| |

Shallow Well Jet Pumps | |

| |

|

|

| |

|

|

| | Limitations | Priming | Maintenance

Shallow well jet pumps are practical for wells or reservoirs that require a total pumping lift of less than 5.5 m (18 ft).

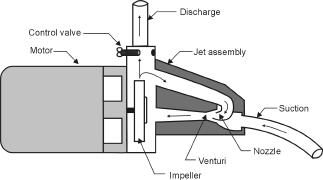

The three main components of the shallow well jet pump are an electric motor, an impeller and a jet assembly. Although a simple centrifugal pump would pump water at this lift, including a jet assembly will greatly increase the discharge pressure and suction. This combination makes the shallow well jet pump suitable for use in farm water pressure systems. Figure 1 shows the flow of water in a typical shallow well jet pump.

Figure 1. Shallow well jet pump operation.

Advantages of shallow well jet pumps:

- can be offset from the well

- can be adapted to wells of various yields

- are mechanically simple and require little maintenance

- are relatively inexpensive

- can be used in wells of small diameter

Limitations

Jet pumps lose efficiency as the total lift increases. Total lift includes the vertical distance from the water to the pum plus the friction losses in the suction line and foot valve. Shallow well jets are not practical if the total lift exceeds 5.5 m (18 ft).

Pumping water containing sand will cause wear and leakage around mechanical seals. The mechanical seal on the pump shaft is water lubricated and water cooled, so the pump should never be run without the pump casing being filled with water. Air or gases in the pump will cause a loss of prime. Shallow well jet pumps must have either a check valve or foot valve installed on the suction line to maintain prime.

Priming

To prime a shallow well jet pump:

- Fill the suction line and pump casing with water.

- Close the pump control valve.

- Leave the priming plug slightly loose and start the pump.

- Stop the pump when the air stops bubbling out around the priming plug.

- Refill the pump casing with water, replace priming plug loosely and start the pump.

- When the pump is fully primed, water will flow out continuously around the priming plug.

- Tighten the priming plug and open the pump control valve.

- After the pump has been primed, it may be necessary to precharge the pressure tank. See Agrifacts 716 (C31) Pressure Tanks.

When trenching and laying the suction line in the trench, make sure there are no high points in the line where an airlock can form, causing difficulties in priming.

Maintenance

No regular maintenance is required on jet pumps (Figure 2). However on new installations, the nozzle may become partially or completely plugged with plastic cuttings or dirt. When this situation occurs, it may pump water but will not build up to “cut out” pressure. A pump that is pumping silt or sand will wear around the eye of the impeller, thus reducing both the pumping capacity and the maximum pumping pressure. Allowing the pump to run dry will cause leakage through the pump shaft seal.

Figure 2. Shallow well jet pump installation.

For more information

Alberta Ag-Info Centre

Call toll-free: 310-FARM (3276)

Website: www.agriculture.alberta.ca

Prepared by

Alberta Agriculture and Rural Development

Source: Agdex FS716(C12), April 2005 |

|

| |

|

|

| |

For more information about the content of this document, contact Brandon Leask.

This document is maintained by Jennifer Rutter.

This information published to the web on April 1, 2000.

Last Reviewed/Revised on November 24, 2016.

|

|