescue grown in the Peace River region is certified seed; the rest is common. The majority of certified seed is sold into Europe, with only a small portion used in the North American market. The price difference to the grower between certified and common seed is generally $0.05/lb.

Common seed production occurs when growers purchase and plant certified or common seed, and there is no field inspection required. The majority of fescue seed sold into the US would be classified as Common #1 under the Canada Seed Act.

Quality

The price of creeping red fescue seed received by the grower is also determined by the quality of the seed produced. Quality is evaluated in terms of weed seed contamination, germination, purity and other crop types. Specific weeds can be problems depending on the destination and end use of the final product.

Some of the main weed contaminates that reduce the grade of creeping red fescue seed are quackgrass, wild oats and cleavers. Growers should make themselves aware of weeds that lead to grade reductions and discounts on the seed sold. This applies to seed produced for both domestic and foreign markets. Seed processors cannot clean out all types of weed seeds.

Varieties

The main variety of creeping red fescue grown in the Peace River region is Boreal or common seed grown from Boreal. Boreal seed is distributed and sold to growers and seed companies through the Canadian Forage Seed Project. If seed is to be purchased from the Canadian Forage Seed Project, applications must be submitted by December 31 of each year.

In addition to Boreal, an increasing number of proprietary creeping red fescue varieties are being grown for seed. These varieties are being bred by American, European and some Canadian companies for better turf characteristics than Boreal and are being used for a variety of uses in the market place.

These varieties are being grown under contract with a seed company where the seed produced is sold back to the company. It is important to access seed yield information on these proprietary varieties before entering into a contract.

Floral Induction and Initiation

Most perennial cool-season grasses go through several stages in their development relative to floral induction and initiation. Initially, after the seed germinates, there is a vegetative or juvenile stage during which the growing points of the grass develop into leaves and stems. These growing points grow vegetatively through the spring and summer. In the fall or early winter, there is a response to low temperatures (vernalization) and/or day length (short day). This response induces a tiller to become reproductive. This stage is called primary induction.

Primary induction of creeping red fescue is completed in late fall but only in those tillers that have had a full growing season of uninhibited growth. Many factors affect this induction process, including plant age, species, variety, nitrogen fertility, planting date, date of tiller formation, clipping or grazing, stage of plant development, plant spacing and temperature.

Secondary induction or floral initiation is the next stage. This stage is affected by timing and environmental requirements, which vary greatly among grass species. Many cool season grasses require a transition to warm temperatures and long days in the spring for floral initiation and further development of the seed head (Figure 3).

Figure 3. Floral initiation showing spikelets forming in late April.

Creeping red fescue has extreme inductive requirements for floral initiation. For flowering to occur in short days (less than 12 hours), the plants must be exposed to temperatures of 6 to 15°C for 12 to 20 weeks. However, variations will occur due to temperature and geographic origin of the cultivar. In creeping red fescue, floral initiation occurs shortly after spring thaw, which is earlier than for most other grass species.

Following floral initiation, the seed head develops. The developing seed head can be found at the base of a tiller as early as the end of April. The growth, and subsequent development, of the entire inflorescence and the spikelets is indeterminate, so some florets will be fully developed and others will be empty or sterile.

Anthesis occurs once the flowers have completely developed, and pollen is released from the anthers and carried by the wind. The release of pollen peaks around the middle of the day in fescues. The main factors affecting anthesis are temperature and relative humidity. High temperatures can cause blasting and poor seed set. Rainfall can have a negative affect on anthesis by causing earlier and shorter duration of anthesis during the day; however, wet weather can also extend the total time of anthesis.

Field Selection

Adaptation

Creeping red fescue can be grown on a wide range of soil types including clay, loam and sandy-loam soils when moisture is adequate. It will tend to perform best in areas that receive high levels of precipitation, especially when this precipitation is received in the fall and early spring. It tolerates soil acidity well and is somewhat tolerant to soil salinity.

Weeds

Creeping red fescue must be established in fields as free of perennial weeds and other volunteer grass crops as possible. Quack grass, foxtail barley, slender wheatgrass, volunteer forage grasses, Canada thistle, dandelions and volunteer clovers are examples of the perennial weeds that can cause problems in fescue production.

Most of these weeds can be cleaned up economically to acceptable levels by using pre-harvest applications of glyphosate in annual crops for several years prior to seeding fescue. Establishing creeping red fescue in a field with little or no perennial weed problems greatly reduces weed control difficulties once the crop is established.

Herbicide residues

Creeping red fescue seedlings can be seriously injured by residues of herbicides applied in previous years. Patchy emergence can often be observed when certain herbicides residues are present in the soil. Table 1 outlines herbicides that may be of concern when seeding creeping red fescue. The amount of herbicide residues will vary depending on the soil type, moisture, organic matter and pH.

Table 1. Creeping red fescue cropping restrictions for currently used herbicides (see Crop Protection Agdex 606-1)

Herbicides | Creeping Red Fescue Cropping Restrictions |

Ally

Amber

Assert

Accord

Escort

Muster

Muster Gold

Odyssey

Prism

Pursuit

Unity | Seedling creeping red fescue may be affected for one or more years after application. Conduct a field bioassay (a test strip grown to maturity) the year before planting creeping red fescue. The yield from the test strip should be compared to the yield from an adjacent untreated area. |

| Velpar | Do not attempt to seed a field bioassay before 24 months after the last Velpar application. |

Atrazine/Laddok

Primextra Light

Princep/Simazine | May cause severe injury to creeping red fescue one or more years after application. |

Edge

Fortress

Treflan/Rival/

Trifluralin/Bonanza

Heritage/Advance | Creeping red fescue should not be grown in rotation following a treated crop. High application rate caused by overlapping, improper calibration and non-uniform application may reduce fescue stands that follow in rotation. Drought conditions in the year of treatment may result in higher carryover into the next year. |

| Sencor | Creeping red fescue should not be grown for 24 months following application on irrigated alfalfa. |

| Banvel | Creeping red fescue may be affected if high rates of Banvel were used for perennial weed control the previous year. |

| Sundance/Anthem | Do not plant for at least 22 months following application. A field bioassay must be conducted the year prior to planting. |

Pedigreed requirements

If growing pedigreed seed (Breeder, Foundation and Certified), a number of requirements must be considered prior to selecting a field. The two main requirements are the previous crops grown and the isolation distance requirements from other fescue varieties. Growers are advised to refer to the Canadian Seed Growers Association handbook Regulations and Procedures for Pedigreed Seed Crop Production CSGA Circular 6-94 for details on specific requirements.

Establishment

The majority of creeping red fescue is underseeded with an annual crop. It is also possible to establish creeping red fescue without using an annual crop (cover crop). It is very important that the seed is placed into firm ground. This placement ensures that the fescue is not seeded too deep, helps keep the moisture at the soil surface, increases the rate of emergence and helps prevent the developing seedlings from running out of moisture. Seeding depth should not exceed 0.5 inch.

Underseeding fescue to annual crops

Annual crops used most often for underseeding fescue are canola and wheat. When under seeding to an annual crop, it is important to know the herbicide options available for both the annual crop and the under seeded fescue.

If swathing the cover crop, priority should be given to combining the crop as soon as possible. Early combining the swaths does not reduce the development of the fescue plants underneath. If a cereal crop is used and the straw is very heavy, consider baling up the straw to reduce the smothering effects of the straw. Chaff spreaders will also help reduce the swath effects.

The disadvantage of underseeding fescue with a cover crop is that the competition from the cover crop prevents the fescue plants from becoming large enough to produce a full seed crop in the following year. The year following seeding is then regarded as a clip crop where herbicides and mowing are used to keep weeds under control.

The clip year provides the fescue with an opportunity to grow and develop for one full year to ensure a seed crop is harvested the following year. Following the clip year, the stand is harvested for seed for either one or two years, depending on the stand density and the price forecast.

Straight seeding fescue

Creeping red fescue can be seeded successfully without a cover crop. Growers should be aware that creeping red fescue seedlings and plants are very slow to develop. The size and number of the plants in the fall are significant factors in determining yield potential the following year.

Due to its slow growth, it is very important to use practices that ensure the crop emerges quickly after seeding and has an opportunity to develop throughout the summer and fall with minimal competition from weeds. Seedbed preparation, seeding dates, weeds, and fertility are some factors the producer can manage to reduce the risk of losing two years of production before a seed crop is harvested.

When straight seeding creeping red fescue, avoid fields seeded to cereals the previous year. Volunteer cereals are competitive with developing seedlings and can sometimes be difficult to control. Prepare a firm, well-packed seedbed to ensure the seed can be placed shallow and evenly across the field.

Fescue is generally seeded with a drill in rows when straight seeded. One method that can be used is to seed into a stale seedbed. This method involves preparing the seedbed the previous fall or very early in the spring, which promotes the germination of some weed seeds and reduces soil moisture losses from excessive cultivation. The grass is then seeded one to two weeks after the last cultivation in the spring and sprayed with a glyphosate product prior to seedling emergence. This approach provides a cheap and effective method of controlling the first flush of weeds. There has also been some successful establishments using dormant seeding just before freeze-up.

Regardless of seeding method, fescue should be planted early in the spring and no later than June 15. Seeding early ensures the plant has ample time to develop throughout the year and can take advantage of early spring moisture for quick and even emergence. Late seeding results in reduced yields the following year.

There are many herbicide options for controlling broadleaf and grassy weeds in seedling fescue when seeded without a cover crop. Wick applicators and mowing can also be used in this situation. Field wick applicators can be used to apply a 20 per cent solution of glyphosate when the grassy weeds are taller than the fescue. Generally, two to three passes are made across the field in different directions. This is an economical and effective means of controlling annual grassy weeds. Mowing can be conducted two or three times during the summer to reduce weed competition.

It is best to use a combination of weed control techniques. Excessive weed material should be removed or chopped up in the fall. Do not leave swaths on the field as this coverage can kill fescue seedlings under the swath.

Fields that will be seeded to fescue should be soil tested prior to seeding to evaluate the soil nutrient status. Low rates of fertilizer can be placed with the seed when seeded in rows. Fescue seed is often added with phosphate fertilizer to provide a more uniform seeding of low rates. Immediate seeding (within 24 hours) is recommended although tests conducted in Dawson Creek by BCMAF indicated that fescue seed mixed with 11-55-0 fertilizer did not lose germination when tested 5 days after mixing.

Row spacing and seeding rates

The row spacing and seeding rates used will depend on the seeding equipment available, whether or not a companion crop is used, the seedbed condition, the soil type and the number of seed production years expected.

Fescue under seeded to an annual crop is generally broadcast at seeding rates between 1 to 4 lbs/acre. A higher seeding rate of 3 or 4 lbs/acre is sometimes used if a producer is targeting one crop and then removing the stand. Some producers find it easier to work up a field of fescue when only one crop is harvested. Most producers will seed at rates between 2 and 3 lbs/acre when under seeding fescue and planning on harvesting two seed crops.

When fescue is seeded without an annual crop and producers plan on harvesting two crops, the fescue is seeded between 1 and 3 lbs/acre on 12 to 14 inch row spacings. A few experienced growers will seed as low as 3/4 lbs/acre. Soil type and any tendency for surface compaction or crusting will also influence the seeding rate within the above range. The row spacing will be determined by the drill used. In many cases, every second drill run is blocked off.

If seeding without a cover crop and only harvesting one seed crop, a seeding rate of 3 to 5 lbs/acre on 7 inch rows has been used successfully. Using a high seeding rate and narrow row spacing helps ensure good uniform crop establishment and a seed crop in the following year (Figure 4). This strategy is often employed when the disease stem eyespot is a problem in the district. While a first year seed crop will become infected, the disease levels are not high enough for it to dramatically reduce seed yields.

Figure 4. Creeping red fescue seeded in rows.

Recent trials at Beaverlodge have shown that an initial plant density of 1 to 3 plants/ft² on rows no wider than 16 inches is optimum for 2 years of seed production when the stand is established without a cover crop. Initial densities of 1 to 3 plants/ft² on 8 inch rows or 1 to 5 plants/ft² on 16 inch rows provided optimum seed production for 2 years of seed production when the stand is established without a cover crop. A higher density of 5 to 10 plants/ft² is required when the goal is to harvest a single seed crop. The seed weight of creeping red fescue seed has been reported to be approximately 1.25 g/1,000 seeds.

Herbicides on seedling creeping red fescue

A number of products are registered for use on seedling stands of creeping red fescue, with seedling being defined as within three months of emergence. Herbicide application is usually recommended at the two to four leaf stage of seedling grasses. Herbicide selection is based on several criteria: the weeds present, effectiveness of the herbicide on these weeds, the tolerance of seedling creeping red fescue to the herbicide, the companion crop's tolerance and the herbicide's cost.

Developing fescue seedlings are very weak competitors; therefore, it is essential to keep competition from weeds to a minimum by eliminating the weeds early. Table 2 provides an outline of products that can be considered for application on seedling creeping red fescue. It also outlines several herbicides that have been shown to cause severe damage to creeping red fescue. Only herbicides that are registered can be recommended for use.

Table 2. Herbicides on seedling creeping red fescue (2-4 leaf stage).

Fertilizing

Method and timing of application

Creeping red fescue is traditionally fertilized with nitrogen in the fall of the year prior to the production of a seed crop. Early studies conducted at Beaverlodge showed that fertilizer nutrients are more effective when made available to the crop very early in the spring, as floral initiation occurs soon after spring thaw.

By applying fertilizer in the fall, the producer ensures that the nutrients will be available to the plant in early spring. In addition, spring weather conditions can sometimes delay spring fertilizer applications on fescue stands. Fertilizer has historically been cheaper in the fall as compared to the spring as well.

Recent research trials conducted at Beaverlodge compared the effects of three different dates of nitrogen application and three different methods of application on creeping red fescue seed yields. The rate used in the trial was 60 lbs/acre of nitrogen. The application times compared were fall (just prior to soil freeze up in early-to-mid October), early spring (after snow melt but before crop green-up in late March to mid-April) and late spring (mid-April to early-May). The methods of nitrogen application included surface broadcast with 34-0-0, a foliar/soil spray of 28-0-0 solution and soil-injected 28-0-0 solution.

Six trials were conducted over a five-year period. There was no significant difference in yield among the times and methods of application (Table 3). The results support earlier fertilizer recommendations but also show that producers have considerable flexibility in when and how nitrogen fertilizer is applied. It seems fall applications or very early spring applications will provide more consistent yields from year to year.

Table 3. Effects of method and time of nitrogen application on creeping red fescue seed yields.

Rates of nitrogen fertilizer

Very little recent work exists on rates of nitrogen application on creeping red fescue seed stands. Rates applied by producers vary from 30 to 80 lbs/acre of nitrogen, although the most common rate used would be 60 lbs/acre of nitrogen. The rate of nitrogen applied will depend on the degree of sodding evident, the soil fertility status, soil moisture conditions, the size of the previous crop, fertilizer prices and expected seed price levels. Generally, lower rates of nitrogen are used on older sodded stands.

Historically, the majority of fescue fields received only nitrogen. There has been a recent trend by producers to use more balanced blends that include phosphorous, potassium and sulphur. Soil tests will help determine what nutrients are necessary and at what rates they should be applied.

Form of nitrogen application

Care must be taken in deciding what form of nitrogen to use since most of the fertilizer applied to creeping red fescue stands is broadcast. Ammonium nitrate (34-0-0) is recommended over urea (46-0-0) for broadcasting since urea has greater potential for losses through gassing off (volatilization).

The risk of nitrogen losses when using urea are greatest with soils that are warm, high in pH and sandy. Urea losses can also be high when there are high winds, high levels of surface residues, wet soil surfaces and soil temperatures above 10°C.

Conditions favorable to urea fertilizer use are a dry, unfrozen soil surface with rainfall or snow occurring shortly after application. A 0.5 inch of rainfall is required to move urea into the soil and prevent losses to the air. Some producers will apply urea on top of several inches of snow when the ground is not frozen and the snow is expected to melt.

Fertilizer should not be applied on top of frozen ground covered with several inches of snow as this would prevent the fertilizer from moving into the soil, making it susceptible to runoff in the spring.

Pest Management

Weed control on established stands

Producing a seed crop free of weed seeds is a function of several factors: how clean the field was of perennial weeds prior to seeding, stand establishment, row spacing, fertility, combine settings and the choice of in-crop herbicides. Wild oat, quackgrass, Canada thistle, narrow-leaved hawk's-beard, cleaver, dandelion and volunteer clover are common problem weeds found in established stands of creeping red fescue.

A number of herbicide options are available to use on established creeping red fescue, but attention must be given to herbicide rate and the crop stage at application. Herbicide selection will depend on the weeds present, tolerance of the fescue, available tank mixes, stage of the fescue, cost and rotation of herbicide groups. Table 4 provides an outline of products that can be considered for spring application on established creeping red fescue prior to the shot blade stage. Table 4 also outlines several herbicides that have been shown to cause severe damage to creeping red fescue.

Table 4. Herbicides applied in the spring on established creeping red fescue.

Research trials carried out at the Agriculture and Agri-Food Canada Research Station at Beaverlodge have shown that care is advised when applying herbicides on established stands. Table 5 shows the results from applications of 2,4-D made at several different growth stages of creeping red fescue.

Table 5. Tolerance of established creeping red fescue to 2,4-D ester (600 LV ester) applied at several different growth stages.

Experiments in Control of Weeds in Grass Seed Crops, 1971-1996, Darwent and Drabble.

2,4-D applied in September of the year of establishment reduced seed yields the following year by 25 to 50 per cent. Therefore, 2,4-D should not be applied to creeping red fescue in the fall of the year of seeding. 2,4-D application in the fall is safe only after the first seed crop is harvested.

Tables 6 and 7 show results from a trial conducted to evaluate foxtail barley and volunteer bromegrass control with graminicides tank mixed with and without broadleaf herbicides at six sites. The trial also evaluated dandelion and volunteer alsike clover control.

The study showed that Poast Ultra applied at 360 ml/acre and Venture applied at either 200 or 400 g/acre reduced the heading of foxtail barley and volunteer bromegrass growing in creeping red fescue seed fields. Ally tank mixed with either Poast Ultra or Venture did not result in loss of efficacy in grassy or broadleaf weed control. Tank mixing Venture or Poast Ultra with 2,4-D either alone or with Banvel reduced grassy weed control, decreasing the quality of the seed produced as a result. The results indicate that care must be taken when selecting herbicides to tank mix.

Of the broadleaf herbicides tested, Ally provided the most consistent control of volunteer alsike clover and dandelions. (Table 7). 2,4-D alone provided unsatisfactory control of alsike clover and dandelion. Tank mixing graminicides with the broadleaf herbicides did not reduce broadleaf weed control.

Table 6. Effects of herbicide applications and tank mixes on control of foxtail barley and smooth bromegrass applied in the spring on established creeping red fescue.

Herbicide treatment* | Rate | Per cent frequency of 100% reduction in heading |

|

ml or g/acre

| Foxtail barley | Volunteer brome |

Average of all

sites | Range among

sites | Average of all

sites | Range among

sites |

| Poast Ultra | 180 | 56 | 25 - 100 | 62 | 50 - 75 |

| Poast Ultra | 360 | 88 | 75 - 100 | 100 | - |

| Poast Ultra + Ally | 360 + 3 | 94 | 75 - 100 | 87 | 75 - 100 |

| Poast Ultra + Banvel + 2,4-D | 360 + 240 + 460 | 75 | 25 - 100 | 75 | 50 - 100 |

| Poast Ultra + 2,4-D | 360 + 460 | 50 | 25 - 75 | 100 | - |

| Venture 25DG | 200 | 89 | 75 - 100 | 75 | - |

| Venture 25DG | 400 | 94 | 75 - 100 | 100 | - |

| Venture 25DG + Ally | 400 + 3 | 94 | 75 - 100 | 100 | - |

| Venture 25DG + Banvel + 2,4-D | 400 + 240 + 460 | 86 | 75 - 100 | 87 | 75 - 100 |

| Venture 25DG + 2,4-D | 400 + 460 | 69 | 25 - 100 | 87 | 75 - 100 |

* Surfactants used according to registration

Experiments in Control of Weeds in Grass Seed Crops, 1971-1996, Darwent and Drabble.

Table 7. Effect of herbicides for control of dandelions and volunteer alsike clover applied in the spring on established creeping red fescue.

Herbicide treatment* | Rate | Per cent frequency of > 80%

Dandelion control | Per cent frequency of > 90%

Alsike control |

| ml or g/acre | Mean of all

sites | Range among

sites | Mean of all

sites | Range among

sites |

| Poast Ultra + Ally | 360 + 3 | 94 | 75 - 100 | 96 | - |

| Poast Ultra + Banvel + 2,4-D | 360 + 240 + 460 | 62 | 25 - 100 | 100 | - |

| Poast Ultra + 2,4-D | 360 + 460 | 0 | - | 0 | - |

| Venture 25DG + Ally | 400 + 3 | 100 | - | - | 75 - 100 |

| Venture 25DG + Banvel + 2,4-D | 400 + 240 + 460 | 71 | 25 - 100 | 79 | 50 - 100 |

| Venture 25DG + 2,4-D | 400 + 460 | 6 | 0 - 25 | 0 | - |

| Ally | 3 | 94 | 75 - 100 | 96 | 75 - 100 |

| Banvel + 2,4-D | 240 + 460 | 25 | 0 - 75 | 63 | 25 - 100 |

| 2,4-D | 460 | 6 | 0 - 25 | 0 | - |

* Surfactants used according to registration.

Experiments in Control of Weeds in Grass Seed Crops, 1971-1996, Darwent and Drabble.

The only treatment that tended to yield less than the check was Banvel+2,4-D treatments. All other treatments yielded similar to the check (Table 8).

Table 8. Seed yields of creeping red fescue following spring applications of herbicides (6 sites).

Herbicide Treatment* | Rate | Seed Yields |

| ml or g/acre | kg/ha |

| Check |  | 904 |

| Poast Ultra | 180 | 904 |

| Poast Ultra | 360 | 969 |

| Poast Ultra + Ally | 360 + 3 | 911 |

Poast Ultra +

Banvel + 2,4-D | 360+

240 + 460 | 714 |

|  |  |

| Poast Ultra + 2,4-D | 360 + 460 | 824 |

| Venture 25DG | 200 | 935 |

| Venture 25DG | 400 | 853 |

| Venture 25DG + Ally | 400 + 3 | 904 |

Venture 25DG +

Banvel + 2,4-D | 400 +

240 + 460 | 679 |

|  |  |

| Venture 25DG + 2,4-D | 400 + 460 | 891 |

| Ally | 3 | 933 |

| Banvel + 2,4-D | 240 + 460 | 780 |

| 2,4-D | 460 | 860 |

Experiments in Control of Weeds in Grass Seed Crops, 1971-1996, Darwent and Drabble.

Fall spraying of established creeping red fescue fields (after the first crop is harvested) with 2,4-D+ Banvel is an effective method for controlling winter annual weeds, such as narrow-leaved hawk's-beard and perennial weeds like clover and dandelion. It is important to remove volunteer clovers from creeping red fescue seed fields as early as possible because clover is very competitive and will reduce fescue seed yields.

Diseases

Disease problems are a major concern in creeping red fescue seed production. Many grass diseases affect creeping red fescue, but the most important disease is stem eyespot (Didymella festucae). Stem eyespot is a fungal disease that attacks the stem, cutting off the flow of nutrients to the fescue seed head.

Stem eyespot builds up gradually in the field. It can have devastating effects on fescue seed yields by the second or third seed year, reducing yields by 50 per cent or more. Removing the aftermath is critical for limiting the increase of stem eyespot disease as well as for inducing tillering in subsequent crops.

Other control options include stand rejuvenation, fall fertilization and burning prior to rejuvenation. Another option that has been used by producers is to establish a stand at high seeding rates with the goal of harvesting only one seed crop. The disease may show up in the crop but not as severe as in older stands. The disease does not girdle the stem as severely in the first year of seed production.

Another important disease in creeping red fescue fields is snow mold. Removing the harvest aftermath and ensuring adequate soil fertility are the most effective steps to limiting damage.

Insects

Silvertop can result in economic losses in fescue seed production. Estimated losses due to silvertop range from 12 to 14 per cent in Canada but have been recorded at 95 per cent in the United States (Figure 5).

Figure 5. Silvertop in creeping red fescue.

Silvertop or silvertip is characterized by bleaching or whitening of the terminal portion of the stem beginning from the last stem node and extending to the tip of the seed head. Bleaching occurs soon after emergence from the boot. The affected stems break easily or can be pulled from the leaf sheath. There is either no seed or sterile seed in the seed head.

Variables associated with silvertop incidence in fescue seed fields are the stand's age and the species of grass grown for seed. The causal agent of silvertop has not been identified yet. A fungus has been identified in silvertop stems, but a range of insects and mites have also been shown to be associated with affected stems. Research on silvertop is currently being conducted in the Peace Region.

True bugs including Capsus cinctus (black grass bug), Labops, Stenodema vicina (green plant bug), S. trispinosa, and Litomiris debilis are present in creeping red fescue seed fields in the British Columbia Peace Region, which has developed silvertop. Several species of plant bugs, leafhoppers and spittlebugs are associated with stands that developed silvertop in grass stands grown in Alberta, Saskatchewan and Oregon. Thrips have also been collected in fescue fields that developed silvertop in Alberta.

Other preliminary work suggests that applications of insecticide reduce silvertop. This finding implicates insects and mites as causal agents in the development of silvertop in fescue seed production. The insect punctures holes through the leaf sheath above the last node and damages the tissue in the main stem.

Insecticides will have no impact on silvertop levels once all the heads have emerged. Insecticides must be applied prior to or at the shot blade stage to be effective. If high levels of silvertop are evident (greater than 10 per cent) in a fescue field, the field should be monitored closely the following year, and control measures may need to be implemented. Insecticide application may be necessary although this approach will also depend on the value of the crop. Removing residue from the field and close mowing after harvest can help reduce disease levels in the following year.

Leafhoppers are another insect pest that can occasionally cause severe damage to fescue. Large populations can develop quickly. If present just after heading, leafhoppers can cause heavy yield losses by feeding on succulent emerging fescue seed heads. The damage caused is often mistaken for silvertop. While silvertop damage to affected seed heads is complete, the head damage caused by leafhoppers is often partial. Control may be considered if emerging seed heads show signs of damage, and large clouds of leafhoppers rise up when the field is walked through.

Harvesting

The time between pollination and the start of harvest is 20 to 30 days. Swathing in the Peace Region generally begins between the third and fourth week of July. This timing will vary depending on environmental conditions. The majority of creeping red fescue is swathed prior to combining. The stage of fescue at the time of swathing and the combine settings used will have a significant effect on the quality and yield of the crop.

Time of swathing

Fescue plants mature unevenly across the field. The decision on when to swath must be based on the stage the majority of the plants are at in the field. As fescue fields mature, they will change in appearance from green to red to brown.

It is important to be patient when deciding to swath as cutting fescue too early will result in reduced yield and decreased seed quality. Fescue does not shatter too excessively, and swathing in evenings or at night will reduce the amount of seed shattering. Consideration should be given to the number of acres to be swathed and the weather conditions. Fescue heads will generally ripen from the top down (Figure 6).

Figure 6. Creeping red fescue ready to swath.

Moisture testing can assist the producer in determining when to swath. Swathing of creeping red fescue can begin when the seed head moisture content is 35 per cent and a few green heads remain. To conduct a moisture test, collect a representative sample of heads from the field, usually in mid-afternoon. The entire head should be clipped off just below the lowest branch.

The sample must then be weighed and dried down until all the moisture is removed. Drying can be done by using a conventional home oven set at 180°F (82°C) for 4 or more hours. A microwave oven can also be used. If using a microwave oven, place the sample in the oven along with a cup of water. This method will prevent the sample from burning and causing damage to the oven. Dry the sample for five minutes, weigh it and then dry the sample for an additional two to three minutes. Weigh the sample again and continue with this process until the weight remains constant.

To figure out per cent moisture, use the following formula: wet weight - dry weight/wet weight x 100. An accurate scale must be used when weighing samples.

Producers will use other methods to determine when to swath. The crop is considered ready to harvest when 75 per cent of the seed heads have seed at the medium to hard dough stage (moderate to hard pressure with a thumbnail will dent the seed and leave an imprint).

Another method involves taking seeds from heads and rubbing them in the palm of your hand with a lot of pressure. If there is a high level of pink color stain left on your hand, it is still too early to begin swathing. If there is a slight stain left, the fescue is ready to be swathed.

Another method used by producers involves taking a handful of fescue stems and striking them against the palm of the hand. If the seed is just beginning to shell out, then swathing can begin. This method is used but is not generally the most accurate method of determining when to swath.

Timing of swathing is critical. Swathing too early results in many empty seeds, while swathing too late can result in shattering losses. In both cases, yields are reduced.

The first seeds lost are generally the heaviest and have the best germination. The amount of material in the swath will also have an affect on how the seed cures. Swaths with higher levels of material will help the seed cure if the fescue was cut at an early stage and will help prevent the seed from shriveling up and drying too quickly.

In hot dry weather, it may not be possible to swath large fields fast enough to avoid excess shattering. Fescue that is ripe and prone to shattering should be swathed during the evening and night to minimize losses.

Combining

Combining is usually conducted on a swathed crop. Straight combining is seldom used in fescue seed production because of problems with shattering losses, uneven maturity and weed problems.

A properly adjusted combine is essential to produce maximum yields and high seed quality. Combine settings can also be used to help improve the chances of removing unwanted weed seeds such as wild oat, quackgrass and cleavers at the seed cleaning plant. Proper combine settings will vary from day to day, as well as during the day, depending on weather and moisture conditions of the swaths and seed.

When combining fescue, the cylinder speed should be set as low as possible with the concave open. Cylinder speeds of around 400 to 600 rpm are used when the crop is dry, but may be around 800 rpm when conditions make thrashing the seed tougher. Too high, a cylinder speed will result in cracked seed.

The clearance between the cylinder and concave should be adjusted to the point where hard rubbing action occurs, but not to the point of peeling the seed coat. If there is no evidence of doubles in the sample, the seed is being over thrashed. There should generally be 5 to 8 per cent doubles in a sample. Minimum air should be applied to keep the material flowing over the sieves without coming off the back in bunches. Combining is a slow process as it takes time for the seed to settle out from the forage material on the walkers.

Fescue dockage is generally around 20 per cent. Lower dockage may be a sign of over thrashing.

The importance of proper combine adjustment to ensure minimal seed losses and high quality seed cannot be overstated. Samples during combing should be taken to seed companies or elevators to ensure a proper job of combining is being done.

Fescue should be stored at 12.5 per cent moisture or lower. Fescue can been harvested at up to 16 to 17 per cent moisture, but aeration will be required to reduce the moisture content.

Post Harvest Management

Removing residue

Crop aftermath is removed to improve field sanitation for reduced disease and insect problems and for increased seed yield in the subsequent crop. The straw should be baled and removed immediately after combining. This technique will remove much of the source of stem eyestop infection. It also provides a better environment for tillers to develop for succeeding seed crops.

Feed value of straw bales

The feed value of creeping red fescue straw compared with cereal and other grass seed straw is shown in Table 8. The feed value of creeping red fescue straw is generally better than most cereal straws, but lower than hay or silage.

Creeping red fescue straw can be used for feed or bedding. If used for feed, the straw should not be considered a complete feed for wintering beef cows and should be tested for feed quality and supplemented with other feeds. If used in this manner, the cows nutritional requirements can be met while maximizing the use of low quality roughage.

This approach usually means supplementing rations with high protein feed. Check feeding restrictions from herbicides that were applied to the fescue.

Some creeping red fescue varieties may contain endophytes. High levels of endophytes can produce toxins that are harmful to livestock. Talk to seed companies or local extension personnel if/or whether a particular variety may be infected or not.

Table 9. Nutritional value comparison of cereal and grass seed straws.

Straw | #

Samples | Protein

% | Acid

Detergent

Fibre % | Digestible

Energy

Mcal/kg | Total

Digestible

Nutrients % |

Barley

6 row | 282 | 5.4 | 44.4 | 2.25 | 51.1 |

Barley

2 row | 70 | 5.1 | 44 | 2.38 | 54.1 |

Timothy | 16 | 3.8 | 41.9 | 2.28 | 51.9 |

Oats | 215 | 4.8 | 44 | 2.26 | 51.4 |

Tall fescue | 11 | 7.4 | 39.9 | 2.45 | 55.1 |

Creeping

red fescue | 5 | 5.1 | 44.7 | 2.23 | 49.9 |

Mowing

To increase seed yield, a flail or rotary mower is used to cut the aftermath. There has not been definitive research to determine the best time or height at which to clip the fescue aftermath.

Current knowledge of the physiology of seed production, observation and practice would suggest it should be cut right after seed harvest. If the clipping is done early, then more new growing points should be stimulated. This method will allow the new growing points sufficient time to develop so that floral induction takes place in the late autumn. It is suggested that fescue should not be clipped lower than 3 inches (Figure 7).

Figure 7. Creeping red fescue clipped to the desired height.

There is only one situation where it was observed that clipping the field damaged seed production, and that is when there was a severe and prolonged drought in the fall, which carried through to freezeup. In this case, the new growing points (new shoots) were reduced instead of increased.

Burning

Burning following the seed harvest or in the spring, will significantly reduce or eliminate seed yields the following year. Following seed harvest in the Peace Region, there is not enough time to burn and then have the crop recover before winter. Following the final seed harvest in a cycle and before rejuvenation, fire has been used to assist in controlling both stem eyespot and insects.

Grazing

Grazing of creeping red fescue can maintain or even increase seed production. In some cases, grazing allows a third year seed harvest. It is preferable for grazing to be sufficiently heavy to obtain even aftermath removal. The cattle or sheep should be removed when a stubble height of 2 to 3 inches remains. Severe overgrazing can reduce fescue yields.

Trials conducted at the Agriculture and Agri-Food Canada Research Station at Beaverlodge showed that yearling cattle grazing creeping red fescue aftermath in the fall could gain 2.25 to 2.5 lbs/day. The same aftermath cut and baled and fed in a dry lot resulted in gains of 1.5 lbs/day. Fall grazing from September to freeze-up at moderate stocking rates (1.5 animal units/acre) reduced seed yields by 8 per cent the following year. High intensity grazing (2.5 animal units/acre) reduced seed yields by 16 per cent. In one trial, light grazing on lush stands did not result in reduced seed yield. Spring grazing is not recommended.

Rejuvenation

The purpose of rejuvenation is to reduce the plant population by disturbing or reversing the sod forming characteristic of fescue, so new growth develops from some of the remaining crowns or rhizomes. Rejuvenation is usually required following two seed harvests. Fire is sometimes used before rejuvenation to reduce disease and insect problems.

The most common method for rejuvenation is to use a moldboard plow in the spring, prior to June 15. The field is then rolled shortly after plowing, followed by discing or floating (Figure 8). The fescue regrows in rows between the furrows. A seed crop is produced the following year. In a field of certified creeping red fescue, one rejuvenation cycle is possible, and the seed produced will still maintain certified status.

Figure 8. Rejuvenation of creeping red fescue using plowing

Another implement used is heavy duty scallop-bladed discs, either tandem or offset. Further discing, rolling and floating is required to obtain a smooth field (Figure 9 and 10).

Figure 9. Rollers.

Figure 10. Rolling shortly after plowing creeping red fescue.

In an effort to reduce cost, chemical rejuvenation using glyphosate to spray out strips leaving rows untouched has been tried but not successfully. The remaining unsprayed portions are still sod-bound, and the margin between the sprayed and unsprayed area is not stimulated to produce new growth to the same extent as occurs with cultivation.

Two types of moldboard plows are commonly used in the Peace region:

- General purpose bottoms - for many years, 14 inch bottoms were preferred, but as these became less available and tractor H.P. increased, 16 inch and then 18 inch bottoms were used. Discing and floating is required to smooth the field prior to spraying, swathing and combining.

- Sod bottoms - these bottoms turn the furrow completely, without it breaking, leaving the field smoother and requiring less follow-up work to prepare a smooth field as compared to the general purpose bottom plows. The field is not disced but is only rolled and floated. Fescue growers using this method had rollers long before they became common for smoothing pea fields. Plows such as the Kverneland or John Deere with Kverneland bottoms are typically used.

Floats are made from a range of materials: heavy wood planks lapped like clapboard siding, old cat rails spread apart with a log or steel pipe, or pieces cut out of old railway track lengths.

In the past, a practice of fall or early spring plowing and seeding flax was common, with the fescue recovering under the flax. Fall plowing had a higher risk due to variable moisture conditions and the severity of winter temperatures prior to a protective covering of snow.

In more recent years, this practice has been used by some producers growing canola. The same risks exist. While canola is more competitive than flax, the typically higher nitrogen application with canola can allow for more vigorous development of the surviving plants. Generally, the best results are obtained by not involving another crop in the rejuvenation process.

Budgets and Projections

Estimated cost and returns budget for creeping red fescue - under seeded to canola

Introduction - This budget estimates the direct income and expenses over the life of a Creeping Red Fescue stand, on one acre of Creeping Red Fescue under seeded to canola. These numbers are intended to assist producers in evaluating the basic financial requirements over this period. The Contribution Margin must provide funds for interest, overhead and other indirect expenses as well as a return for living, loan repayment and investment. A total farm financial analysis should be completed in order to determine the impact of this enterprise on the total farm business.

Assumptions - The following assumptions and timing for field operations were assumed in deriving these costs:

| Year 1 - Establishment & Under seeding to Canola |

| Prev. fall | 1 | Pre-harvest glyphosate for perennial weed control |

| May | 2 | HD and a light duty cultivation |

| 3 | Apply anhydrous |

| 4 | Seed canola/fescue |

|  | (with grass seed attachment on drill) |

| 5 | Harrow pack |

| June | 6 | Spray Poast Ultra + Lontrel |

| Aug/Sept | 7 | Swath Canola |

| 8 | Combine/truck/augers |

|  |  |

| Year 2 - Clip Year |

| June | 1 | Spray Banvel + 2,4-D |

| 2 | Mow |

| Sept | 3 | Mow |

| Oct | 4 | Broadcast fertilizer |

|  |  |

| Year 3 - Production |

| May | 1 | Spray Ally +Venture |

| July | 2 | Swath |

| Aug | 3 | Combine/truck/augers |

| 4 | Bale (zero net cost)1 |

| Sept | 5 | Mow |

| Oct | 6 | Broadcast fertilizer |

| 1Assumption that returns for baling aftermath will cover costs |

|  |  |

|  |  |

| Year 4 - Production |

| May | 1 | Spray Refine Extra + Assure |

| July | 2 | Swath |

| Aug | 3 | Combine/truck/augers |

| 4 | Bale (zero net cost) |

|  |  |

| Year 5 - Rejuvenate (field is either returned to annual crops or rejuvenated) |

| May | 1 | Plow |

| 2 | Roll |

| 3 | Float |

| Aug | 4 | Spray Banvel + 2,4-D |

| 5 | Mow |

| Oct | 6 | Broadcast fertilizer |

|  |  |

| Year 6 - Production |

| May | 1 | Spray Ally + Venture |

| July | 2 | Swath |

| Aug | 3 | Combine/truck/augers |

| 4 | Bale (zero net cost) |

| Sept | 5 | Mow |

| Oct | 6 | Broadcast fertilizer |

|  |  |

| Year 7 - Production |

| May | 1 | Spray Refine Extra + Assure |

| July | 2 | Swath |

| Aug | 3 | Combine/truck/augers |

| 4 | Bale (zero net cost) |

| Sept | 5 | Plow |

Price and production sensitivity - The following table shows the impact on Contribution Margin in the established stand (year 6) resulting from a change in projected market returns and yields.

Price | Yields: lbs. per acre |

$/lb | 200 | 400 | 600 | 800 |

0.20 | -7.30 | 32.70 | 72.70 | 112.70 |

0.30 | 12.70 | 72.70 | 132.70 | 192.70 |

0.40 | 32.70 | 112.70 | 192.70 | 272.70 |

0.50 | 52.70 | 152.70 | 252.70 | 352.70 |

0.60 | 72.70 | 192.70 | 312.70 | 432.70 |

0.70 | 92.70 | 232.70 | 372.70 | 512.70 |

0.80 | 112.70 | 272.70 | 432.70 | 592.70 |

Certified seed usually commands a $.05/lb premium over common, but overall price levels depend on the American and European grass seed market.

Per Acre Costs & Returns for Creeping Red Fescue Under Seeded to Canola Years of Production - 7

Click on PDF file for values PDF File

This information is provided as a guideline only. Projected yields indicate about average production. An individual crop plan should be developed by each producer. Planning forms may be obtained from your local Government Agriculture Office in British Columbia or Alberta.

Costs & Returns for Straight Seeded Creeping Red Fescue

Introduction - This budget estimates the direct income and expenses over the life of a Creeping Red Fescue stand, on one acre of Creeping Red Fescue. These numbers are only intended to assist producers in evaluating the basic financial requirements over this period. The Contribution Margin must provide funds for interest, overhead and other indirect expenses as well as a return for living, loan repayment and investment. A total farm financial analysis should be completed in order to determine the impact of this enterprise on the total farm business.

Assumptions - The following assumptions for field operations were assumed in deriving these costs:

| Year 1 - Establishment |

| Prev. fall | 1 | Pre-harvest glyphosate for perennial weed control |

| May | 2 | HD and a light duty cultivation |

| 3 | Seed fescue

(with grass seed attachment on drill) |

| 4 | Harrow pack |

| June | 5 | Spray 2,4-D/Banvel |

| 6 | Spray Poast |

| Aug/Sept | 7 | Mow |

| 8 | Broadcast fertilizer |

|  |  |

| Year 2 - Production |

| May | 1 | Spray Ally/Venture |

| July | 2 | Swath |

| Aug | 3 | Combine/truck/augers |

| 4 | Bale (zero net cost)2 |

| Sept | 5 | Mow |

| Oct | 6 | Broadcast fertilizer |

| 2Assumption that returns for baling aftermath will cover costs. |

|  |  |

| Year 3 - Production |

| May | 1 | Spray Refine Extra/Assure |

| July | 2 | Swath |

| Aug | 3 | Combine/truck/augers |

| 4 | Bale (zero net cost) |

|  |  |

| Year 4 - Rejuvenate (field is either rotated back to annual crops or rejuvenated) |

| May | 1 | Plow |

| 2 | Roll |

| 3 | Float |

| Aug | 4 | Spray Banvel/2,4-D |

| 5 | Mow |

| Oct | 6 | Broadcast fertilizer |

|  |  |

| Year 5 - Production |

| May | 1 | Spray Ally/Venture |

| July | 2 | Swath |

| Aug | 3 | Combine/truck/augers |

| 4 | Bale (zero net cost) |

| Sept | 5 | Mow |

| Oct | 6 | Broadcast fertilizer |

|  |  |

| Year 6 - Production |

| May | 1 | Spray Refine Extra/Assure |

| July | 2 | Swath |

| Aug | 3 | Combine/truck/augers |

| 4 | Bale (zero net cost) |

| Sept | 5 | Plow |

Price and production sensitivity - The following table shows the impact on Contribution Margin in the established stand (year 5) resulting from a change in projected market returns and yields.

Price | Yields: lbs. per acre |

$/lb | 200 | 400 | 600 | 800 |

0.20 | -7.30 | 32.70 | 72.70 | 112.70 |

0.30 | 12.70 | 72.70 | 132.70 | 192.70 |

0.40 | 32.70 | 112.70 | 192.70 | 272.70 |

0.50 | 52.70 | 152.70 | 252.70 | 352.70 |

0.60 | 72.70 | 192.70 | 312.70 | 432.70 |

0.70 | 92.70 | 232.70 | 372.70 | 512.70 |

0.80 | 112.70 | 272.70 | 432.70 | 592.70 |

Certified seed usually commands a $.05/lb premium over common, but overall price levels are dependent on the American and European grass seed market.

Per Acre Costs & Returns for Straight Seeded Creeping Red Fescue Years of Production - 6

Click on PDF file for values PDF File

This information is provided as a guideline only. Projected yields indicate above average production. An individual crop plan should be developed by each producer. Planning forms may be obtained from your local Government Agriculture Office in British Columbia or Alberta.

References

Arnott, D.A. and Bergis, I. 1967. Casual agents of silvertop and other types of damage to grass seed crops. The Canadian Entomologist 99:660-670.

Berkenkamp, B. and Meeres, J. 1975. Observations on silvertop of grasses in Alberta. Canadian Plant Disease Survey 55:83-84.

Cole, D. and Darwent, A.L. 1990. Weed Control in Forage Crops. Alberta Agriculture Agdex 120/640-1.

Dobb, J.L. 1991. Fertilizing Creeping Red Fescue. Factsheet. B.C. Ministry of Agriculture, Fisheries and Food.

Dobb, J.L. and Nickle, K. 1992. Harvesting Creeping Red Fescue. Factsheet. B.C Ministry of Agriculture, Fisheries and Food.

Darwent, A.L. and Drabble, J.C. Experiments in Weed Control of Weeds in Grass Seed Crops, 1971-1996. Agriculture and Agri-Food Canada. April 1996

Fairey, N.A. and Lefkovitch, L.P. 1996. Crop density and seed production of creeping red fescue (Festuca rubra L. var. rubra) 1. Yield and plant development. Canadian Journal of Plant Science. 76:291-298

Fairey, N.A. and Lefkovitch, L.P. 1996. Ploidy and cultivar group differences in the thousand-seed weight of red fescue (Festuca rubra L.) Canadian Journal of Plant Science. 76:465-467

Fairey, N.A. 1997. Festuca rubra (creeping red fescue) in Canada. Pages 297-310 in D.T. Fairey and J.G. Hampton, eds. Forage Seed Production. Volume 1: Temperate Species. CAB International, Oxford, U.K.

Heide, O.M. 1994. Control of flowering and reproduction in temperate grasses. New Phytol. 128:347-362

Nickel, K. 1992. Weed, Disease and Insect Control in Creeping Red Fescue. Factsheet. BC Ministry of Agriculture, Fisheries and Food.

McDonald, M.B. Jr., Copeland, L.O., Knapp, A.D. and Grabe, P.F. 1996. Seed development, germination and quality. In (ed) Moser, L.E., Buxton, D.R. and Calser, M.D. Cool-season Forage Grasses. Agronomy N.34. Pages 15-70

Pringle, W.L., Elliot, C.R. and Dobb, J.L. Response of Creeping Red Fescue Seed Fields to Aftermath Grazing by Beef Cattle. Pages 59-64.

Technical input and review

Jack Dobb - Agricultural Consultant

George Monner - Farm Management Specialist, Alberta Agriculture and Rural Development

Jennifer Otani - Entomologist, Agriculture and Agri-Food Canada

Henry Najda - Grass Seed Agronomist, Alberta Agriculture and Rural Development

Nigel Fairey - Grass Seed Researcher, Agriculture and Agri-Food Canada

Owen Payeur - Peace Valley Seeds

Sandra Burton - Part Time Manager, Peace Region Forage Seed Association

Ken Nickel - Provincial Cereals and Oilseeds Specialist, BC Ministry of Agriculture, Fishereies and Food

Lloyd Darwent - Three-Links Agriculture Research

Garry Ropchan - Central Peace Conservation Society

Dan Cole - Weed Specialist, Alberta Agriculture and Rural Development

Prepared by:

Calvin Yoder - Forage Specialist, Alberta Agriculture and Rural Development

Photo credits:

Figure 1 - Nigel Fairey

Figures 3 to 10 - J.L. Dobb

Assistance in producing this factsheet provided by:

Peace Region Forage Seed Association

B.C. Ministry of Agriculture and Fisheries

Peace Region Forage Seed Trade

Source: Agdex 127/15-1. Revised November 2000. |

|