| | Boar taint | How the product works | Male pig immunocastration | Challenges

Boar taint is an unpleasant odour and taste discernible when cooking and eating pork from sexually maturing male pigs. An unpleasant experience with boar taint once can cause consumers to reject pork in the future.

Except for some countries, boar taint is minimized through the widespread practice of castrating male pigs destined for the food chain. The surgical castration of young pigs is generally carried out without anaesthesia and analgesia, resulting in mounting consumer concern over the animals’ welfare, which could reduce pork consumption.

Surgical castration also deprives the male pig of testicular steroids that naturally enhance growth rate, feed efficiency, lean tissue growth and reduce the fat content of pork of intact males compared with barrows (surgically castrated males). An immunological product soon to be registered in Canada and the US will minimize the incidence of boar taint in pork while allowing male pigs to express their potential for lean growth.

Boar Taint

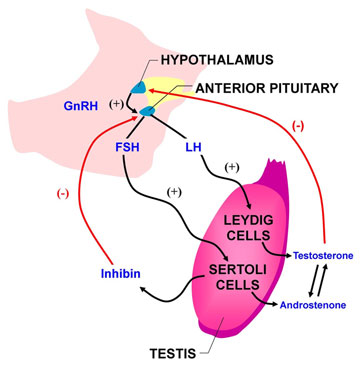

Two compounds, androstenone and skatole, are primarily responsible for boar taint in pork. As male pigs approach sexual maturity (puberty), the lower part of the brain (hypothalamus) releases gonadotrophin-releasing hormone (GnRH) that stimulates the pituitary gland at the base of the brain to release two other hormones, follicle-stimulating hormone (FSH) and luteinizing hormone (LH) (see Figure 1).

These hormones stimulate the growth of the testes and, in turn, the production of testicular steroids. One of them, androstenone, is a pheromone that concentrates in saliva. Skatole is a by-product of tryptophan metabolism, a feed amino acid, by bacteria in the hindgut.

Pigs of both sexes absorb skatole through the skin into subcutaneous fat when they lie down in manured pens. Intact males are less efficient at breaking down skatole compared with gilts or barrows. Androstenone and skatole that accumulate in the fat tissues of intact male pigs are then detectable by consumers when cooking or eating pork.

The novel technology of immunocastration does not deprive male pigs of the natural muscle-building influence of testicular steroids until near market weight when it also makes possible the clearance of compounds responsible for boar taint from the fat in immunized male pigs.

Figure 1. GnRH indirectly stimulates androstenone production by the testis.

How the Product Works

This immunological product triggers the pig’s immune system to produce antibodies that target its own GnRH. The first immunization stimulates the young pig to develop antibodies that bind its own GnRH. The second immunization elicits a much stronger immune response that neutralizes GnRH production in the older animal.

Therefore, young male pigs grow normally under the influence of their own naturally occurring growth factors that enhance lean deposition until the second immunization. The second immunization also suppresses fighting, chasing, mounting and penis exposure, behaviours typically observed in boar pens as they attain puberty. Immunocastrates thus spend less energy fighting and divert it instead toward more time eating.

A few additional weeks are necessary to clear the compounds responsible for boar taint from fat tissue.

Improvest® anti-GnRH immunizationprotocol:

- The first vaccination is given to male pigs between 30 and 60 kg while they are not stressed by weaning, moving or mixing.

- The second vaccination is given 4 to 6 weeks prior to shipping for slaughter, inducing immunocastration.

- A minimum of 4 weeks is required between the priming and second immunizations.

The new immunological product will be called Improvest® in Canada and the US, Vivax® in Brazil, Innosure® in Central America, Colombia and Venezuela, and Improvac® in most other countries. The product is made by Pfizer Animal Health. Alberta Agriculture and Rural Development does not endorse a specific product or company; however, this is the only product of this type currently on a registration path with Health Canada.

Male Pig Immunocastration

Benefits

- Market access. The pain and suffering of castrating pigs without anaesthesia and analgesia is not the perception Alberta wants domestic or foreign consumers to have. Korean and European consumers found immunization to control boar taint to be preferable on animal welfare grounds compared with physical castration as long as there was equivalent pork taste.

- Safer pork without boar taint. Lightweight slaughter of boars marketed as meat animals, as it is customary in some European countries, cannot prevent early maturing boars and hence the possibility of taint due to large natural variation in sexual precocity. Anti-GnRH immunization suppresses the fighting, chasing and sexual behaviour observed in boar pens around market weight. Anti-GnRH immunization also addresses boar taint from cryptorchid and intersex animals.

- Less fat in pork. Pork from immunocastrates has less fat than that of barrows and is more consistent with that of gilts. A review of 28 studies found that immunocastrates averaged 10.2 per cent less backfat than barrows. The equivalent of years of genetic selection for reduced backfat can be achieved with 2 injections 4 to 8 weeks apart. Retailers will, therefore, sell leaner and more uniform pork to consumers.

- Lower dressing but heavier carcasses. A review of 25 studies found that dressing was reduced from 78.2 to76.6 per cent due to the removal of involuted testes and internal sexual accessory glands. A review of 28 studies found that immunocastrates averaged 2.8 kg heavier carcass weights than barrows. Carcasses from immunocastrates were, therefore, only 0.3 kg heavierthan those of barrows.

- More lean pork per processed carcass. A review of16 studies found that immunocastrates averaged4.6 per cent higher lean yield percentage than barrows. From 14 studies, loin eye area was 1.7 per cent larger in immunocastrates compared with barrows. Heavier primal cuts and higher lean yield have also been reported, with country cutting differences being evident. Packers thus benefit by processing carcasses that yield more separable lean pork per employee-hour.

- Similar pork quality as gilts and barrows. A review of17 studies found no differences in objective pork quality measurements between immunocastrates and barrows (pH, drip loss, shear force, colour). From 15 studies, the sensory assessment of pork from immunocastrates was judged by panellists to be similar to pork from either barrows or gilts.

- More profit for pig producers. Immunocastrates divert more feed into lean growth compared with barrows that instead get fatter (8 per cent better feed conversion). Producers may also realize lower male mortality (1.5 per cent) compared with barrows due to wounds that allow disease entry requiring antibiotic therapy.

- Reduced environmental footprint. Immunocastrates divert more feed into pork and, therefore, excrete less manure than barrows. Less land and water resources are utilized, resulting in a net 6 per cent reduction in greenhouse gas emissions.

Challenges

- Global pork competitiveness. Australia, New Zealand, Brazil, Chile, Mexico and other major pork exporters already have access to this immunological product. It has now been approved for use in European Union member countries and will soon be registered in the US, China and Japan.

- Consumer acceptance. This immunological product only triggers an immune response in treated pigs, not in humans consuming pork from treated pigs. It leaves no residues in meat, has zero withdrawal and is not active when given by mouth. This product is NOT a drug, hormone, animal product or genetically modified material of any kind. Consumer education will be important in gaining acceptance of this technology over time.

- Critical control points. Boar taint screening at high speed pork processing plants is a logistical challenge. Producers must set up primary control points to ensure that male pigs that are missed are caught and held on-farm. Therefore, the onus to catch missed male pigs will rest with the producer, not with the packer.

- Phased-in at pork plants. Slaughter of immunocastrates could be phased-in by packers initially accepting immunocastrates only on specific days and times from audited producers with confirmed procedures and training in place. Secondary control points at abattoirs may include screening testes size at receiving, before or after scalding and examination of male sexual gland size at evisceration. Fat boiling and sniffing is too time consuming and unreliably subjective. Tissue reaction at the injection sites is not common, but should be inspected.

- Worker safety. A safety applicator is provided with the vaccine. However, technicians doing the injecting should wear gloves and leg protectors to prevent accidental self-injection.

- Injecting male pigs. Anti-GnRH immunization of male pigs will be carried out in growout barns. Therefore, gender segregation at filling the barns will be necessary. Proper handling when injecting hogs should be implemented to protect animals from injury. The two vaccinations required increase the chances of broken needles that need reporting as well as trimming of carcasses in the neck area.

- Product cost. The cost associated with purchasing this immunological product, the additional labour required for application and the implementation of farm critical control points to screen for missed males can only be slightly higher than the cost of physical castration.

- Training. Barn personnel must receive training to identify missed males that display aggressive sexual behaviour like chasing, mounting attempts, penis exposure and those that have large testes with a reddened scrotum. Receiving personnel at abattoirs should have similar training. Evisceration personnel and line inspectors should be able to distinguish intact boars from immunocastrates. Anti-GnRH immunization of male pigs induces a one-third reduction in the size of the testes and a more evident three-quarters reduction in the weight of the internal sexual glands compared with boars.

References

Allison, J. 2010. Proceedings Pfizer International Swine Symposium, Ottawa, ON

Crane, J. 2010. Proceedings Pfizer International Swine Symposium, Ottawa, ON

Hennesy, D. 2010. Proceedings Pfizer International Swine Symposium, Ottawa, ON

McKeith, F. K. et al. 2009. Proceedings International Congress of Meat Science & Technology (ICoMST), Copenhagen, Denmark

Moraes, P. Proceedings Pfizer International Swine Symposium, Ottawa, ON

Prepared by

Alberta Agriculture and Rural Development

For questions or additional information, contact

Eduardo Beltranena

Telephone (780) 427-4567

Alberta Ag-Info CentreCall toll-free: 310-FARM (3276)

Source: Agdex 443/67-1. October 2010. |

|