| | Are you ready to seed? | Choosing the correct species | Field and seedbed preparation | Inoculation of legumes | Seed treatment | Time of seeding | Fertility during establishment | Seed placement | Companion crops | Seed quality | Seeding rate | Adjusting PLS seeding density | Estimating bulk seeding rates | Seeding systems | Seeding success | Appendix

The first step to a productive perennial forage stand is strong seedling establishment. Before the seeding equipment enters the field, several factors must be considered.

Are You Ready to Seed?

The process begins with the use of high quality seed of adapted species and varieties. Other key factors include the following:

- site selection

- seedbed preparation

- soil fertility

- seeding dates

- seeding techniques

Good management practices ensure stands will be vigorous and capable of producing high yields of pasture or hay.

Choosing the Correct Species

Identify the end use of the forage crop. Some species are better suited to hay production than for use in pasture programs (Table 1). Identify the soil type on which the forage crop will be grown. Soil pH, salinity, drainage and texture will all affect plant growth. Some forages species are able to tolerate these conditions better than others.

Soil moisture during the growing season greatly affects the growth of forage crops. Some crops are better able to withstand periods of drought or high water tables.

The stand must be persistent. Some forage crops have a longer life span than others. Short-lived species may work well in cropping rotations while longer-lived species may be necessary for problem soils or in areas that are not easy to cultivate. Winter hardiness of the species should also be considered.

| Table 1. Forage species end use |

| Forage species | Rotational grazing | Stored feed |

| Meadow bromegrass | ■ | ■ |

| Smooth bromegrass | ○ | ■ |

| Hybrid bromegrass | ■ | ■ |

| Meadow foxtail | ■ | ○ |

| Creepy red fescue | ■ | ○ |

| Tall fescue | ■ | ■ |

| Kentucky bluegrass | ■ | ○ |

| Orchard grass | ■ | ■ |

| Reed canarygrass | ○ | ■ |

| Annual ryegrass | ■ | ○ |

| Timothy | ○ | ■ |

| Crested wheatgrass | ■ | ○ |

| Intermediate wheatgrass | ○ | ■ |

| Pubescent wheatgrass | ○ | ■ |

| Russian wildrye | ■ | ○ |

| Alfalfa | ○ | ■ |

| Cicer milkvetch | ■ | ○ |

| Red clover | ○ | ■ |

| White clover | ○ | ○ |

| Alsike clover | ■ | ■ |

| Sweet clover | ○ | ■ |

| Kura clover | ■ | ○ |

| Sainfoin | ○ | ■ |

■ Highly suited to end use ○ Less suitable

Species mixtures can be simple or complex, but in most cases, a legume with one or two grass species is all that is required. Mixed stands containing 30 to 40 per cent legume can usually produce enough nitrogen for their needs and the grasses.

Forage species should be compatible with each other. Most mixtures should contain a blend of grass species that have a similar maturity and palatability. For example, intermediate wheatgrass or creeping red fescue may be more compatible mix partners for meadow bromegrass than meadow foxtail.

Broadcast seedings with no seed incorporation require forage species with good surface germination. Timothy, clovers and orchard grass are better surface germinators than most other forage species.

Field and Seedbed Preparation

With today's seeding equipment, seedbeds can vary from tilled seedbeds (Figure 1) to no-till seedbeds (Figure 2). As a result, seedbed preparation should be planned to accommodate the specific needs for each seeding site.

|

| Figure 1. Tilled seedbed. |

|

| Figure 2. Direct seeding. |

In tilled sites, the seedbed should be firm enough so that a footprint in the soil will be no deeper than 0.65 cm. Firming the soil will allow uniform, shallow coverage of the seed and prevent the seedbed from drying out.

Control weeds before you seed. In-crop control will be difficult, especially if a mixture of legumes and grasses has been seeded. Check field records and ensure that no residual herbicides have been used on previous crops.

Evaluate the amount of residue in the field. Excess trash in the drill row (hairpinning) will reduce germination. Sod from recently cultivated forage stands can keep the seedbed loose. Under dry conditions, this type of seedbed will reduce establishment success. If a field is particularly "soddy," it might be beneficial to defer seeding forages until the following year to allow further decomposition.

Inoculation of Legumes

Legumes require inoculation with rhizobia bacteria to properly fix atmospheric nitrogen. Verify that the inoculant or pre-inoculated seed you are buying has not expired and is specific for the crop to be sown. For example, red clover inoculant will not work on alfalfa. A few key points to note:

- Store inoculant or pre-inoculated seed in a cool, dark place until ready to seed.

- If the inoculant requires a sticking agent, use only the recommended commercial sticker.

- Only inoculate what can be sown in one or two days. If seeding is delayed, remove the inoculated seed from the seeder and store it in a cool, dark place.

Legume inoculants

- Alfalfa and sweet clover - Rhizobium meliloti

- Alsike, red and white clover - Rhizobium trifolii

- Birdsfoot trefoil - Rhizobium loti

- Cicer milkvetch spp (special strain)

- Kura clover - Trifolium spec 3

Seed Treatment

Consider using a fungicide when establishing forage legumes under cool damp conditions. Metalaxyl is commonly used and will protect both seed and seedlings from several fungal diseases.

Time of Seeding

Spring is the ideal time to seed forages. While the exact dates may vary throughout the province, between May 15 and June 15 is typically the best window of opportunity. Optimum soil temperatures for germination will range from 10°C to 20°C, although germination can occur as low as 5°C.

Late summer seeding is best suited to irrigation. Late seeding can be very hazardous if insects are present or if the soil is excessively dry. There must be sufficient root development before freeze-up and 6 to 8 weeks of growth is usually required.

Late fall seeding, before freeze-up, can work. For this method to be successful, the soil temperature must be below 2°C to prevent germination. This method may not be successful with alfalfa or sweetclover.

Fertility During Establishment

Fields should be soil tested before seeding forages to determine soil nutrient levels. Fertility is important to the developing seedlings, but care should be taken not to overdo it. Excessively high fertility can increase weed competition and cause cover crops to lodge.

Banding large amounts phosphate or potash into the seedbed can provide adequate nutrients for several years of forage production. For example, as indicated in Table 2, alfalfa can remove up to 16 kg/ha of phosphate for every tonne of dry matter removed.

| Table 2. Nutrient removal per tonne of hay (kg/ha) |

| Crop nutrient | Alfalfa | Grass |

| Nitrogen (N) | 66 | 38 |

| Phosphate (P205) | 16 | 12 |

| Potash (K20) | 66 | 49 |

| Sulfur (S) | 77 | 55 |

Source: Alberta Agriculture and Rural Development Forage Nutrient Use Calculator

If your goal is to produce 2 tonnes of dry matter every year for 4 years, you could apply over 100 kg/ha of phosphate to match the removal rate. While effective, this method is expensive. In areas that receive adequate moisture, phosphorus deficiencies can be corrected by broadcasting phosphate fertilizer on established stands.

Phosphate fertilizer can be mixed with forage seed to provide extra volume and density. This approach will help maintain seed flow in drill metering systems and also permit the seeding of forage species, such as Kentucky bluegrass, that have a low seeding rate.

Low rates of phosphate fertilizer, 15 kg/ha, can be placed with the seed at the time of seeding. If the seeding equipment can scatter the fertilizer over a wider area or band it separately, then higher amounts can be used.

Placing phosphorous with the seed can help the new seedling develop into a healthy plant, particularly under cool, moist conditions. Fertilizer seed mixtures should be seeded as soon as possible to avoid seed injury.

Sulfur deficiencies can be corrected by either banding or broadcasting sulphate sulfur before seeding. Although both grasses and legumes will benefit, legumes have a greater requirement for sulfur.

The use of seed placed-nitrogen should be minimal, as seedling emergence has been reduced by 30 per cent when nitrogen was applied at a rate of 30 kg/ha (Table 3).

| Table 3. Effects of seed-placed nitrogen on timothy emergence |

| Rate of nitrogen | Seedling emergence as % of check |

| kg/ha | Urea (46-0-0) | Ammonium nitrate (34-0-0) |

000 | 100 | 100 |

030 | 065 | 070 |

060 | 036 | 040 |

120 | 000 | 000 |

120* | 096 | 102 |

* Nitrogen fertilizer was broadcast and worked to a depth of 5 cm before seeding.

From: Bailey, L.D. Brandon Research Station Report.

Seed Placement

Seed placement is related to seed size, soil texture and moisture conditions. Seeding too deep can result in poor seedling emergence and is often the major reason for establishment failures. Most forage seeds are very small and do not have enough energy to emerge from deep seedings.

Under good seed bed conditions:

- Most forage species should be seeded at a depth of 1.25 to 1.90 cm.

- For small seed species such as timothy, seeding depths of 0.65 to 1.25 cm should be used.

- In sandy soil with poor moisture conditions, seeding depth may be increased, but in heavier soils, deeper seedings will greatly reduce emergence.

- Measurements for seeding depth should be taken after the press or packing wheels have passed over the seed.

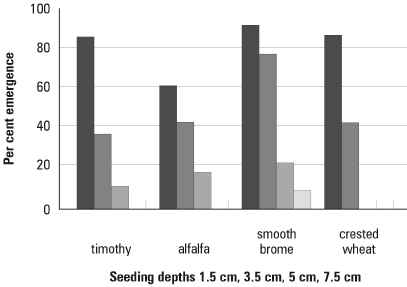

Figure 3 illustrates the effect that seeding depth has on forage seedling emergence. There are many ways to seed forages successfully. The method is not important as long as the seed is placed at the proper seeding depth, covered with soil and then packed to provide good seed-to-soil contact.

Figure 3. Percentage emergence from different seeding depths.

Adapted with permission from K.W. Clark Principles and Practices of Commercial Farming - 1997

Companion Crops

Companion crops compete for light, moisture and nutrients with forage seedlings during the establishment year. With this type of management, there is a significant risk that many forage seedlings will not survive the establishment year. In subsequent years, this reduction in forage seedling density will lead to thin stands, reduced forage yields and increased weediness.

Management decisions should focus on minimizing the affect from companion crop competition on forage seedling establishment. The following aspects can help reduce the effect of competition from companion crops:

- Only seed a companion crop if soil erosion is a concern, or it is essential that you produce a silage or green-feed crop.

- Reduce the seeding rate to less than 50 per cent of the normal rate used for grain production.

- Reduce the amount of nitrogen fertilizer applied to the companion crop.

- Use less competitive crops such as triticale, wheat, canola or early maturing oat or barley varieties and seed early.

- Do not underseed forages with low seedling vigor such as Russian wildrye, cicer milkvetch or native species.

- Remove the cover crop at the early dough stage for silage or green-feed. This removal will open up the canopy and provide more time for the forage seedlings to recover.

- If the companion crop is removed as grain, remove the straw from the field or chop and spread it. If the straw is allowed to remain in a windrow, it will smother the seedlings growing under it.

- Know what in-crop herbicides are compatible with both the forage seedlings and companion crop before seeding.

Seed Quality

Seed certification

The quality characteristics of forage seed are best determined through testing by a licensed seed analyst. Based on the test results, a certificate of analysis will be issued that provides a description of the seed, a grade, the germination rate and the amount of pure live seed, expressed as percentage of the total.

Pure live seed (PLS) refers to that portion of the seed from the designated crop that is capable of producing a plant. It is an error to assume forage seed is 100 per cent pure. Many forage species are chaffy or contain seeds from other crops, weed seeds or inert material. Foreign materials are taken into account when the PLS rating is developed for the certificate of analysis. For further information on the topic, see How to Purchase High Quality Forage Seed, Agdex FS 120/45-1.

How to determine PLS %?

If a PLS percentage is not available, use the following formula:

% PLS = (% germination x % pure seed) ÷ 100

Example:

Meadow brome with 79% germination and 95% pure seed.

(79 x 95) ÷ 100 = 75% PLS

Seeding Rate

A seeding rate is the weight or volume of seed applied to a unit of land, e.g. 15 kg/ha or 1 bu/ac. In forages, the bulk seeding rate should be based on a desired seeding density. Seeding density refers to the number of seeds placed in a meter of row or in a square meter.

For good stand establishment to occur, adequate viable seed must be placed in the seedbed. Seeding densities listed in Table 4 are based on PLS and provide adequate seed to establish a forage stand under good seeding conditions.

Using Table 4

Table 4 provides the PLS seeding density for individual forage species. The seeding densities are listed as either PLS per meter of row or per square meter.

Seeding densities should be adjusted for different soil zones. Seeding densities for the Brown or Dark Brown soil zones should be selected from the lower end of the PLS ranges. In the Black, Grey-wooded or irrigated soil zones, seeding densities should be selected from the upper end of the PLS ranges. For example, with meadow bromegrass a seeding density of 40 PLS/meter of row would be appropriate for the Dark Brown soil zone while

70 PLS/meter of row would be suitable for the Black soil zone.

PLS seeding rates for 15, 23 and 30 cm row spacings are provided in Table 4. These seeding rates are based on using the average seeding density for each species. For example, for meadow brome the average seeding density is 55 PLS/meter of row.

Adjusting PLS Seeding Density

Seed/kg - The number of seeds/kg can vary among forage species. Use the seeds/kg for individual cultivars if they are available; otherwise, use the seeds/kg rating in Table 4.

Seedbed conditions - Seed placement, germination and seedling establishment are all affected by seedbed conditions. Seeding rates should be increased when seeding into poorly prepared seedbeds or where conditions such as salinity or soil type (clay) may limit seedling survival.

1000 kernel weight - Forage species with small seeds, 0.20 to 1.0 gm/1000 kernels, often require higher seeding rates to improve seed metering and to compensate for seed that may be buried too deep for proper emergence.

Forage species with large seeds, 4.0 to 22.0 gm/1,000 kernels, may require higher seeding rates to meet the seeding densities listed in Table 4.

Seeding equipment - The seeding density should be increased by 30 to 150 per cent for broadcast seeding systems or drills without depth control. A higher seeding density is often required to compensate for poor seed placement with these seeding systems.

Moisture availability - The seeding density can be increased in irrigated areas, in high rainfall areas or where no companion crop is being used. Under these conditions, a higher seeding density will produce a more competitive forage crop during the establishment year.

Estimating Bulk Seeding Rates

The bulk seeding rate refers to the final weight or volume of forage seed that will be applied to the land

e.g. 15 kg/ha. The bulk seeding rate will reflect seed quality, germination and purity as well as any seed amendments such as seed coatings. The seeding system, broadcast or row seeding, may also influence the final quantity of seed required.

Pure stands

For pure seedings, an initial estimate of the bulk seed requirement can be obtained with the following formula:

PLS seeding rate / % PLS = kg's of pure live seed

For example, from Table 4, meadow brome seeded in 23 cm rows has a PLS seeding rate of 13 kg/ha. If the seed certificate indicates the pure live seed percentage as 75 per cent, how much bulk meadow brome seed will we need?

13 kg/ha / 75% PLS = 17.3 kg/ha

Forage mixtures

Developing a PLS seeding rate for forage mixtures requires planning. The seeding density for each species should reflect the long term needs for forage production plus the differences between species in terms of germination rate, seedling vigor and seedling competitiveness.

Forage species with good germination and seedling vigor may establish well, but they may also provide strong competition for forage species with slower germination and less seedling vigor. Competition during the establishment period may result in some species plant numbers being reduced. Simple mixtures of two to four species provide the best means to provide plant diversity and yet limit seedling competition.

The PLS seeding rates listed in Table 4 can be used to develop seeding rates for forage mixtures. For each forage species, multiply the PLS seeding rate in Table 4 by the desired percentage in the mixture. This figure will provide an estimate of the amount of PLS seed required from each species. Further adjustments to individual species seeding rates may be required considering variables such as seedbed conditions, seeding systems or management issues.

For example, based on Table 4, a pasture mix with 60 per cent meadow bromegrass and 40 per cent alfalfa seeded in 23 cm rows would require 7.8 kg/ha of meadow bromegrass (13 kg/ha x 60%) and 2.8 kg/ha of alfalfa (7 kg/ha x 40%) for a total PLS application rate of 10.6 kg/ha. This seeding rate may require further adjustments for local growing conditions or pasture management objectives.

For further assistance on developing seed mixtures, go to the "Forage Seed Mixture Calculator," which is located on Alberta Agriculture's Ropin' the Web internet web site.

| Table 4. Seeding density for pure stands |

| Grass species | PLS/meter of row | PLS/m2 | 1,000 kernel weight | Seeds/kg** | Approximate number of seeds at 1 kg/ha | Seeding rate PLS kg/ha* row spacing in cm |

| Seeding density | (grams) | (average) | m2 | ft2 | 15 | 23 | 30 |

| Bromegrass |

| Meadow | 40 - 70 | 175 - 350 | 5.22 | 191,527 | 19 | 2 | 19 | 13 | 10 |

| Smooth | 40 - 70 | 175 - 350 | 3.17 | 314,997 | 31 | 3 | 12 | 8 | 6 |

| Foxtail |

| Creeping | 150 - 200 | 600 - 900 | 0.58 | 1,732,975 | 173 | 16 | 7 | 4 | 3 |

| Meadow | 130 - 150 | 600 - 950 | 1.11 | 897,017 | 90 | 8 | 10 | 7 | 5 |

| Fescue |

| Creeping red | 90 - 120 | 400 - 550 | 1.2 | 826,447 | 83 | 8 | 8 | 7 | 4 |

| Meadow | 70 - 100 | 300 - 450 | 1.97 | 507,063 | 51 | 5 | 11 | 7 | 6 |

| Tall | 70 - 100 | 300 - 450 | 2.2 | 453,535 | 45 | 4 | 12 | 8 | 6 |

| Kentucky bluegrass | 250 - 300 | 950 - 1300 | 0.2 | 4,799,464 | 480 | 44 | 4 | 3 | 2 |

| Orchard grass | 180 - 200 | 700 - 900 | 1.06 | 941,815 | 94 | 9 | 13 | 9 | 7 |

| Reed canarygrass | 180 - 200 | 700 - 800 | 0.84 | 1,185,911 | 118 | 11 | 10 | 7 | 5 |

| Ryegrass |

| Annual – Italian | 100 - 140 | 400 - 600 | 2.09 | 478,403 | 48 | 4 | 16 | 11 | 8 |

| Perennial | 100 - 140 | 400 - 600 | 1.89 | 529,991 | 53 | 5 | 15 | 10 | 7 |

| Timothy | 150 - 225 | 650 - 1000 | 0.39 | 2,564,417 | 256 | 24 | 5 | 3 | 2 |

| Wheatgrass |

| Crested (diploid) | 30 - 60 | 130 - 260 | 1.46 | 686,079 | 69 | 6 | 4 | 3 | 2 |

| Crested (tretraploid) | 30 - 60 | 130 - 260 | 5.15 | 427,961 | 43 | 4 | 7 | 5 | 4 |

| Intermediate | 30 - 60 | 130 - 260 | 5.66 | 176,546 | 18 | 2 | 17 | 11 | 9 |

| Northern | 30 - 60 | 130 - 260 | 3.12 | 319,670 | 32 | 3 | 9 | 6 | 5 |

| Pubescent | 40 - 60 | 175 - 260 | 5.66 | 176,546 | 18 | 2 | 17 | 11 | 9 |

| Slender | 30 - 60 | 130 - 260 | 3.35 | 297,624 | 30 | 3 | 10 | 7 | 5 |

| Streambank | 30 - 60 | 130 - 260 | 2.98 | 335,103 | 34 | 3 | 9 | 5 | 6 |

| Tall | 40 - 60 | 175 - 260 | 6.02 | 166,052 | 17 | 2 | 20 | 13 | 10 |

| Western | 30 - 60 | 130 - 260 | 3.94 | 253,532 | 25 | 2 | 12 | 8 | 6 |

| Wildrye |

| Altai | 30 - 50 | 250 - 325 | 7.53 | 132,802 | 13 | 1 | 23 | 15 | 11 |

| Dahurian | 40 - 60 | 175 - 250 | 5.15 | 194,007 | 19 | 2 | 19 | 13 | 10 |

| Russian | 40 - 50 | 175 - 250 | 2.79 | 358,472 | 36 | 3 | 8 | 6 | 4 |

| Hybrid grass |

| Hybrid brome | 40 - 70 | 175 - 350 | 4.99 | 200,261 | 20 | 2 | 18 | 12 | 9 |

| Hybrid wheatgrass | 30 - 60 | 130 - 260 | 3.84 | 260,146 | 26 | 2 | 12 | 8 | 6 |

.

| Table 4. Continued |

| Legumes species | PLS/

meter of row | PLS/m2 | 1,000 kernel weight | Seeds/kg** | Approximate number of seeds at 1 kg/ha | Seeding rate PLS kg/ha* row spacing in cm |

| Seeding density | (grams) | (average) | m2 | ft2 | 15 | 23 | 30 |

| Alfalfa | 40 - 120 | 175 - 550 | 2 | 500,008 | 50 | 5 | 11 | 7 | 5 |

| Birdsfoot trefoil | 100 - 150 | 450 - 650 | 1.23 | 815,358 | 82 | 8 | 10 | 7 | 5 |

| Cicer milkvetch | 70 - 90 | 300 - 400 | 3.7 | 270,199 | 27 | 3 | 19 | 13 | 9 |

| Clover |

| Alsike | 160 | 750 | 0.67 | 1,500,025 | 150 | 14 | 7 | 5 | 4 |

| Red | 110 - 130 | 450 - 550 | 1.67 | 600,010 | 60 | 6 | 13 | 9 | 7 |

| Sweet | 80 - 120 | 350 - 550 | 1.75 | 570,027 | 57 | 6 | 12 | 8 | 6 |

| White | 160 | 750 | 0.58 | 1,710,787 | 171 | 16 | 6 | 4 | 3 |

| Kura | 70 - 80 | 400 - 450 | 1.8 | 552,258 | 55 | 5 | 9 | 6 | 5 |

| Sainfoin | 40 - 60 | 175 - 250 | 19.96 | 50,089 | 5 | 0.5 | 65 | 43 | 33 |

*PLS kg/ha: Canada Seeds Act standards are used for germination and purity in developing PLS seeding rates. All PLS seeding rates are based on bare seed.

- Bulk Seeding Rates: See the Appendix to determine bulk seeding rates.

- To convert PLS/meter to PLS/ft of row, divide by 3.28

- To convert PLS/m2 to PLS/ft2, divide by 10.80

** Data source: USDA NRCS National Plants Database

Determining bulk seeding rates

- Forage Seed Mixture Calculator. The calculator can be used to develop bulk seeding rates for grass or legume species. Seeding rates can be provided in metric or imperial measurements and for broadcast or row seeding systems.

- The Appendix to this factsheet provides examples of how to hand calculate forage seeding rates for either broadcast or row seeding systems. Information to complete the calculations is listed in Table 4 or is available on your seed certificate.

- Further information on forage seeding recommendations can also be obtained from the Alberta Ag-Info Centre at 310-FARM (3276).

Seeding Systems

Air seeding systems

Air seeders consist of an air delivery system that moves the seed from a grain tank to either a disc, knife, hoe or spoon type furrow opener for seed placement (Figure 4). Air seeders offer the advantages of being able to seed large areas in a single pass plus the ability to direct seed into either annual crop stubble or forage sod.

Figure 4. Air seeding forages.

The option to direct seed into stubble can eliminate the need for a companion crop and enhance forage seedling emergence by preserving soil moisture. To reduce the risk of seeding too deep, air seeders should be equipped with depth control devices such as gauge wheels.

Tank agitation will be required with most air seeders to prevent seed bridging. Some forage seed mixtures may also require the addition of fertilizer to ensure uniform seed flow through the metering system.

To avoid germination injury, in-row fertilizer placement should not exceed 12 kg/ha of nitrogen or 20 kg/ha of phosphorus. Fertilizers with a low nitrogen analysis like 11-55-0 should be used for tank mixing with forage seed.

Contact your equipment manufacturer to confirm if your air seeder's tank and metering system are capable of seeding forage crops.

Key points:

- Use clean forage seed to avoid tank bridging and plugging of openers.

- Reduce the airflow to the lowest setting to avoid blowing seed out of the furrow.

- Use tank agitators or mix seed with phosphate-based fertilizer for tank metering.

- Set depth control for forage seeding.

- Knife or disc openers provide the best option for seed placement.

- Seeds fields in smaller blocks (20 acres) to avoid having to re-seed larger areas if the air system fails due to tank metering or opener problems.

Direct seeding

Annual crop stubble

Direct seeding into annual crop stubble can provide several benefits for newly emerging forage seedlings (Figure 5). Standing stubble can reduce evaporation at the soil surface, prevent soil erosion, reduce soil crusting and provide some shade for the emerging seedlings. Undisturbed fields are also firm, which helps in providing depth control for seeding equipment.

|

| Figure 5. Direct seeded canola stubble. |

In annual crop stubble, straw and chaff from the preceding crop must be handled properly. The residue should either be removed by baling or by being chopped and spread as widely as possible during combining. Field harrowing after harvest can also be used to help spread straw and chaff.

Most disc, knife or hoe openers can be used in annual crop stubble to seed forages. To optimize performance, coulters should precede drill openers. Coulters can cut through crop residue and provide a better seedbed for seed-to-soil contact.

Canola or pea stubble appears to work better for direct seeding than cereal stubble because there is less crop residue and less competition from volunteer plants. Applying a glyphosate product before and/or after seeding, but before seedling emergence is a cheap and effective method of weed control.

Key Points:

- Remove annual crop straw or spread by chopping at harvest to avoid hairpinning.

- Canola or pea stubble has low levels of residue.

- Check fields for herbicide residues that may affect forage seedlings.

- Disc, knife or hoe openers with individual depth control should be used in annual crop stubble.

- Control annual or perennial weeds before seeding with non-residual and non-selective herbicides.

Sod seeding

Seeding into forage sod presents challenges. Old roots and top growth can make it difficult to obtain good seed placement (Figure 6). In addition, existing sod will compete for moisture and nutrients with the newly seeded forages resulting in inconsistent seedling establishment.

|

| Figure 6. Sod seeding. |

For these reasons, it is important to suppress the old forage stand. Spraying with a non-selective herbicide a year in advance of re-seeding will provide time for sod decomposition to occur.

Disc or narrow knife openers with cutting coulters are generally best suited for seeding into sod. Hoe openers will tear the old sod leaving a rough surface. Good in-row packing is required to ensure that the slot is closed and the seed is covered with soil.

The lack of good seedbed conditions, disease, weeds or autotoxicity often limits the immediate re-seeding of forages. The use of an annual cereal crop for the first year is often a better option than trying to re-seed a perennial forage crop.

Grasshopper control may also be required on sod seeding sites. High grasshopper populations can result in poor stand establishment. Control of grasshoppers with bait applications may be required to minimize seedling damage.

Key Points:

- Use non-selective herbicides to terminate forage fields one year in advance of re-seeding.

- Direct seed an annual crop into the old sod in the first year to improve seedbed conditions before direct seeding a new forage stand.

- Disc or knife openers are best suited to direct seeding into old sod.

- Increase forage seeding rates to 1.5 times normal if seeding into recently terminated forage sod.

For more information on sod seeding, go to Alberta Agriculture's Ropin' the Web, and select "Search" and enter "sod seeding" to obtain research articles on this topic.

Double disc drills, hoe drills

A double disc drill equipped with depth control bands, a seed agitator in the seed box or with specialized forage seed boxes is excellent for seeding forage crops (Figure 7). These drills work best in fields with light stubble cover or in fallow. Hoe drills can also be used, but control of seeding depth maybe a problem under some soil conditions. Hoe drills can be more effective in seeding through crop residue.

|

| Figure 7. Disc drill. |

Avoid placing forage seed through the same disc opener if a companion crop is being seeded. This action could result in the forage seed being placed deeper than the optimum seeding depth of 1.25 cm. If a companion crop is planned, consider seeding the annual crop as a separate pass before seeding the forage stand.

Producers have successfully used seed drills by removing the downspouts and dropping the seed in front of the disc or hoes. The discs or hoe toss the soil over most of the seed. This method requires extra packing, harrowing or rolling after seeding to ensure good seed-to-soil contact.

Downspouts have also been relocated so that forage seed falls behind the openers, and the press wheels pack the seed in the seed row. This method closely resembles the brillion type seeders

Some forage seed mixtures may require the addition of fertilizer to ensure a uniform seed flow through the metering system. To avoid germination injury, in-row fertilizer placement should not exceed 12 kg /ha of nitrogen or 20 kg/ha of phosphorus. Fertilizers with a low nitrogen analysis like 11-55-0 should be used for tank mixing with forage seed.

Key Points:

- Calibrate metering system to ensure proper forage seeding density.

- Set depth controls for forage seeding.

- Add phosphate fertilizer to improve metering.

- Use in-row packers or harrow pack after seeding.

- Increase PLS seeding density if drill lacks depth control or for poor seedbed conditions.

Broadcast systems

Traditional spinner spreaders can be used to apply forage seed, but due to differences in seed weight and size, it can be difficult to spread accurately with this equipment. Fluffier seeds such as smooth bromegrass are not flung as far as heavier seeds such as alfalfa or clover.

This discrepancy can lead to an uneven distribution of forage plants within the stand. For this reason more producers are using a dribble type of boom spreader with either air or mechanical distribution systems. Floaters, Tera-Gators and Velmars are included in these types of systems.

Accuracy of seed distribution is generally very good and may permit the application of fertilizer at the same time. Carriers such as a phosphate fertilizer are used to help with flow and to even out seed application, particularly with bromegrasses.

The field should be harrow-packed, harrowed or rolled after spreading the forage seed (Figure 8). The final operation is needed to cover the seeds with soil and to provide good seed-to-soil contact. Seeds must absorb water from the soil before they germinate. Poor soil contact can delay water absorption and result in poor germination.

Figure 8. Packing seedbed.

Brillion seeders are also utilized for seeding forage crops. These specialized seeders are equipped with two corrugated rollers, which help maintain a proper seed placement as well as provide good seed-to-soil contact. These seeders are best suited to well tilled soils. This machine leaves the soil surface very smooth. Sometimes, seedling emergence problems occur, especially on heavy clay soils, which tend to crust after heavy rains.

For broadcast seeding systems, seeding density should be increased by 30 per cent for tilled soils and 150 per cent for sites with poor seedbed conditions.

Key Points:

- Calibrate airflow or brillon systems before seeding.

- Add phosphate fertilizer to improve seed flow in airflow or brillon systems.

- Harrow or pack fields immediately after seeding.

Seeding Success

Evaluating your seeding success

Forages seeded without a cover crop can be monitored for establishment and stand density within 90 days of seeding. Those underseeded with a companion crop should be evaluated by early fall. Evaluations should also be done in the spring of the year after seeding to confirm stand density. If the number of established seedlings is too low for a successful stand, re-seeding into the existing seedbed may still be possible.

Some caution should be used in evaluating forage seedings. Drought, cover crop competition, seedbed conditions or the inherent seedling vigor of a forage species can affect seedling establishment. Under some circumstances seedling establishment may be slow.

New forage seedings are best evaluated by measuring the number of seedlings within a given area. The number of seedlings per foot of drill row or the number of seedlings within a square foot of area are common measurements. Check several locations within a field to confirm the overall seedling establishment. Uniformity of the stand across the field is as important as plant density.

Forage seedling densities for first-year stands are provided in Table 5. The seedling densities reflect good seedling establishment and can serve as a general guideline when evaluating stands. Subjective judgment is often required when deciding whether existing plant densities are adequate for a productive forage stand.

Correcting poor stand establishment:

Direct seeding with low disturbance air or no-till type drills provides the best option for re-seeding forage stands that have poor stand establishment. These seeders will provide proper seed placement while minimizing disturbance to the existing forage plants.

Direct seeding will also eliminate the cost of preparing a new seedbed. Broadcasting can also be used, but proper incorporation of the forage seed may lead to the loss of some of the existing plants.

| Table 5. Suggested seedling density (plants/m2) |

| Soil zones | Legumes | Grass/Legume (50:50) | Grass |

| Black | 80 -100 | 80 -100 | 100 -160 |

| Dark Brown | 60 -100 | 60 -100 | 100 -160 |

| Brown | 30 - 50 | 20 - 40 | 20 - 40 |

| Grey Wooded | 40 - 50 | 30 - 40 | 40 - 50 |

| Irrigation | 150 -250 | 150 - 200 | 200 - 300 |

| To convert plants/m2 to plants/ft2, divide by 10.80 |

** Seedling densities are for the first year after seeding. Plant density may decline further in following years. Seedling densities are suggested minimums to obtain a productive stand.

Source: Alberta Agriculture and Rural Development forage staff, AFSC Crop Insurance

For best results, re-seeding should occur within the year of seeding or the following spring. For some forage species, such as alfalfa, it is important to re-seed early. Established alfalfa plants can produce an effect known as autotoxicity. This phenomenon is the result of autotoxic compounds that are released from exsiting plants. The compounds restrict root development in new alfalfa seedlings. As a result, many seedlings will die or remain stunted and less productive in subsequent years.

Weed management

Weeds can jeopardize the establishment of perennial hay and pasture crops. As such, weeds should be controlled for several years before seeding the hay or pasture crop, especially the problem perennial weeds such as Canada thistle, yellow toadflax, dandelion, ox-eye daisy, common tansy, quackgrass, foxtail barley and any poisonous plants.

Pre-harvest or post-harvest glyphosate can provide long term control of many of these weeds. Pre-seeding applications of glyphosate will control annual and winter annual weeds.

Also, before seeding a perennial hay or pasture crop, it is important to check the field records for prior residual herbicide applications to avoid possible injury to the crop. Verify the crop seeding restrictions for residual herbicides in Alberta Agriculture's annual publication Crop Protection (Agdex 606-1).

When purchasing certified forage seed, producers need to ask for the seed certificate and check it for seeds of noxious weeds and weeds that are not already on the land to be seeded. This step can avoid a very costly problem in the future.

If the perennial hay and pasture crop has to be seeded into a field that is known to be weedy, certain steps should be taken:

- delay seeding

- consider using a pre-seed herbicide to control weeds

- pre-emergent herbicides may be used on some legumes to control weeds

- post-emergent herbicides are available to control weeds after emergence

- mowing weeds can also work well to control competition from weeds

Clipping weeds off just above the forage will remove the seed heads and open up the canopy for the forage seedlings.

If the volume of weeds is high, use a swather, and soon after swathing bale up and remove the clipped weeds from the field. If the swaths are left on the field, they will smother the forage seedlings. Mowing or clipping is not an option when a companion crop is seeded with the forage crop.

As annual and winter annual weeds will usually grow faster and compete with the perennial forage crop, they should be controlled or suppressed with herbicides to allow the forage to establish. Check Crop Protection (Agdex 606-1) or contact a forage specialist before using herbicides to ensure that your forages tolerate the herbicide used.

Follow label directions closely and be aware of grazing and feeding restrictions as included for each herbicide in the Crop Protection publication. There are few herbicide options for controlling broad-leaved weeds in legume stands and few herbicide options for controlling grassy weeds in grass stands. There are no herbicide options for controlling broad-leaved and grassy weeds in a legume and grass stand underseeded to canola.

Appendix

Calculating bulk seeding rates

The following are examples of how to determine a bulk seeding rate for broadcasting or row seeding. To complete the calculations, the following information will be required:

- forage species selected from Table 4

- PLS seeding density from Table 4

- germination and purity information from seed certificate

- number of seeds /m2 at a seeding rate of 1 kg/ha for selected species from Table 4

Broadcasting seeding calculations

Step 1: Select forage species and seeding density:

- Example: Meadow brome seeded at 300 PLS/m2 (Table 4)

Step 2: Determine PLS % for seed source:

- Example: Meadow brome with 79% germ and 95% purity

[79 % x 95% ÷ 100 = 75% PLS]

Step 3: Determine the bulk seeding density per m2:

- [(100 - % PLS) x desired seeding density ÷ 100 + desired seeding density = bulk seeding density]

Example: [(100 - 75%) x 300 ÷ 100 + 300 = 375 seeds/m2]

Step 4: Determine bulk seeding rate:

- From Table 4, obtain the seeds/m2 at a seeding rate of 1 kg/ha

Example: Meadow brome has a seed density of 19 seeds/m2:

[375 seeds/m2 ÷ 19 seeds/m2 = 19.75 kg/ha]

In this example, to apply 300 PLS seeds/m2, the bulk broadcast seeding rate for meadow brome would have to be 19.75 kg/ha. This seeding rate may require further adjustments for seedbed conditions or seeding systems.

Row seeding calculation

Seeding densities for row seeding are listed in Table 4 as seeds/meter of row. Seeding densities should be adjusted for growing conditions. For example, meadow brome, seeded for pasture in the Dark Brown soil zone would require 40 to 50 PLS seeds/m while in the Black soil zone, the seeding density would be 60 to 70 PLS seeds/m.

Step 1: Select forage species and seeding density:

- Example: Meadow brome seeded at 55 PLS/m of row (Table 4)

Step 2: Determine PLS % for seed source:

- Example: Meadow brome, 79% germ, 95% purity

(79% x 95% ÷ 100 = 75% PLS)

Step 3: Determine bulk seed density per m of row:

- [(100 - PLS %) x PLS seeding density ö 100 + PLS seeding density = bulk row seed requirement]

Example: Meadow brome (100 - 75% x 55 ÷ 100 + 55 = 69 seeds/m)

Step 4: Determine a bulk seeding rate by selecting a row spacing and inserting the bulk seed requirement and the seeds/m2 at 1 kg/ha:

- [Rows/m x bulk seeding rate/m ÷ seeds/m2 = bulk seeding rate kg/ha]

Table 6 provides an example of how the bulk seeding rate for meadow brome will vary with row spacing even though the seeding density remains constant. These seeding rates may require further adjustment for seedbed conditions or seeding systems.

| Table 6. Bulk seeding rate calculations |

| Row spacing | Rows/

meter |  |  | Bulk seeding rate per meter

(Step 3) |  |  |  | Seeds/m2 at 1 kg/ha (Table 4) |  |  | Bulk seeding rate kg/ ha |

| 15 cm | 6.56 | x | _____ | 69 | _____ | ÷ | _____ | 19 | _____ | = | 21.40 kg/ha |

| 23 cm | 4.37 | x | _____ | 69 | _____ | ÷ | _____ | 19 | _____ | = | 14.26 kg/ha |

| 30 cm | 3.28 | x | _____ | 69 | _____ | ÷ | _____ | 19 | _____ | = | 10.70 kg/ha |

| 36 cm | 2.81 | x | _____ | 69 | _____ | ÷ | _____ | 19 | _____ | = | 9.30 kg/ha |

| 41 cm | 2.46 | x | _____ | 69 | _____ | ÷ | _____ | 19 | _____ | = | 8.20 kg/ha |

| . |  |  |  |  |  |  |  |  |  |  |  |

For further information on forage seeding recommendations, please contact the Ag-Info Centre at 310-FARM (3276) or check the website.

Prepared by:

Specialists with Alberta Agriculture and Rural Development:

Gordon Hutton - Forage Technology Transfer Specialist

Dr. Bjorn Berg - Forage System Specialist

Henry Najda - Grass Seed and Forage Specialist

Mark Johns - Forage Specialist

Dan Cole - Weed Specialist

Calvin Yoder - Forage Specialist

Source: Agdex 120/22-3. February 2005. |

|