| | Background | Quarantine and seed/seedling certification | Disease monitoring, recognition and identification | Crop removal and clean-up practices

Cucumber green mottle mosaic virus (CGMMV) is an emerging disease in Canadian greenhouses. This disease is an increasing threat to cucumber and potentially to other greenhouse vegetable crops.

The damage CGMMV causes to cucumbers can be extensive and can result in substantial yield losses and a lower market value.

Background

The CGMMV virus is extremely stable and can survive several months in a greenhouse environment. This unique property of stability, combined with high infectivity through mechanical contact of the foliage of diseased and healthy plants, has elevated the economic importance of this virus.

Even only a few infected plants in a cucumber greenhouse can eventually lead to the spread of CGMMV to the entire crop. Additionally, infection may not be limited to the current crop but may also affect subsequent crops due to the long-term persistence of the virus.

Therefore, multiple approaches should be adopted to prevent or delay the introduction of the virus to cucumber greenhouses. Using more than one approach can help avoid or minimize the effect of CGMMV on cucumber production.

This factsheet offers several recommendations for the management of this significant new disease:

- quarantine and seed/seedling certification

- disease monitoring, recognition and identification

- crop removal and clean-up practices

- in-crop sanitation procedures

- premises sanitization

Quarantine and seed/seedling certification

Cucumber green mottle mosaic virus (CGMMV) is similar to other tobamoviruses (e.g. Tobacco and Tomato Mosaic Viruses) as it is seed-borne and can survive on seed in storage for several years.

Although the level of natural virus transmission through seed is relatively low, the ease of mechanical transmission of CGMMV from a contaminated seedling to adjacent plants, especially in propagation houses, makes this virus very contagious.

Seed treatment through thermal exposure or chemotherapy has been shown to provide some help in slowing down virus transmission. However, current seed treatment procedures are not completely effective at de-activating the virus and reducing its infectivity because the virus is so stable.

Therefore, the most effective means of defense against the potential introduction of CGMMV to a new cucumber crop is to use seed lots that have been tested and are certified to be free (no evidence) of the virus. The testing should be done using the standard International Seed Health Initiative (ISHI) approved protocols.

Cucumber seed companies routinely test for seed-borne viruses, including CGMMV. Therefore, plant propagators and cucumber growers should request that seed companies provide a copy of the test certificate showing freedom from CGMMV for their seed lots.

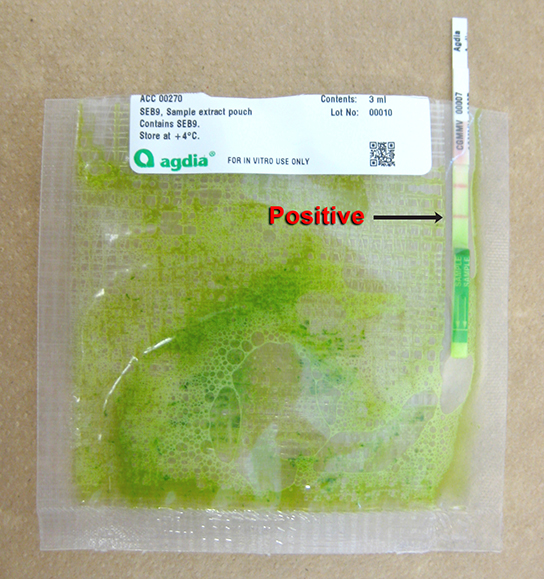

In addition to the use of certified CGMMV-tested seed lots, transplanted seedlings in the propagation house should be inspected. Representative suspect samples should be tested using an immunodiagnostic test specifically for CGMMV, to ensure freedom from the virus. The test is very simple and can be easily done by growers in their own greenhouses.

If grafted plants are used, then both scion (usually the top part of the grafted plant) and rootstock seeds should be tested to be found free of the virus. Strict hygiene best practices and an effective disinfectant (e.g., 2% Virkon) should be used during the grafting process to decontaminate tools to prevent potential cross-contamination of plants.

Disease monitoring, recognition and identification

The early infection of a cucumber seedling has a much more negative effect on plant growth and fruit production than infection on an older plant infected at a later growing stage. Rouging (identifying and removing) early infected younger plants to prevent the virus spread to crop plants in another area within a greenhouse should be considered soon after transplanting.

To ensure early detection of a CGMMV infection, walk through the greenhouse crop daily, and check to see if any plants are showing the characteristic symptoms of infection (see Figure 1).

Figure 1. Typical CGMMV symptoms on greenhouse cucumber plants

When visual symptoms are detected, growers can confirm the presence of CGMMV using a specific test kit. These kits are available from companies such as

Figure 2. Sample CGMMV test kit

Crop removal and clean-up practices

Pre-crop removal procedures

- Avoid overlapping crops to minimize the transfer of the virus from old to new plants.

- During the growing season, discard heavily infected plants and those with untreatable problems.

- Remove weeds and volunteer plants (roots too) to avoid “green bridging” of the virus between crops.

- Treat crops before removal using foliar pesticides, fumigants and/or heat to kill pests.

Crop removal procedures

- Apply an insecticide to prevent the spread of insect pests while the infested crop is being removed (the virus can be transmitted mechanically by insects with chewing mouth parts such as beetles):

- Use a broad-spectrum product (Dibrom, DDVP, Nicotine).

- Fogging is the best pesticide application method.

- Turn off irrigation systems and lower humidity to dry down plant material.

- Plan your strategy for crop removal:

- Use disposal bins and move them off site.

- To prevent pests from spreading back inside, do not pile infested crops next to the greenhouse.

- Avoid dragging hoses and equipment through piles of infested media and plant material.

- Remove all pots, trays, tools, etc. from the greenhouse to an area where they can be properly cleaned and disinfected.

- Do not store infected plant material in open containers in the greenhouse. Seal or cover the containers to reduce the spread of insects and pathogens.

- Pay attention to crop debris in out-of-the-way places, for example wires, screens, vents, pipes and on the legs of benches.

- Plant debris should be totally covered, buried or burned after crop removal.

Clean-up procedures

- Clean spilled media because organic matter will reduce the effectiveness of most disinfectants, especially oxidizers such as bleach and hydrogen peroxide.

- Clean and disinfect tarps or plastic sheets used over sand/gravel on floors.

- Clean tools with hot, soapy water and then rinse and disinfect them.

- Discard flats and pots after use or, if re-used, clean thoroughly and disinfect them.

- Clean and disinfect irrigation lines, drippers and the interior of water/nutrient tanks.

- Power wash the entire structure with a suitable detergent/cleaner solution to remove dirt, dust, crop residues and any remaining pests. Note, the presence of soil and organic matter can significantly reduce the effectiveness of disinfectants.

- Wash the structure from the top of the greenhouse down.

- Take extra care to wash down structural members, window ledges, tops of pipes, folds in plastic and textured surfaces.

- It may be necessary to rinse washed surfaces with water, depending on the detergent/cleaner, as the product may react with the disinfectant and neutralize it.

- Remember to wash down the floors, walkways, tables and fixtures in the header house.

- Replace landscape fabric if necessary.

- Clean and replenish footbaths and sanitization mats.

- Once the greenhouse is clean, close all vents and doors and let the greenhouse sit for a few days to heat up and kill any remaining pests.

- Hang sticky cards to monitor insect activity.

Greenhouse disinfection

- Based on research done at the Brooks Greenhouse and Research Production Complex in Alberta, the following steps are recommended for the disinfection of green-houses to manage CGMMV:

- Spray 2% Virkon solution on the exterior of coco slabs before removal from the greenhouse to reduce the risk of virus transfer during disposal.

- Once the clean-up procedures are complete, disinfect all walls, troughs and trays, etc. with 4% trisodiumphosphate (T.S.P.).

- Remember to disinfect the underside of troughs.

- Just prior to new crop transplanting, disinfect the entire greenhouse again with a 2% solution of Virkon (DIN #02125021).

In-crop sanitation procedures

The following are recommended procedures for in-crop sanitation to manage CGMMV during cucumber production:

- Place disinfection mats/tubs with a 2% Virkon solution at all entries to the production bays:

- Remember to change the solution at each break through-out the day to ensure the solution is still effective.

- If the solution is no longer dark pink, it has lost its efficacy and should be replaced immediately.

- At the end of each row, disinfect labcoats/clothing with a 2.1% solution of T.S.P. (trisodiumphosphate) using a spray bottle.

- At the end of each row, also disinfect hands/gloves, hand tools and carts/scissor lifts with a 1% Virkon solution.

- Walkways and corridors should be disinfected at least weekly with a 2% Virkon solution, being careful not to spray the plants as the product will cause damage to plant tissues.

Premises sanitization

Results of bioassays conducted at the Brooks Greenhouse and Research Production Complex in Alberta have shown that the spread of the virus can occur through contaminated baskets and pallets. Thus, to avoid potential cross-contamination between greenhouses, it is very important to take the following steps:

- Thoroughly clean baskets after each use with hot, soapy water and then rinse and disinfect them with a 2% solution of Virkon.

- Spray 2% Virkon solution onto the tops, sides and bottoms of wood and plastic pallets after each use.

- Cucumber storage areas, packing lines, walkways and corridors should be disinfected at least weekly with a 2% Virkon solution.

Prepared by

Walid Ellouze, Simone Dalpé and Wiezheng Zhang

Alberta Agriculture and Forestry

Crop Diversification Centre South

Ron Howard

RJH Ag Research Solutions Ltd.

Brooks, Alberta

Kai-shu Ling

USDA-ARS, U.S. Vegetable Laboratory

Charleston, South Carolina, U.S.A.

Acknowledgement

The authors gratefully acknowledge the financial support of the Alberta Crop Industry Development Fund (ACIDF), the Red Hat Co-operative, Doef’s Greenhouses and Growing Forward 2 – a federal-provincial-territorial initiative. The technical assistance provided by members of the Brooks Greenhouse Branch at Crop Diversification Centre South and the USDA Vegetable Laboratory is also sincerely appreciated.

More information, contact:

Alberta Ag-Info Centre

Call toll free: 310-FARM (3276)

Source: Agdex 256/635-1. January 2016. |

|