| | What is DDGS? | Nutrients in DDGS | Processing affects DDGS quality | Mycotoxins in DDGS | Obtaining DDGS | Feeding DDGS to nursery pigs | Feeding DDGS to grower-finisher pigs | DDGS effects on fat hardness | DDGS effects on carcass dressing percentage | Feeding DDGS to replacement gilts, sows and boars | Feed cost savings

Ethanol production from cereal grains results in a co-product that can be used to feed pigs to reduce feed costs. This co-product is called distillers dried grains with solubles (DDGS).

What is DDGS?

Distillers dried grains with solubles, or DDGS, is the main co-product of ethanol production. In North America, ethanol is produced primarily from cereal grains to blend with gasoline for automobiles.

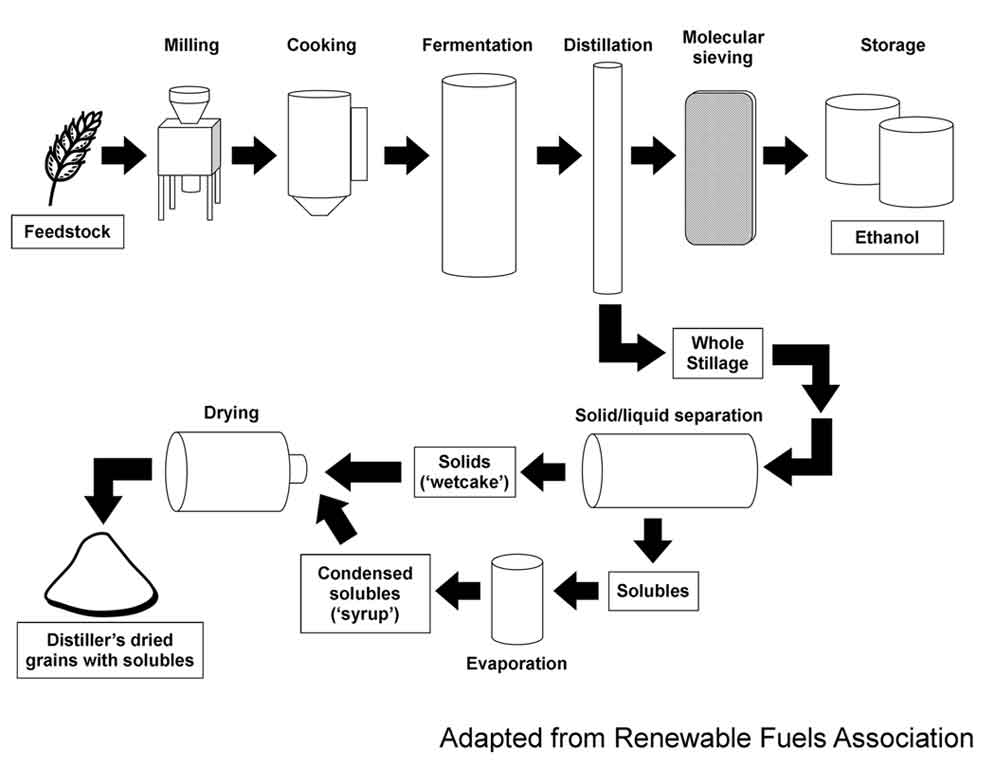

In the process of ethanol production (Figure 1), the sugars from starch in cereal grain are fermented by yeast to liquid ethanol, releasing carbon dioxide gas (CO2).

The remaining “wetcake” is distillers grains, to which the condensed solubles are added back at drying ending up with DDGS for feeding to livestock. Cereal grain yields about one-third ethanol, one-third CO2, and one third DDGS.

Figure 1. The process of ethanol production that yields DDGS as the main co-product for animal feeding.

Nutrients in DDGS

DDGS is a good source of dietary protein, fat, vitamins and minerals for livestock (Table 1). Because starch makes up about 70 per cent of the kernel weight of cereals, the fermentation process concentrates the remaining nutrients approximately three-fold.

The protein, fat and phosphorus content in DDGS reflects the grain or blend of grains fermented. In Western Canada, wheat and wheat-corn blends are the predominant feedstocks, yielding DDGS with a high protein content (36 %). In comparison, corn DDGS imported from the midwest US or produced in Ontario has more than twice the fat content (10.5 %) of wheat DDGS, owing to the higher oil content in corn grain compared to wheat.

Processing Affects DDGS Quality

In addition to the nutrient variability due to the grain stock, other factors such as the ethanol plant design and processing conditions affect the nutrient content and quality of DDGS. The amount of condensed solubles added back to the distillers grains (Figure 1) varies among the processing plants and affects the protein, fat and mineral content of DDGS. In addition, prolonged or excessive heating during the drying process scorches the protein in DDGS, reducing the availability of amino acids, in particular lysine.

Incomplete addition of solubles and scorching of DDGS were common occurrences in older ethanol plants, but these processing deficiencies are mostly a thing of the past. Modern ethanol plants produce a high quality DDGS product. However, some plants are now extracting the oil from corn DDGS, which reduces its dietary energy value, making it comparable to that of wheat DDGS (5%).

Table 1. Nutrient content (8 % moisture), standardized ileal digestibility (SID) of crude protein and amino acids, energy values and apparent total tract digestibility (ATTD) of gross energy and phosphorus for corn and wheat DDGS

| Nutrient, % | Corn1 | Wheat2 | Digestibility, % | Corn1 | Wheat2,3 |

| Protein | 27.38 | 39.79 | SID protein | 72.8 | 73 |

| Arg | 1.14 | 1.56 | SID Arg | 81.1 | 88.86 |

| Cys | 0.52 | 0.69 | SID Cys | 72.5 | 84.9 |

| His | 0.71 | 0.75 | SID His | 77.1 | 86.12 |

| Ile | 1 | 1.31 | SID Ile | 75.3 | 87.55 |

| Leu | 3.11 | 2.45 | SID Leu | 83.5 | 89.78 |

| Lys | 0.76 | 0.86 |  |  |  |

| Avail. Lys | 0.67 | 0.7 | SID Lys | 60.6 | 71.72 |

| Met | 0.54 | 0.55 | SID Met | 81.8 | 88.74 |

| Phe | 1.32 | 1.6 | SID Phe | 80.8 | 90.26 |

| Thr | 1.04 | 1.09 | SID Thr | 70.4 | 80.58 |

| Try | 0.21 | 0.38 | SID Try | 69.6 | 87.62 |

| Tyr | 1.04 | 1.1 | SID Tyr | 80.9 | 89.13 |

| Val | 1.34 | 1.62 | SID Val | 74.4 | 86.25 |

| Crude fat | 10.48 | 4.69 |  |  |  |

| Starch | 7.3 | 3.86 | GE, kcal/kg | 5000 | 4676 |

| Crude fibre | 5.64 | 6.56 | ATTD% GE | 76.8 | 68.61 |

| ADF | 9.9 | 13.8 | DE, cal/kg | 3809 | 3392 |

| NDF | 25.3 | 39.1 | ME, kcal/kg | 3585 | – |

| Ash | 3.86 | 4.88 | NE, Mcal/kg pigs | 2.3 | 2 |

| Calcium | 0.04 | 0.18 | NE, Mcal/kg sows | 2.4 | 2.1 |

| Phosphorus | 0.61 | 0.83 | ATTD% Phosp. | 59.1 | 55.45 |

Maximum mycotoxin tolerances (ppm): aflatoxin 0.005, vomitoxin 3.0, fumonisin 0.02, zearalenone 0.10.

Data provided as reference. The reader assumes responsibility for use and interpretation.

1Stein, H. H. and G. C. Shurson. 2009. J. Anim. Sci. 87:1292-1303

2Proximate data from http://www.ddgs.usask.ca/NutrientProfile.aspx

3Amino acids data and digestibility coefficients from Beltranena, E. and R. T. Zijlstra 2008. Advances in Pig Production 19:263-273

Swine diets should be formulated on the basis of net energy (NE). Formulating on a digestible (DE) or a metabolizable (ME) energy basis does not account for the greater heat increment of feeding induced by high protein, high fibre feedstuffs like DDGS. If the heat loss is not accounted for, increasing dietary inclusions of these feedstuffs results in greater reductions in pig performance.

Mycotoxins in DDGS

Mycotoxins are produced by moulds stressed by weather variation and extremes or insect damage to crops in the field. Mycotoxins are not destroyed during fermentation, and like non-starch nutrients, they also concentrate three-fold in DDGS. Mould growth may continue to rob grain of nutrients in storage after harvest, resulting in contamination that is not evenly spread but localized to “hot spots.”

The variation in the lab results of mycotoxin analysis is largely due to sampling errors (90 %). Therefore, producers should collect large samples (about 3 kg) and analyze as many as they can afford. It is better to analyze 50 samples by low cost, broad-scanning ELISA than 1 sample by the more costly, but precise high pressure liquid chromatography (HPLC).

Feeding mycotoxin-contaminated grain or DDGS to pigs may cause a number of problems: feed refusal, weight loss, vomiting, unthriftiness, rough hair, abortions, red vulvas, etc. Instead, contaminated DDGS should be fed to beef cattle and poultry that are more tolerant to mycotoxins than pigs. Or, the DDGS can be diluted with uncontaminated grain before feeding to pigs.

Mycotoxin contamination of DDGS is a sporadic problem rather than the norm, so it may not be worthwhile to miss out on feed cost savings. At times when mycotoxin incidence is high, producers may decide to exclude DDGS from rations for a few months. Ethanol plants do have screening procedures in place to monitor mycotoxin levels in incoming grain and outgoing DDGS.

Obtaining DDGS

Variation among DDGS lots requires nutritionists to routinely adjust nutrient values to match that received. Feed mill managers should discount, or even reject, loads that do not meet guarantees. Proper sampling, retention and analytical testing are necessary to compare newly arriving loads with historical nutrient and mycotoxin levels.

A plant-specific procurement contract is recommended that includes minimums for protein, fat, ash, phosphorous and available lysine as well as maximums for moisture, ADF, NDF (or crude fibre), mycotoxins content, colour (dark indicates burnt) and syrup balls size. Lab testing pays back quickly when results exceed specifications, magnifying feed cost savings, and producers can decide among processing plants regarding product consistency over time.

Feeding DDGS to Nursery Pigs

A step-up inclusion strategy by feeding phase is recommended for weaned pigs to allow them to progressively adapt to the flavour and fibre content of diets containing DDGS (Figure 2). The inclusion of DDGS should not exceed 5 per cent for the first week post-weaning. Dietary inclusion levels can progressively increase thereafter (e.g. 10 % the second week and 20 % the third week post-weaning). To maintain performance, restrict the dietary inclusion of wheat to 15 per cent or corn DDGS to 30 per cent in nursery diets for pigs up to 20 kg.

Figure 2. Weaned pigs need to progressively adapt to feeding DDGS.

Including DDGS in nursery diets may have gut health benefits. Results from one US study suggest that feeding corn DDGS may reduce the incidence and severity of lesions caused by a moderate ileitis outbreak in nursery age pigs.

Feeding DDGS to Grower-finisher Pigs

Common inclusions of DDGS in hog diets range from 7.5 to 15 per cent. The high fat content of corn DDGS (10.5 %) returns the most in feed cost savings when feeding high levels to growing pigs. Up to 30 per cent wheat DDGS or 40 per cent corn DDGS can be fed to hogs until weeks before slaughter weight. However, a DDGS removal strategy must be implemented to mitigate the effect on pork fat hardness and the reduction in carcass dressing percentage.

DDGS Effects on Fat Hardness

The high proportion of unsaturated fatty acids in DDGS, in particular linoleic acid, softens pork fat. These fatty acids cause bacon slices to stick together and convey an oily appearance to high fat processed pork products like sausage (30 % fat), but not to lean products like ham (<15 % fat).

Asian consumers prefer harder fat because fresh pork is often thin-sliced and boiled or grilled for traditional dishes. Therefore, for hogs fed high DDGS levels (30 to 40 %), the removal of DDGS from the diet (withdrawal) for 3 to 4 weeks before slaughter is necessary to restore pork fat hardness (Figure 3). Producers should implement a 2-week withdrawal period if feeding DDGS at 15 to 20 per cent of the diet. No dietary removal is necessary if feeding DDGS at 5 to 15 per cent of the diet through to market weight.

Figure 3. Pork fat softness can be a marketing issue preventable by withdrawing DDGS from the finishing diet.

Feeding corn DDGS softens pork fat more than wheat DDGS due to the former having more than twice the grain oil content. The effect on fat softness is compounded by feeding corn grain instead of wheat-barley-based diets.

The dietary inclusion of DDGS has a greater effect on fat hardness in gilts than barrows because their carcasses are leaner than those of barrows. The DDGS withdrawal period for gilts should therefore begin 7 to 10 days sooner than for barrows.

It is important for producers considering high dietary inclusions of DDGS to discuss the intended market for their pork with packers and implement a withdrawal strategy tailored to the type of DDGS (corn or wheat) and amount fed. Stressing hogs before slaughter or providing extended carcass chilling can increase the incidence of pale, soft and exudative (PSE) pork from hogs fed DDGS. Slaughter plants should provide proper lariage conditions and implement blast-chilling of carcasses.

DDGS Effects on Carcass Dressing Percentage

Feeding DDGS reduces the carcass dressing percentage by 0.4 per cent-units for each 10 per cent increase in dietary inclusion. The high fibre content of DDGS increases gut fill and thickens the gut wall, reducing carcass weight at evisceration. To compensate for this reduction in dressing percentage, producers should completely withdraw DDGS from the finisher diet 2 to 3 weeks before slaughter in favour of a lower-fibre feedstuff.

Feeding DDGS to Replacement Gilts, Sows and Boars

Common inclusions of DDGS in sow diets range from 10 to 20 per cent (Figure 4). Gestation diets for gilts and sows can include as much as 30 per cent wheat DDGS or 40 per cent corn DDGS. Limit wheat DDGS to 20 per cent and corn DDGS to 30 per cent in lactation diets, and introduce DDGS progressively.

Figure 4. Sow diets can include DDGS, but sows should adapt to the taste of DDGS.

Feed refusal and wastage will be observed if sows are not accustomed to the taste of DDGS. Conservative dietary inclusions (5 - 15 %) are recommended for the first week after farrowing and wean-to-breeding period.

Due to microbial fermentation in the hindgut, sows can derive slightly more energy from DDGS than young pigs (see NE values in Table 1). Avoid feeding mycotoxin-contaminated DDGS to pregnant sows (risk of abortion) and boars (affects spermatogenesis).

Feed Cost Savings

The following tables illustrate the feed cost savings that can be achieved by dietary DDGS inclusions.

Table 2. Feed cost savings by increasing dietary WHEAT DDGS inclusions by 10 %

| Ingredients, % | 0% DDGS | 10% DDGS | 20% DDGS | 30% DDGS | For each 10% DDGS |

| Wheat grain | 67.53 | 61.82 | 56.13 | 50.44 | -5.7 |

| Soybean meal | 15 | 10 | 5 | – | -5 |

| Wheat DDGS | – | 10 | 20 | 30 | 10 |

| Field pea | 15 | 15 | 15 | 15 |  |

| Tallow | – | 0.6 | 1.2 | 1.8 | 0.6 |

| Limestone | 1.03 | 1.05 | 1.08 | 1.1 | 0.03 |

| Phytase | 0.04 | 0.03 | 0.02 | 0.01 | -0.01 |

| Salt | 0.35 | 0.35 | 0.35 | 0.35 |  |

| L-Lysine HCl | 0.13 | 0.22 | 0.31 | 0.4 | 0.09 |

| L-Threonine | 0.06 | 0.07 | 0.07 | 0.07 |  |

| Vitamin premix | 0.4 | 0.4 | 0.4 | 0.4 |  |

| TM premix | 0.4 | 0.4 | 0.4 | 0.4 |  |

| $/1000 kg | 266.62 | 259.4 | 251.25 | 243.27 | ($7.78) |

| Provided per kg of diet |  |

| NE, Mcal/kg | 2.33 | 2.33 | 2.33 | 2.33 |  |

| gSIDlys/McalNE | 3.81 | 3.81 | 3.81 | 3.81 |  |

| SIDthr/SIDlys | 0.67 | 0.67 | 0.67 | 0.67 |  |

| SIDmet/SIDlys | 0.34 | 0.34 | 0.34 | 0.34 |  |

| SIDtry/SIDlys | 0.22 | 0.21 | 0.21 | 0.2 |  |

| Avail. Phos, % | 0.25 | 0.25 | 0.25 | 0.25 |  |

Central Alberta prices for September 10, 2011: wheat $200, SBM $424, DDGS $180, field pea $238, tallow $900, Lys. HCl $2670 per tonne

Tables 2 and 3 present four grower diets, each formulated to the same dietary energy, lysine-to-energy ratio and available phosphorus content containing either wheat DDGS for central Alberta or corn DDGS for southern Manitoba. Each 10 per cent increase in DDGS inclusion reduced the feed cost by $7.80 or $6.70, respectively, largely through displacing soybean meal from the diet.

The higher phosphorus content and availability in DDGS compared to grain eliminated the need to supplement phosphorus from inorganic sources and decreased pyhytase inclusion.

Due to the higher oil content, increasing the corn DDGS level reduced tallow inclusions (Table 3). In contrast, increasing the wheat DDGS level required the addition of tallow to the diets to equalize dietary energy values.

The price of DDGS fluctuates relative to other feed commodities and according to freight cost (distance) from suppliers. In conclusion, feeding DDGS can reduce feed costs and increase producers’ profitability, but the savings in the cost of feed vary regularly in different parts of Canada.

Table 3. Feed cost savings by increasing dietary CORN DDGS inclusions by 10 %

| Ingredients, % | 0% DDGS | 10% DDGS | 20% DDGS | 30% DDGS | For each 10% DDGS |

| Wheat grain | 66.28 | 61.19 | 56.16 | 51.02 | -5.09 |

| Soybean meal | 15 | 10 | 5 | – | -5 |

| Corn DDGS | – | 10 | 20 | 30 | 10 |

| Canola meal | 15 | 15 | 15 | 15 | |

| Tallow | 1.6 | 1.5 | 1.3 | 1.2 | -0.13 |

| Limestone | 0.88 | 0.95 | 1.05 | 1.15 | 0.09 |

| Phytase | 0.04 | 0.03 | 0.02 | 0.01 | -0.01 |

| Salt | 0.35 | 0.35 | 0.35 | 0.35 | |

| L-Lysine HCl | 0.07 | 0.18 | 0.3 | 0.42 | 0.12 |

| L-Threonine | – | – | 0.03 | 0.05 | -0.02 |

| Vitamin premix | 0.4 | 0.4 | 0.4 | 0.4 |  |

| TM premix | 0.4 | 0.4 | 0.4 | 0.4 |  |

| $/1000 kg | 306.83 | 298.13 | 289.49 | 286.76 | ($6.69) |

| | Provided per kg of diet |  |

| NE, Mcal/kg | 2.31 | 2.31 | 2.3 | 2.3 | |

| gSIDlys/McalNE | 3.8 | 3.8 | 3.8 | 3.8 | |

| SIDthr/SIDlys | 0.7 | 0.67 | 0.67 | 0.67 | |

| SIDmet/SIDlys | 0.35 | 0.35 | 0.35 | 0.35 | |

| SIDtry/SIDlys | 0.25 | 0.23 | 0.2 | 0.19 | |

| Avail. Phos, % | 0.25 | 0.25 | 0.25 | 0.25 |  |

Southern Manitoba prices for September 10, 2011: wheat $250, SBM $408, DDGS $228, canola meal $268, tallow $900, Lys. HCl $2670 per tonne

Prepared by

Eduardo Beltranena, PhD

Alberta Agriculture and Rural Development

Telephone (780) 427-4567

E-mail eduardo.beltranena@gov.ab.ca

For more information, contact

Alberta Ag-Info Centre

Call toll free 310-FARM (3276)

Source: Agdex 440/68-1. November 2011. |

|