| |

Home

Farmer/Rancher Safety

Young Farm Worker Safety

Children's Safety

Media

|

Big, mean farming machines | Unavoidable hazards | Diagram of a PTO with parts labelled | Driver abuse | What's the drill? | After the injury | Shield sense | The last word | References

A Power Takeoff (PTO) shaft is an efficient way to transfer mechanical power between a farm tractor and an implement. It’s also a very efficient way for you to seriously injure yourself. All it takes is a thread hanging from your shirt, a shoelace, the string from a parka, or a strand of hair. Whatever it gets hold of, a PTO will grab it and take you down with it before you know what hit you. The painful outcome may be amputation, severe lacerations, multiple fractures, spine and neck injuries, or even death.

To prevent PTO injuries and fatalities, know the job, know the hazard, know the drill. In other words get trained, learn to recognize PTO-related hazards and learn how to reduce or eliminate those hazards in a safe way.

|

Big, Mean Farming Machines

Machinery helps us accomplish an amazing amount of work on the farm. But those big, mean farming machines can also be your worst enemy. The best strategy is to get well trained before you turn the key. When it comes to PTO-powered equipment, knowledge is critical. Learn as much as you can about the implement and the PTO itself. Ask lots of questions ahead of time to ensure you will recognize potential hazards. The reality is you won’t win any

wrestling matches against several tons of steel. You may not be stronger, but you can be smarter. Get the training you need to operate the machinery safely. Know the job.

Unavoidable Hazards

In an ideal world, we could learn to recognize hazards and then just avoid them completely. While a PTO is a recognizable hazard, this is one situation in which there is no way to avoid it – working with PTOs is going to be part of your job. So learn to protect yourself. Know the hazard.

When you are familiar with PTO hazards, you’ll be more likely to recognize them on the job. Here is a brief description of the parts of a PTO that are likely to cause injury:

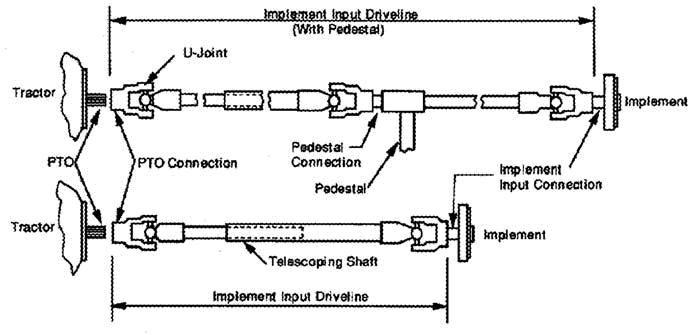

Diagram of a PTO with Parts Labelled:

- The PTO stub can cause serious injury when loose clothing gets caught in it. Never leave an operating PTO stub unguarded, and always disengage it when it’s not in use.

- The machine shaft is coupled to the PTO stub. Clothing may be pulled around the shaft much quicker than you expect. You’ll naturally take evasive action, pulling away; unfortunately, this simply results in a tighter, more binding wrap.

- Protruding pins and bolts snag clothes easily. Hopefully the clothing will tear. If it doesn’t, your limb or body may begin to wrap with it, or it may become compressed, trapping you against the shaft. Always follow manufacturer’s recommendations when replacing damaged pins or bolts.

Driver Abuse

Want to keep your PTO happy? It’s all in how you drive. To reduce PTO shaft abuse:

- Avoid tight turns.

- Keep excessive telescoping to a minimum.

- Engage power to the shaft gradually.

- Do not over-tighten the slip clutch on a PTO-driven machine.

|

What’s the Drill?

So you know how PTOs work. You know the hazards that could cost you a limb or your life. Now how are you going to avoid them? Take responsibility for your own safety. Learn how to avoid the hazards you encounter on the job.

Proper use of shields and guards is critical. They are designed to help you work safely. Use them. But there is more you can do to ensure your safety. Know the drill. Here are some safety guidelines to help you safely manage PTOs on the job.

- Always disengage the PTO, shut off the engine and remove the key before getting off the tractor.

- Keep the master shield in place. Only remove it to hook up equipment with an equivalent shield. Replace it when PTO-driven equipment is not in use.

- Ensure PTO driveline shields are in good condition. Test them when the PTO is stopped by rotating them to ensure they are not stuck. They should rotate freely by hand.

- Clean the driveline shields frequently, and replace worn or damaged bearings or shields based on the manufacturer’s recommendations.

- Never modify driveline shields to make servicing or connections easier. Always use the driveline recommended for your machine.

- Never step across a rotating PTO driveline. Walk around.

- Follow safe practices when mounting or dismounting the tractor.

- Never reach for the controls from the rear of the tractor.

- Don’t take passengers. Only one person should ride on a tractor – the driver.

- Adjust the length and height of the tractor drawbar to match your implement’s specifications. These adjustments ensure the PTO driveline does not compress or separate during sharp turns or at the top or bottom of a hill.

- Wear snug-fitting clothing without dangling strings or laces.

After the Injury

It’s too late. You’ve found a fellow worker stuck in a PTO. Now what? Use caution. The critical time to remove them might be a few minutes or several hours, depending on the situation. To prevent further damage to trapped limbs,

follow the correct procedure:

- Shut off the tractor. Make sure it can’t re-start.

- Chock the wheels so the tractor can’t move.

- Place the PTO drive unit in neutral and turn the shaft counter-clockwise to unwrap the person. You may need a large pipe wrench to turn it. You may also try putting a small bar into the yoke of the PTO unit and turning with considerable pressure.

- Try disconnecting the hitch pin that attaches the equipment to the tractor. Then move the tractor forward to pull the PTO shaft apart. Then turn the shaft counter-clockwise to remove the victim. If the shaft is solid, rescuers may have to cut it.

- Never use tractor power to rotate the shaft.

- Use caution if flame- or spark-producing rescue equipment is required.

- Monitor the victim’s vital signs and prevent unnecessary movement.

- If necessary, transport the victim while they are entangled with part of the shaft. A surgeon can complete the extrication in the hospital.

- If a body part was amputated, it should be kept with the victim. Rinse it in a saline solution, wrap it in a clean, moist towel and place it in a plastic bag.

Shield Sense

Besides your own good sense, your next best defence against PTO injury is protective shields and guards. They are on your tractor, on the PTO, and often on your implement too. They’ll protect you against injury – if you use them properly.

- The master shield on the rear of the tractor prevents you from getting pinched, crushed or wrapped by the stub shaft or front universal joint on the equipment’s driveline.

- The PTO shaft guard covers the tractor stub shaft to prevent wrapping. Replace it when the PTO is not in use.

- A fully shielded driveline is encased and supported by bearings at each end. The bearings stop the shield from spinning if something connects with the driveline. The shaft inside the shield continues to spin.

- Manufacturer-installed guards protect you and the equipment. They prevent injury and keep dust and foreign objects out. Don’t operate without them.

|

The Last Word

The painful truth is that farm machinery is a powerful friend that can turn foe at any moment. You could be cut, crushed, pulled in, wrapped, pinched, or sheared. To protect yourself, get trained before you operate the equipment. Learn to recognize hazards that could cause injury or death. Then take responsibility for your own safety by making the commitment to manage PTO-related hazards before they pull you in.

References

Safety with Agricultural Tractors, Farm Safety Association Inc., Guelph, ON

Power Take-off Safety, Dennis J. Murphy, Penn State University

Return to top

Alberta Farm Safety Program

Email: farm.safety@gov.ab.ca

or toll-free: 310-FARM (3276)

Alberta Agriculture and Forestry Farm Safety Staff:

Janice Donkers, Youth Coordinator: janice.donkers@gov.ab.ca

Kenda Lubeck, Coordinator: kenda.lubeck@gov.ab.ca

Raelyn Peterson, Coordinator: raelyn.d.peterson@gov.ab.ca

Sharon Stollery, Manager: sharon.stollery@gov.ab.ca

Blair Takahashi, Specialist: blair.takahashi@gov.ab.ca |

|