| | Introduction | Components of nutrient management plans | Summary

Introduction

Manure is regarded by some as a waste product, but can in fact be an extremely valuable source of many of the nutrients required for crop growth and development, including nitrogen (N), phosphorus (P), potassium (K), sulphur (S), calcium (Ca), magnesium (Mg), copper (Cu), manganese (Mn), zinc (Zn), boron (B) and iron (Fe). In addition to being a good source of nutrients, manure can also help to improve soil quality through building soil organic matter (OM), improving soil structure, and increasing water infiltration rate and soil water holding capacity.

While manure can be a valuable resource, it can also be a source of contamination of water sources. Nitrate can be a serious contaminant of groundwater sources as a result of leaching, and N and P can cause eutrophication of water bodies where both are limiting nutrients to the growth of algae. In addition, manure can also be a reservoir of a host of pathogens and parasites that can affect human and animal health (e.g., Giardia, E. Coli). Manure can adversely impact air quality, as it can be a considerable source of odour, in particular during land application.

The key to successful nutrient management (regardless of whether nutrients originate from manure or inorganic fertilizer) is to manage nutrients in order to optimize crop growth, while at the same time minimizing risk to the environment.

Why develop a Nutrient Management Plan for my operation?

An operation may adopt a nutrient management plan (NMP) for several reasons:

| 1. | To maximize the nutrient use efficiency and minimize application costs associated with manure usage. To maximize the crop’s productive potential and minimize the input costs of commercial fertilizer. |

| 2. | To address environmental issues associated with manure application and to minimize potential loss of nutrient from target application sites into sensitive areas. |

| 3. | To address legislated requirements. In Alberta, legislation focuses on Nitrate-Nitrogen and electrical conductivity (EC). |

Developing a NMP to maximize productivity or to minimize environmental impact will result in a very similar product. Though it may appear that the goals for each of these are mutually exclusive, the end result, ideally, is the same: improved manure nutrient use efficiency, reduced costs associated with manure application, minimization of nutrient losses and maximization of crop production and protection of the environment.

Components of Nutrient Management Plans

A NMP requires both site and operation-specific information, and will provide an operation with strategies to best manage their manure resource, maximize crop production potential and minimize the impact on potential environmentally sensitive areas.

A Nutrient Management Plan can be broken into the following components:

| 1. | Site or field information |

| 2. | Manure production information |

| 3. | Nutrient application plan |

| 4. | Land management plan |

| 5. | Record management |

| 6. | Alternative options |

All plans should contain some basic information about the operation such as:

- the operation’s name and address;

- the date the plan was made;

- who developed the plan (contractor or producer); and,

- the duration of plan (number of years the plan covers).

Site information

In this component, the focus is on field or site characteristics, which will be assessed to determine whether any environmental issues exist that, may impact how manure nutrients should be managed to maximize productivity and minimize losses.

Maps - Maps, when interpreted properly, can be used to evaluate the environmental risks associated with manure applications on each site or field.

A good field sketch will serve as a visual reference for the location of potentially sensitive areas within each field (e.g. water bodies, streams, wells, springs and yard sites). The sketch is also a useful tool for custom applications, which show field location, field entrances and identify any application setbacks or areas of concern.

An aerial photo provides similar information as a field sketch, but with significantly more detail and accuracy. Aerial photos are very good for identifying areas of concern within a field or on neighbouring property.

A hydrological map can help identify ground and surface water sources. The potential for nutrient contamination of groundwater, direct contamination of surface water or contamination of surface water via the ground water will depend on the depth to groundwater, soil type, presence of soil nutrients (i.e., higher concentrations of nutrients have a higher risk of nutrient loss) and the seasonal precipitation or melt.

A topographic map or site evaluation helps determine the risk of nutrient and manure runoff into water bodies or onto neighbouring property that may result from the topographic features of the field. Topographic features such as slope will impact on manure application, and may also require consideration when developing a soil sampling strategy.

Site-specific yield maps can identify low yielding areas – allowing management practices or manure applications to be modified to support high productive areas or to avoid over-application and soil nutrient build-up in where nutrient uptake and removal will be lower. Site-specific yield maps may also prove useful in devising a soil sampling strategy for a field.

Map information can also be used to determine spreadable acreage for each field. Spreadable acreage is equal to total field acreage less the area that will be unavailable due to required setbacks from water sources, bush or high-risk areas. As the NMP is developed, management practices for both the spreadable and non-spreadable acres will be created.

Cropping and manure history of the field - Cropping history helps identify potential nutrient contributions from previous crops (e.g., pulse crops) and will help determine nutrient requirements for this year’s crop. Manure application history will help identify potential hotspots in a field that should be managed differently or where manure should not be applied until nutrient concentrations decrease.

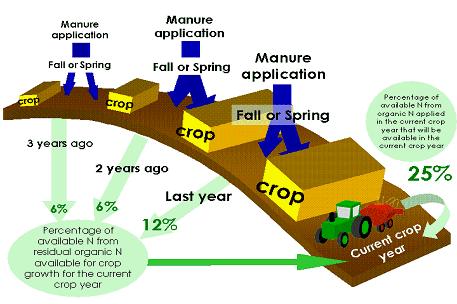

Figure 1. Residual N available from manure application in previous years for crop growth in the current crop year.

Distances between manure storage and each field will help determine application costs and calculate an economic value for the manure (based on the values of crop being grown and the soil nutrient content in that field).

Slope - Slope combined with a water source poses a potential risk for manure or nutrient runoff. By knowing the slope of a field or areas within the field which are in close proximity to sensitive areas, it can be determined if the field is appropriate for manure application or if a management practices such as injection, vegetative buffer strips or time of application be altered or adopted to lessen or eliminate potential movement of manure or nutrients into water sources.

Soil type and texture - Soil type is used to develop a realistic crop yield goal, the nutrient supplying power of the soil plus appropriate legislative regulation are designated for each soil type. Soil texture has an impact on what the appropriate land management practices are for a particular field, and is also a major factor influencing the probability that nutrients will be lost either through runoff or as a result of leaching. For instance, coarse textured soils pose a greater risk to nutrient leaching than fine textured soils, whereas fine textured soils have an increased risk of nutrient loss in runoff compared to coarse textured soils.

Identification of sensitive areas - Maps combined with observation, field history and personal experience can be used to identify sensitive areas in each field. Some examples of sensitive areas could include (but are not limited to) water bodies, wells, old yard sites, areas of significant drainage or water flow, irrigation or populated areas. Once sensitive areas are identified, management practices related to manure and nutrient application can be adopted to minimize the potential loss of nutrients.

Soil sampling and analysis - Soil sampling is the foundation of any NMP. It is the only way to determine the available nutrient status of a field and to develop field-specific fertilizer recommendations. An optimal on-farm soil testing program should include proper sampling techniques, and tests each field annually, or at a minimum every field that will receive manure in a given year.

Soil sampling frequency depends on the field’s manure history, soil nutrient level and soil type. Heavily manured land requires closer monitoring to avoid nutrient leaching and to maximize manure use efficiency.

Manure production information

Manure production information another critical component of a NMP and is needed to determine appropriate application rates and develop recommended practices for an operation/production system.

Manure is classified according to physical form, which is ultimately a result of its moisture content. The three classifications are liquid (> 90% moisture), solid-slurry (80-90% moisture) and solid (< 80% moisture).

Some of the other critical information that needs to be recorded includes livestock species, phase of production, length of manure storage, method of collection, number and size of animals determine the form, nutrient content and volume of material, which need to be applied to the land.

Published values of manure nutrient content and production rates are available for most species/classes of livestock in Alberta, but it is important to remember that these are average values. The actual nutrient content of manure on a given farm can vary greatly from book values depending on management and feeding program. As such, lab analysis of manure for nutrient content is highly recommended, and is preferred to using published averages.

Laboratories that offer manure analysis often provide a variety of tests and analysis packages. The following manure analyses are recommended:

- Moisture content or dry matter content

- Total N

- Ammonium N

- Total P

- Total K

- EC (required in Alberta)

- Optional tests: could include pH, chloride (Cl), sulphur (S), sodium (Na), calcium (Ca), magnesium (Mg) and micronutrients, such as copper (Cu), manganese (Mn), zinc (Zn) and iron (Fe)

As part of the NMP report, the manure and wastewater volumes for the operation should be calculated, if they are not known. The NMP should include the calculated or estimated nutrient availability and moisture content of the manure, and should provide the estimated crop available nutrients provided by the manure application for next four years. These nutrients should be considered when determining the nutrient application rates to supply crop production needs for each of these years.

Nutrient application plan

The purpose of the nutrient application component of the NMP is to outline the steps that producers will take to ensure that manure nutrients are placed in such a way so as to optimize crop uptake, minimize the impact of application to sensitive areas and prevent nutrients from accumulating to levels that pose a risk to the environment.

Crop nutrient requirements - Crop nutrient requirements, manure and fertilizer application rates are calculated for each field, for both the spreadable and non-spreadable areas. Crop type, yield goal and production purpose can be used to determine the expected fertility requirements for each crop in each field so as to maximize crop production. Cropping systems and rotation information are used to determine whether any nutrients from previous crop seasons will be available to support the current year’s crop requirements.

Timing and method of application - Time and method of manure application (and incorporation) must be documented and can be a major determinant of the expected proportion of nutrients that will be lost or available from applied manure. Field application losses should be factored in when calculating manure application rate, so that application still meets the targeted nutrient application goals.

Nutrient upon which application rate is based - The nutrient (N or P) upon which the application plan is based needs to be identified in the NMP. An application plan based on the nitrogen a crop needs will result in an over application of crop needed phosphorus. While an application plan based on one year’s crop P requirements will result in a significant under application of crop required N.

One recommendation is to determine manure and fertilizer application rates for at least a couple of fields based on using both N and P to compare the differences between the two strategies. A more prudent approach may be to calculate a manure application rate that provides 3-4 years of crop required P. This would provide adequate crop required N in year one but would require the application of commercial N for the remaining three years of the plan, in order to consume the P surplus in the soil.

Any NMP is subject to relevant provincial legislation. In Alberta, manure application rates are limited in the various soil zones by the soil Nitrate-Nitrogen content and depth of the water table (refer to Agricultural Operation Practices Act (AOPA)).

Once the appropriate calculations have been completed, the land application component of the NMP should document the calculated manure and fertilizer application rate (with N/P/K of supplemental fertilizer), volume of manure, number of loads of manure for each field and an estimate of the number of days of manure application per season.

Calibration of the manure application equipment - In order to apply manure with the greatest degree of precision, it is important to calibrate the manure application equipment. It is important to determine the minimum manure application rate and determine such things as required land speed, etc. to apply manure at the desired rates.

Several resources, such as the environmental beneficial management practices (BMP) manuals from Alberta Agriculture, calibration guidelines from the Tri-Provincial Manure Application and Use Guidelines, and online factsheets from several U.S. land-grant universities outline the appropriate considerations and procedures for calibrating manure application equipment. Details of the calibration procedure used should be included in the land application component of a NMP.

Land management plan

A land management plan is developed and implemented, based on field or site-specific information, to minimize the impact of manure application on sensitive areas (e.g. water sources, slopes, saline soils) within each field. In essence, this component of the NMP outlines measures the producer will take to minimize the movement of nutrients off the field after application.

There are numerous beneficial management practices (BMPs) available to producers that optimize the benefits of manure application and at the same time minimize the potential for negative impacts on the environment. Many of these are outlined in the environmental BMP manuals published by Alberta Agriculture in cooperation with Alberta commodity organizations, and are available online from Ropin’ the Web or from the Alberta Agriculture Publications Office (toll free, 1.800.292.5697).

Producers using manure and /or soil amendments should incorporate the appropriate BMPs into their farming activities in order to maintain the necessary balance between agricultural production and environmental protection.

Selected BMPs to minimize the environmental impact of manure usage - Some Selected BMP’s that can be implemented to minimize the risk of nutrient and pathogen loss to surface and ground water include:

- Developing a manure/nutrient management plan

- Adopting application setbacks from water sources or establish vegetative buffer strips and grassed waterways

- Not applying manure on course textured, highly sloped fields close to water sources

- Adjusting time and method of manure application

- Adopting direct seeding or contour tillage

- Maintaining adequate cover on the soil surface using crop residue or cover crops

- Establishing settling basins where erosion rates are high

- Establishing deep rooted crops such as alfalfa to take up nitrate that is below the root zone of other crops

- Restricting animal access to surface water

- Injecting manure

- Not applying manure to snow or snow covered ground

Producers should also consider adopting various short and long-term strategies to minimize the risks associated with high soil EC and high nutrient levels, especially on coarse textured soils. Since fields are frequently variable in character, producers should also consider strategies to address spatial differences within a field, such as varying application rates, in a field, according to spatial differences.

Compacted soils are at increased risk for nutrient losses due to runoff, particularly in areas that receive considerable precipitation. As such producers might also consider adopting strategies to reduce soil compaction during manure application, such as:

- Using drag-hose application systems for liquid manure to reduce traffic on the field

- Restricting repeated vehicle traffic to specific areas of the field (e.g. designated pathways)

- Avoiding manure application when soils are more prone to compaction (precipitation)

- Minimizing the axle weight of application equipment

While odour may not have direct environmental implications, it can have a serious impact on the social acceptance/perception of a particular operation. As such, producers may want to also consider adopt strategies to minimize odour nuisance, such as:

- Consider neighbours when agitating, cleaning pens or applying manure

- Informing neighbours in advance of agitating and applying manure

- Avoiding land application on weekends if neighbours are located downwind where odour can be a nuisance

- Injecting manure into the soil whenever possible

- Use low-level application equipment if injection is not possible and incorporating the manure as soon as possible after application

- Considering manure treatment options (e.g. composting)

- Installing windbreaks around manure collection areas and or storage facilities to disperse odour plumes

Details concerning all BMPs currently in practice on an operation and any that are planned for implementation over the course of a NMP should be included in the land management component of the plan.

Record management

Record keeping improves the producer’s ability to manage manure in a way that maximizes its economic benefit while minimizing potential environmental risk. In Alberta producers are required to keep on-farm records, these requirements are documented in the Standards and Administration Regulation of the Agricultural Operation Practices Act (AOPA). Records should be kept for all fields that receive manure, whether they are owned by the operation or leased under a manure-spreading agreement with a neighbouring producer.

Records that should be kept as a part of a NMP - Some of the records that are integral to a NMP are:

- Field identification, sketches including labels and identification of setbacks, the number of spreadable acres

- Manure production information (e.g., manure test report or published average values including as a minimum moisture content, total N, ammonium N, P, K)

- Assumptions used to develop the nutrient management plan

- Crop type, expected yield and nutrient requirements

- Amount of manure and commercial fertilizer applied, by field

- Manure application date, method and custom applicator information, by field

It is also suggested that you maintain records on:

- Weather conditions during and immediately after application

- Information on application equipment performance and calibration procedures.

Producers that transfer control of manure to, or receive manure from other operations may be required to keep additional records in accordance with AOPA.

Alternative options

If manure volumes exceed agronomic application rates based on the current cropping system or an operation’s land base is too small for the amount of manure being produced, strategies should be developed with the producer to address the manure management concerns. These might include selected feeding strategies to alter the nutrient composition of manure, manure processing strategies (e.g., composting) or other strategies designed to prevent nutrient build-up on the operation’s land base.

Summary

In summary, below is a concise checklist of the key information that should be part of any basic nutrient management plan.

| 1. | Site/Field Information

- Field information

- Farmstead sketch

- Maps (e.g. topography, hydrology, hydrogeology)

- Soil tests by fields

- Identify sensitive areas, such as water bodies, steep slopes, saline areas, groundwater within 4m of surface, coarse textured soil

|

| 2. | Manure Production information

- Animal types, phases of production, and length of confinement for each type at this site

- Animal count and average weight for each phase of production on this site

- Calculated manure and wastewater volumes for this site

- Manure storage type, period and volume

- Measured or calculated nutrient concentration of the manure (i.e., N/P/K/S and moisture)

|

| 3. | Nutrient Application Plan

- Cropping system (e.g. crop rotation, “minimum tillage”, straw removal)

- Crop types, realistic yield targets, and expected nutrient uptake amounts for N, P, K, S

- Application equipment descriptions and methods of application

- Expected application seasons and estimated days of application per season per field

- Calculated application amounts per acre per field with consideration of relevant legislation.

- If using manure, determine what nutrient (N, P) to base the application rates (your choice will affect land requirement, nutrients build-up in soil, …etc)

- Calculated amount of manure and/or fertilizer required to supply the acres available

|

| 4. | Land Management Plan

- Details of conservation practices and the practices that minimize nutrient losses and protect sensitive areas based on site information, identified sensitive areas, and manure application plan, with consideration of relevant legislation

- Short term and long term implications for phosphate, EC, and SAR

|

| 5. | Records Management

- Field identification, sketches including labels and identification of setbacks, the number of spreadable acres

- Manure production information (e.g., manure test report or published average values including as a minimum moisture content, total N, ammonium N, P, K)

- Assumptions used to develop the nutrient management plan

- Crop type, expected yield and nutrient requirements

- Amount of manure and commercial fertilizer applied, by field

- Manure application date, method and custom applicator information, by field

|

| 6. | Alternative Options

- Details regarding feeding, manure handling or processing strategies designed to help the operation cope with land resource constraints

|

Trevor Wallace

Environmental Stewardship Division, Alberta Agriculture and Forestry, Leduc, AB

Tel: (780) 980-7587

Email: trevor.wallace@gov.ab.ca |

|