| | Introduction | Bailey's and Lucas Mill | Baker Sawmills | Double Cut Sawmills | Jonsered | Mahoe Sawmills | Peterson Portable Sawmills | Select Sawmill Co | Timber Harvester | Wood - Mizer

Introduction

Specifications and detailed information on types of sawmills available to landowners intersted in small scale sawmilling. It is not the Woodlot Extension Program's intention to promote one company or another, rather show the range of possibilities available. To read about Choosing a Sawmill follow the link.

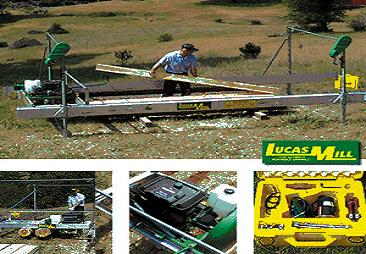

Bailey's and Lucas Mill

All of us at Bailey’s and Lucas International want to thank you for your interest in the Lucas Portable Sawmill. We are confident you will find the Lucas Mill a truly amazing machine and an exceptional value. The Lucas Mill is well thought out and has many features which make it unique. Its patented leveling design along with swing blade technology gives you the sawing capability, versatility and production you're looking for. Owners tell us of sawing 5,000 bdft. or more per day. Now that’s payback in a portable mill! We’ll show you how easy it is to set up, and how you can mill without rolling logs to get perfectly square-edged lumber. We’ll demonstrate the advantages of sawing multiple logs, large logs, timbers and ease of sharpening. The Lucas Mill is built using the best in materials and workmanship and is backed by a two-year warranty. We also have the technical expertise and a complete parts inventory so you can buy with total confidence. Just give one of our Lucas Mill Specialists and they’ll answer any questions you may have.

Easy Set Up and Take Down! The Lucas Mill sets up in about 10 minutes. Its patented design allows you to set up on uneven ground and directly over logs. This is a great feature when moving or skidding large logs that are virtually impossible to move. You can also roll logs between the end frames if need be without rolling them over rails or up on log carriages. To set the mill up you don’t need any levels or other tools to carry with you. Everything just snaps, clips or sets in place and the carriage can be wheeled over the rails and simply cranked up into position. It doesn’t get any easier than this.

Unmatched Portability! The Lucas Mill is truly the ultimate in portability. It can be carried and wheeled by one person into position. An entire Lucas Mill can be transported in a standard pick-up that is equipped with racking and can go anywhere your pick-up can go. That’s a real advantage because there isn’t any towing or backing trailers around in tight places. The Lucas mill has been loaded on boats, carried by helicopters, and hauled by horses to mill logs right where they fell. From the jungles of Africa to the mountains of New Zealand and all over the world, the Lucas Mill has been there. Now that’s portability!

LM 830K

Lucas Model 827 Portable Saw Mill

Specifications:

- 30hp V-Twin OHV Kohler Engine

- Electric Start (Battery Included)

- 21" Dia. 5 Tooth Carbide-Tipped Blade.

- 3/16" Saw Kerf. Accuracy 1/16"

- Tach & Hour Meter

- 23 V-Belt Clutch Powertrain Drive

- Mills Logs up to 54" in Dia., 20 ft. Lg.

- Mills Logs Any Size in Dia. 16-1/2" Lg.

- Mills Logs Apprx. 40 ft. With Extra Tracks

- Will Cut up to 8" x 8" Cants

- 8-1/8" x 17" Cants By Turning Powerhead

- Cuts 8-1/2" x 60" Slabs, w/Slabbing Attach.

- Cuts 7" Bevel Siding w/Bevel Attachment

Package Deal Includes:

- Sidewinding attachment

- Engine & Saw Carriage

- Swing Blade Sawing System

- 2 - Sets of End Frames

- 2 - 19 ft. 4 in. Tracks

- 2 - 4 ft. Track Extension Kits

- Center Stabilizer & Hold Down Spikes

- Extra Gas Filled Strut

- 3 - Carbide Tipped Saw Blades

- 12 Volt Diamond Wheel Grinder

- Tool Kit & High Impact Carrying Case

- 2 - Year Warranty (Engine and Mill)

LM 618B

Lucas Model 618 Portable Saw Mill

Specifications:

- 18hp Briggs & Stratton Vanguard Engine

- Electric Start & Manual Recoil

- 17" Dia. 5 Tooth Carbide-Tipped Blade.

- 3/16" Saw Kerf. Accuracy 1/16"

- Tach & Hour Meter

- 3 V-Belt Clutch Powertrain Drive

- Mills Logs up to 54" in Dia., 20 ft. Lg.

- Mills Logs over 8 ft. in Dia. 16-1/2" Lg.

- Mills Logs Apprx. 40 ft. With Extra Tracks

- Will Cut up to 6" x 6" Cants

- 6" x 12-1/2" Cants By Turning Powerhead

- Cuts 6-1/4" x 50" Slabs, w/Slabbing Attach.

- Cuts 5" Bevel Siding w/Bevel Attachment

Package Deal Includes:

- Engine & Saw Carriage

- Swing Blade Sawing System

- 2 - Sets of End Frames & Braces

- 2 - 19 ft. 4 in. Tracks

- 2 - 4 ft. Track Extension Kits

- Center Stabilizer & Hold Down Spikes

- Extra Gas Filled Strut

- 3 - Carbide Tipped Saw Blades

- 12 Volt Diamond Wheel Grinder

- Tool Kit & High Impact Carrying Case

- 2 - Year Warranty (Engine and Mill)

LM 613H

Lucas Model 613 Portable Saw Mill

Specifications:

- 13hp Honda OHV Gas Engine

- Manual Recoil Start

- 17" Dia. 5 Tooth Carbide-Tipped Blade.

- 2 V-belt Drive System

- 3/16" Saw Kerf. Accuracy 1/16"

- Mills Logs up to 54" in Dia., 14-1/2" ft. Lg.

- Mills Logs up to 20 ft. Long w/Extension Kit

- Will Cut up to 6" x 6" Cants

- 6" x 12" Cants by Turning Powerhead

Package Deal Includes:

- Engine & Saw Carriage

- Swing Blade Sawing System

- 2 - Sets of End Frames & Braces

- 2 - 19 ft. 4 in. Tracks

- 2 - Hold Down Spikes

- Extra Gas Filled Strut

- 2 - 17" Carbide-Tipped Saw Blades

- 12 Volt Diamond Wheel Grinder

- 2 - Year Warranty (Engine and Mill)

Baileys Online

Baker Sawmills

Baker Products is the premier manufacturer of pallet manufacturing equipment and portable band sawmills in the wood industry. From our original "C" Model Band Resaw to scragg mills, cut off systems and more, we cover all angles of your wood processing needs

When it comes to portable band sawmills, Baker Products has established a name in the industry for building heavy-duty, high production sawmills. We offer the economical sawmills including the 18M and 18HD Manual Bandmills with trailer packages, our fully hydraulic, high production 3638D Portable Band Sawmill and 3630E Stationary Band Sawmill, our higher production 3667D Blue Streak Portable Band Sawmill and our industrial production 3650E Super Streak Stationary Band Sawmill.

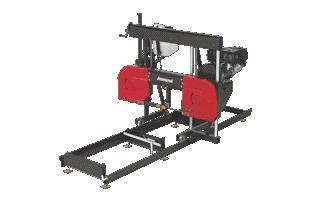

Baker 18M Band Sawmill

Overview - for ease, affordability and portability, you can't beat the Baker 18M Band Sawmill. This mill is a

manually operated mill with a removable trailer package to assist in transportation.

To saw, simply set your blade height with the hand crank, push the carriage down the length of the log, clear the blade and pull the carriage back to the front. Convert your logs into lumber and squares easily and affordably with a Baker 18M.

Highlights

- Powered by a 20 HP Honda gasoline engine (standard)

- 18" diameter band wheels

- Designed to saw logs up to 30" diameter x 16'6" long

- Roller-style blade guides

- Thin-kerf technology results in little waste and more material recovery

- Mechanical spring tensioning

- Four post carriage design

- Easy-to-read, vertically-mounted blade height indicator

- Head is raised via hand crank with chain and sprockets

- Trailer package with lights and removable single axle

- Track is made of heavy-duty 2" x 4" tubular steel

- Carriage movement through log requires +/- 10 lbs pressure

- Heavy-duty log clamps

- Heavy-duty log ramps available-for easy log loading

- Simple design makes it easy to operate and maintain

- Track extensions available at the time of order

- Baker 18HD Band Sawmill

Baker 18HD Portable Band Sawmill

Overview - our top of the line manual mill. An upgraded version of the 18M, the 18HD has a permanent trailer package to get you where you're going with ease. Named "HD" for "heavy-duty", this mill offers sturdier 2" x 6" tubular steel for its frame. The 18HD also comes with drop-down legs for easier setup and leveling. The cutting length on the 18HD has been extended from 16'6" to 20'6", allowing you to cut longer logs for longer lumber. The Baker 18HD Portable Band Sawmill provides you with more mill for your money.

Highlights

- Powered by a 20 HP Honda gasoline engine (standard)

- 18" diameter band wheels

- Designed to saw logs up to 30" diameter x 20'6" long

- Roller-style blade guides

- Thin-kerf technology results in little waste and more material recovery

- Mechanical spring tensioning

- Four post carriage design

- Easy-to-read, vertically-mounted blade height indicator

- Head is raised via hand crank with chain and sprockets

- Trailer package with lights and single axle

- Track is made of heavy-duty 2" x 6" tubular steel

- Carriage movement through log requires +/- 10 lbs. pressure

- Heavy-duty log clamps

- Simple design makes it easy to operate and maintain

Baker Wood Buddy Band Sawmill

Overview - for the hobby sawyer that needs to turn logs into lumber simply and economically, we have developed the Baker Wood Buddy Portable Band Sawmill. The Wood Buddy requires no assembly, which makes setting it up a snap. It's available with a gas motor for portability. Custom cut your own lumber, when you need it, for the right price with the Baker Wood Buddy Portable Band Sawmill.

Highlights

- 18” diameter band wheels

- Designed to cut logs up to 18” diameter x 11’ long (standard)

- Track extensions available for longer logs

- Thin-kerf technology results in little waste and more material recovery

- Economical to ship at 4' x 5'

- Lumber scale for 4/4, 5/4, 6/4 and 8/4

- Easy log clamping system

- Baker’s Exclusive Flat Guide System

- Inexpensive, starting at ONLY $3,250.00 USD!

Baker Stationary Band Sawmill

Overview - sawmilling is now faster than ever with the Baker Band Sawmill. Using a complete hydraulic system, the log can be handled quicker and smoother. The head frame is raised and lowered by a single hydraulic cylinder for more precise control of blade height setting. A round measurement dial makes blade height setting visibly easier to read. A new hydraulically-powered chain-style log turner provides more positive rotation. Saw carriage movement is dual-chain driven for more stability during the sawing process. The Baker Band Sawmill can be powered by a standard 38 HP (28 kw) Kubota diesel engine or a 30 HP (22 kw) electric motor. The Baker Band Sawmill is also available in stationary models.

Highlights

- Choice of two power sources: Diesel or electric

- 12” X 32” throat provides clear line of sight

- Larger 28” diameter all-metal band wheels

- Full 36” cutting capacity (cuts 31” thru center)

- Dual chain-driven carriage

- 16’ and 24’ capacity models

- Easy-to-read round measurement dial

- Improved bunk spacing for all log lengths

- Head is raised by quick yet accurate hydraulic cylinder

- Variable-speed drive

- Moveable guide on barky side

- Operator’s station features all controls in one convenient spot

- New and improved fence arms

- Board drag-back

- Improved leveling system for quicker setup time and breakdown

- Improved log loading arms that fold away for easy transport

- Blade enters clean wood after 1st rotation

- Stationary models available

- Optional computer setworks

- Optional debarker attachment

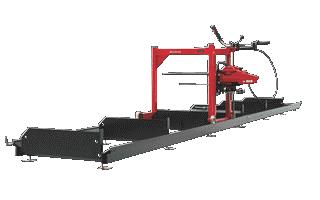

Baker Portable Band Sawmill

Overview - sawmilling is now faster than ever with the Baker Band Sawmill. Using a complete hydraulic system, the log can be handled quicker and smoother. The head frame is raised and lowered by a single hydraulic cylinder for more precise control of blade height setting. A round measurement dial makes blade height setting visibly easier to read. A new hydraulically-powered chain-style log turner provides more positive rotation. Saw carriage movement is dual-chain driven for more stability during the sawing process. The Baker Band Sawmill can be powered by a standard 38 HP (28 kw) Kubota diesel engine or a 30 HP (22 kw) electric motor. The Baker Band Sawmill is also available in stationary models.

Highlights

- Choice of two power sources: Diesel or electric

- 12” X 32” throat provides clear line of sight

- Larger 28” diameter all-metal band wheels

- Full 36” cutting capacity (cuts 31” thru center)

- Dual chain-driven carriage

- 16’ and 24’ capacity models

- Easy-to-read round measurement dial

- Improved bunk spacing for all log lengths

- Head is raised by quick yet accurate hydraulic cylinder

- Variable-speed drive

- Moveable guide on barky side

- Operator’s station features all controls in one convenient spot

- New and improved fence arms

- Board drag-back

- Improved leveling system for quicker setup time and breakdown

- Improved log loading arms that fold away for easy transport

- Blade enters clean wood after 1st rotation

- Stationary models available

- Optional computer setworks

- Optional debarker attachment

Baker Blue StreakTM Portable Band Sawmill

Overview - the Model 3667D Baker Blue StreakTM Portable Band Sawmill was built to handle big logs and big jobs. We took our extremely popular Model 3638D sawmill and beefed it up with a 2-inch band blade and a 67-HP diesel engine. No other sawmill comes close to the versatility, ease of use, production, and heavy-duty smart design of the Baker Blue Streak Sawmill. There are other improvements, as well, such as the fuel tank being larger and more conveniently located between the bunks at the front of the mill. The head is now even more stable, raised and lowered on both sides at the same time with computer-controlled rack and pinion components. The throat height capacity has been expanded from 9-1/2" to 12" between the blade and the top of the throat. You'll not find a better one-man band sawmill on the market.

Highlights

- Choice of two power sources: 67-HP diesel or 30-HP electric motor

- 12” X 24” throat provides improved clear line of sight

- Larger 28” diameter all-metal band wheels

- Full 36” cutting capacity (cuts 28” thru center)

- Dual chain-driven carriage

- 16’ and 24’ capacity models

- Easy-to-read round measurement dial

- 2-inch, 1-1/2", or 1-1/4" band blade

- Improved bunk spacing for all log lengths

- Head is raised and lowered equally on both sides with computer-controlled rack and pinion

- Variable-speed drive

- Moveable guide

- Operator’s station features all controls in one convenient spot

- Hydraulic log loader, log turner, clamps, and toe rollers

- Board drag-back

- Fast and easy set up.

- Blade enters clean wood after first rotation

- 23-1/2" gallon fuel tank conveniently located between bunks in frame

- Stationary models available

- Optional Baker CoreSetTM computer setworks

- Optional debarker attachment

Baker 3650E Band Sawmill

Overview - the Model 3650E Baker Super Streak Stationary Band Sawmill is an industrial band mill that offers the same super quality and accuracy found in all Baker equipment. The new Model 3650E Baker Super Streak Stationary Band Sawmill offers super power with a 50 HP electric engine. It is also super heavy duty, weighing in at 9,500 pounds and running a 2" band blade on two 36" diameter band wheels. Computer setworks use a servo motor, so they're super fast and yet still super accurate, setting to within 1/10,000". The Model 3650E Baker Super Streak Stationary Band Sawmill offers super versatility by giving you the option of 2-way off bearing for your sawn materials. The operator control station is a remote console chair and offers super easy to use joystick control for all sawing and log handling functions. This mill provides you with all of this super technology at a super price!

Highlights

- 50 HP Electric Motor

- Large 36" Diameter All-Metal Band Wheels

- 21' Log Capacity

- Remote Operator's Station

- User Activated Board Drag-Back

- Four Hydraulic Fence Arms

- Easy Maintenance Access

- Baker Computer Setworks Standard

- Cut Material Can Be Pulled To The End Or Slid Off The Side

Baker Online

Syncro Saw

This uniquely designed mill runs with a 27hp Kohler V-Twin gas engine. The saws are fixed like the twin saw model to each other. Standard equipment on this mill is power feed and board return however any features/options available for the twin saw mills such as electric lift, log turner, trailer package and tandem axel can be added to the Syncro Saw. This enables the customer to custom order the Syncro sawmill to fit their needs.

The Syncro Saw also has the ability to cut boards or 12” cants by flattening off 2 sides of the log to 12” and turning up the log and then removing the head saw and double cutting the 2 sided logs horizontally going down 1 side and back on the other. This mill can handle a 24” diameter log up to 16’6’’ long. To cut longer lengths extra track extensions are available.

Syncro saw diesel model - works principly the same way as the gas model, but with diesel power, which gains 20% more torque and 25% better fuel economy. The other change is the cut goes to 6x10 on the saws. The trailer and the log turner are standard.

Specifications:

- 6x8 cut (6” on the edger saw and 8” on the head saw)

- Board return (lumber is returned to back of mill with carriage)

- Optional electric 20hp motor

- Built in edger

- Blades sharpened on the mill

- Weight 1000lbs

- Optional trailer package available

D&L's small log scrag - the production rates range up to 1000 to 2000bdft and hour when cutting cants. 2 sided cants will double production.

The saws set hydraulically for fast easy productive operation. It takes 3 men to run this mill and a loader. Logs are loaded on to the infeed deck and are passed through the 2 saws producing a 2 sided cant. This cant is then pushed off the right hand side of the mill and once the deck of logs are cut they then can be returned to the live deck to be passed through again to produce you square. This mill can be used in conjunction with a bull edger to produce dimensional lumber. After 2 siding the cants they then can be put through the bull edger for high production dimensional lumber cutting or cants up to 6”

Specifications:

- 14” log diameter

- 12’ log length

- 36 “saws for a 15 “max cut

- Inserted saws

- Saws adjust from 4” to 10” hydraulically( sets infinitely )

- Variable feed chain

- Pto driven

- 8 fully hydraulic functions on the mill

- tandem axel

- Auto alignment v – trough [for the logs entering into the saw]

- Live in feed 2 – strand 15ft long

- Optional out feed 2 – strand [$ 3995.00] canadian

- Sawdust and slab conveyor under the saws

- Right or left exiting of the out feed for the cants

- Diamond sharpening system

- Bit wrench

Optional 100h.p diesel John Deere or electric 3 phase motor with built in fuel tank and skid mounted, belt adjustment tensioner system, canopy

Twin Saw Models

T.S. 30D will handle logs 6ft to 20ft long by 30in. diameter. The T.S. 48D will handle bigger logs, 6ft to 20ft long by 48in. diameter. And the T.S 60D will handle 60” diameter logs x 20ft long.

Our mills come with thin Kerf carbide tip circular saws. OPTIONAL inserted tooth blades are available. These saws can be sharpened on the mill in only a few minutes as there are only a maximum of 14 teeth in both saws. The T.S 60D has 18 teeth Each saw will cut on average between 30000 to 50000 BD FT. (depending on how clean the logs are). Saw blades usually only need sharpening every 3000 to 3500 bdft. (In 2” lumber).

These models also have the ability to saw more than one log at a time with the optional log dogs. This dogging system allows the mill to cut down to a 1 ½ “ slab. 2” slab on the T.S. 60D.

The mill’s power feed pushes the carriage through the cut. The operator has total control at all times. These mills are designed so that everything is traveling away from the operator creating a very safe work environment. The board returns as the carriage returns back to the operator for the next cut where they can be piled. The Twin Saws also comes with trailer package, built in edger sharpening equipment .

The new T.S 60D is powered with a 60 h.p diesel has 30” head saw and a 23” edger producing a 8x12 cut. This mill comes standard with all the bells and whistles full hydraulics ,log turner , hydraulic feed, inserted saws , tandem axel, heavy duty 2x11” frame , hydraulic lift on the power head, and more. The frame construction is 11/2 to 2 times larger than the T.S. 48D.

Specifications:

- No wavy cuts, very smooth texture

- Board return

- Accurate to +1 1/16

Production rates:

- T.S. 30D up to 400+ BDFT per hour(depends on log size and dimesion being sawed)

- T.S. 48D up to 800+ BDFT per hour (depends on log size and dimension being sawed)

- T.S. 60D up to 1200+BDFT per hour(depends on log and dimension being sawed)

EcoSaw hydrostatic

The EcoSaw Professional Sawmill is an all-terrain hand-portable sawmill designed to cut logs where they fall.

Extensive use in Papua New Guinea shows the EcoSaw is the only truly hand portable sawmill that can be consistently hand carried from log to log within the forest or jungle without difficulty. Less portable sawmills lead to clear felling as they cannot be carried with the ease of the EcoSaw.

The EcoSaw can also be used in a stationary position and logs simply rolled or loaded under the rails one after the other. There is no need to move the end frames or dismantle any part of the sawmill to do this. Simply wind up the saw ready for the next log. There is no frame on the ground that will be distorted by the log or require removal to load the next log.

The EcoSaw is a low cost investment specifically designed for small operators. It can be easily transported by utility or trailer, and can be carried to the log, reducing environmental damage.

The EcoSaw Professional Sawmill includes as standard: 18hp engine; all safety features; heavy duty end frames and rails; a comprehensive User Manual; and basic tools and spares.

Key benefits - Only the EcoSaw can be termed a true ecological sawmill because it can be carried with ease and set up on all types of terrain. The EcoSaw is the only true all-terrain portable sawmill on the market.

The EcoSaw is capable of a production rate of 1m3/hour of sawn timber using around 20 litres of fuel a day. The ability to select a cut to follow taper, dodge faults and avoid imperfections is unique to the EcoSaw.

The EcoSaw is arguably the safest portable circular sawmill in the world. The three unique features of the EcoSaw that make it so different to other portable sawmills are: 180° blade swing; parallelogram frame; and independent leg levelling, allowing unmatched speed of set up and versatility when cutting with the EcoSaw. Accurate cuts can be made with a deviation of ± 1mm with the capacity to cut boards from 5mm x 5mm up to 200mm x 400mm.

How it works - A circular saw blade is used to make a horizontal cut along the log followed by a vertical cut coming back in the opposite direction. The saw blade is swung by a hand lever into a horizontal or vertical position at either end of the log. The timber is cut to size as you proceed through the log. .

The EcoSaw offers the only truly independent horizontal and vertical end frame adjustment without the need to re-establish or reposition the frames. This allows the saw to be aligned with the log from the first cut, or at any stage in the cutting process, thereby providing maximum recovery. The ability to select a cut to follow the taper, dodge faults, avoid imperfections and choose your best and longest grains is unique to the EcoSaw.

No major on-site preparation is required as the EcoSaw comes with four adjustable screw out feet that allow levelling of the sawmill in under one minute. Being a portable mill, we realised the huge benefit of not having large bars to level on uneven ground. Our independent leg wind down system can be parallel in less than a minute.

Specifications:

- 8" professional hydrostatic driven model( can cut a 8x16 beam with no log turning)

- Ecosaw slabbing attachment ( for cutting slabs or timbers)( use your chain saw)

- Ecosaw sanding kit ( sanding of dry slabs)

- Comprehensive tool kit

- Ecosaw log rollers

- Blade sharpener

- Blades: 8 tooth tungsten carbide saws, 6 tooth tungsten carbide saws, 4 tooth tungsten carbide saws, 4 and 6 tooth Inserted tooth blades also available, Bit wrench

Cutting features - The EcoSaw offers you a distinctly individual choice of cutting options with a capacity to cut boards from 5mm x 5mm up to 200mm x 400mm. The EcoSaw can cut from both sides of the log for boards up to 400mm wide. With the ease of this double cutting, we turn our normal 200mm cut into 400mm in seconds. This enables the EcoSaw to cut beams or boards up to 6.4m long, 400mm wide and 200mm deep. Logs up to 2m in diameter can be easily handled.

The EcoSaw offers the ability to cut to the taper of the log in all directions allowing a higher recovery of quality timber.

The EcoSaw offers the ability to cut angles between horizontal and vertical.

Safety features - The machine is operated from outside the frames. This keeps the operator outside the "line of fire' if objects are ejected from the saw blade. Should the operator stumble, or a cupped blade kick back, it is nearly impossible to come into contact with the blade. Australian standards state a person is not allowed to work between the fixed and transversing parts of a machine where there is a risk to health and safety. No other portable mill offers you double sided riving knives, double sided blade guards or our unique deflector block. Our unique design lets you safely operate away from the blade with all these extra benefits.

All mills are covered with a 6 month warranty on a return to sales depot basis. Engines carry their own manufacturers warranties. Warranties will not cover belts, chains or circular saws, or, if the sawmill has been altered, modified or changed in any way.

WE RESERVE THE RIGHT TO CONTINUE IMPROVEMENTS TO ALL MODELS NOW AND IN THE FUTURE.

Doublecut Sawmills Doublecut Sawmills

Jonsered

Jonsered SM 2196

Jonsered’s powerful bandsaw mill is equipped with an extremely reliable four-stroke engine from Honda. The engine produces a massive 13 horsepower. The sawmill is based on a new concept whereby the bandsaw is started and stopped with a combined clutch and brake. The sawmill’s design gives you full control, as you work from the right-hand side allowing the shavings to be discarded to the left. The bandsaw also cuts faster and produces a narrower cut than a saw chain, which means less waste, greater efficiency and a better yield. The sawmill can handle sizeable logs – up to 70 cm in diameter – and offers a very high capacity. Because of its high capacity, the bandsaw mill is the perfect choice where several forest owners wish to make a joint investment in a sawmill or for those who work under contract to others. This sawmill can be supplied complete with a fully-automatic grinding machine for the bandsaw blades.

| Specifications |

| Power | 9.6 kW / 13 hp |

| Cutting width | 50 cm |

| Cutting length | 5.2m |

| Log diameter | 70 cm |

| Rail length | 2x3m |

| Rail section weight | 2x58 kg |

| Weight | 184 kg |

Jonsered SM 126

Jonsered's most mobile sawmill, complete with Jonsered CS 2186, our largest chainsaw, that you can also use as a normal chainsaw. You will find a chain sawmill is highly practical if you want to cut your timber yourself. In addition, the lightweight chain sawmill is easy to transport. The rail sections are 3 metres long and can be extended as much as you like. Max. log diameter 50 cm. You will find a chain sawmill is highly practical if you want to cut your timber yourself. In addition, the lightweight chain sawmill is easy to transport. The rail sections are 3 metres long and can be extended as much as you like. Max. log diameter 50 cm.

| Specifications |

| Power | 4.5 kW / 6.1 hp |

| Cutting width | 50 cm |

| Cutting length | 5.2m |

| Log diameter | 50 cm |

| Carriage weight | 50 kg |

| Rail length | 2x3m |

| Rail section weight | 2x58 kg |

Jonsered

Mahoe Sawmills

Mahoe Sawmills MINIMAX

The new Mahoe Minimax has been a year in development. With the new beam (patent pending) to work around, we have added lightness, strength and economy to our range of portable sawmills.

Maintenance.This is kept to a minimum with the Minimax. Sharpening is done on site with a jockey grinder. The mill is supplied with weld on tipped blades with 5mm kerf. The finish on the Mahoe cut timber is very smooth. With a history of cutting the high value Kauri, the Bergman brothers, who design and own Mahoe, know what is important in the design of a sawmill to get the most out of your resource.

Specifications:

| Motor: | Daihatsu 32H.P. Industrial Petrol

(Turbo Diesel option available) |

| Transmission: | Through V Belts |

| Rise and Fall: | Chain Blocks |

| Carriage Travel: | Friction through reduction box |

| Blades: | Saw Size, 26 inch vertical, 18 inch horizontal |

| Set-up: | 30 minutes for one man |

| Sawn Size: | 250mm x 150mm maximum |

| Log Size: | 1.5 metre diameter, 6 meter length |

| Production: | 4-6 cubic meters in 8 hours |

| Tools: | Necessary spanners |

| Training: | On request |

Safety. The safety features are all built into the Minimax. You are not working near the blades, there is a 2 riving knives and you are not doing the hard work of pushing, pulling or lifting. The Minimax appealed to farmers, sawmillers and was applauded by couples that worked together. This machine is not like running a marathon, you can production cut timber all day with the machine doing the work

Mahoe Sawmills SUPER MILL

The Super Mill is our fully hydraulic contractors mill. It is portable on its own trailer and is easily set up by two men. The latest Super Mill has seen a few different motors over the years. The biggest single part of the sawmill is the motor, so a lot of effort is made in sourcing the best motor for the job. The Super Mill is fully hydraulic with hydraulic rise and fall and hydraulic feed. Attachments to compliment the Super Mill include a Breast Bench and Hydraulic Log Dogs. Some Super Mills are cuttng oversized logs for big samills or cutting flitches to be processed by a band saw. Other operators work on contract cutting for farmers and woodcut owners or supply timber yards. These mills are used by serious portable sawmillers

Specifications

| Motor: | 83 Detroit diesel, turbo |

| Transmission: | Through 3VX powerband V belts

Horizontal saw driven by right angle gear box |

| Rise and Fall: | Hydraulic rams with locking clamps |

| Carriage Travel: | Hydraulic winch |

| Cutting: | Twins horizontal and vertical blades |

| Blades: | Style B inserted tooth

Saw size, 30 inch vertical, 16 inch horizontal or 22" |

| Blade Sharpening: | Jockey grinder supplied |

| Transportable: | On heavy duty axle and wheels -

suspension and brakes extra |

| Set-up: | I hour for two men |

| Sawn Size: | 300 mm x 150 mm or 12" x 6" |

| Log Size: | 1.5 m diameter, 6 m length - 7.5 m option |

| Production: | 15 cubic meters 2 men in 8 hours in good conditions |

| Tools: | Contains necessary spanners, level, jockey grinder, 1 style B wrench and 2 tailing out rollers |

| Training: | On request |

The Automated 2000

Is designed to cut smaller logs up to 900mm in diameter. With the Detroit 83hp diesel turbo charged motor, it has all the power needed for the computer setworks and timber removal, sawdust removal and slab wood removal. This machine has all the features. The twin saw reduces timber handling as every board cut is a finished board. The Automated 2000's are cutting for timber yards, export markets and plantation owners wanting to get the most from their trees rather than selling the trees on the stump.

Specifications

| Motor | 83 Detroit diesel, turbo |

| Transmission | Through 5VX powerband belts |

| Loading | Hydraulic self loading |

| Log Rotating: | Hydraulic log rotating |

| Log Dogging: | 4 hydraulic dogs |

| Slab Removal: | Hydraulic arms remove left over slabs |

| Timber Removal: | Sawm timber removed automatically by powerhead |

| Saw Dust: | Saw dust removed by conveyor |

| Rise and Fall: | Worm drive |

| Carriage Travel: | Hydraulic winch |

| Cutting: | Twins horizontal and vertical blades |

| Blades: | 30" vertical, 16" horizontal |

| Sharpening: | Jockey grinder for on site use |

| Timber Sizing: | 30" computer setworks |

| Maximum Cut: | 300mm x 150mm |

| Log Size: | 100mm to 1 meter |

| Sawn Volume: | Up to 20 cubic meters per day |

| Tools: | Necessary tools supplied |

| Training: | Training supplied |

Sawmills Co

Peterson Portable Sawmills

Petersons are the original designer of the world's first commercial "swingblade" portable sawmill. While other variations come and go, Peterson's continue to be leaders in innovation and design. Petersons are unique in that they listen to, and act upon, sawmiller’s responses from the field. Consequently, year after year, Peterson's continue to put out new and improved ways of converting logs to lumber.

All Terrain Sawmill –ATS

The All Terrain Sawmill has been designed as the ideal entry-level mill to portable sawmilling. It features all the benefits of its predecessor the Log Locust, plus new features to match our client’s demand for a mill that can handle the tough conditions of jungle, bush or forest. The ATS uses a raised track system, allowing it to be assembled on nearly any terrain type. It makes milling high volumes of wood easy, but without the large price tag attached to most commercial mills.

The focus behind the ATS design is ease of use for the operator. Made of alloy and stainless steel, the ATS is lightweight, highly portable, robust and rust resistant. Even on rough terrain it can be set up in 5-10 minutes and the operator can easily cut 2-4 cube (900-1800 bft) per day. Both track sizings are at the operator’s end to minimize walking, and the mill is easily upgradable to a 20/24hp motor or 8” blade if more power or a larger cut is required than the standard 13hp 6” mill allows.

Specifications

Blade: |

6" 8" 10" |

Motor: |

Choose from a Honda 13hp, 20hp, 24hpor Kohler 25hp, 27hp |

Maximum Cut: |

6¼" x 6¼"(160 x 160mm) 8¼" x 8¼"(210 x 210mm) 10¼" x 10¼" (260 x 260mm) |

Double Cut: |

5½" x 12½"(140 x 320mm) 8¼" x 16 ½"(210 x 420mm) 10¼" x 20½"(260 x 520mm) |

Max. Log Diameter: |

4' (1.2m) |

Max. log length on std tracks: |

20' (6m) |

Average Production: |

800 - 2500bft+ per day2 - 6+ cubic meters per day |

Accessories: |

Tapered Boards

Clip on Slabber

Dedicated Slabber

Drop in Slabber Brackets

Track Extensions

Tachometer

Large frame as standard |

INCLUDED WITH EVERY ATS MILL:

- Two standard circular blades◊ 20' + 6.5' (6m + 2m) two-piece tracks

- Sharpener kit and instructions◊ Safety Kit incl. muffs, visor, gloves

- Basic tools and spares in a watertight container

- Quality power unit with manufacturers warranty

- Jockey wheels for hand transfers

- Full documentation and training aids

PLUS

- Two-year return to base frame warranty, extendable to five years.

- CE Safety Certification (dependant on country)

- Unlimited phone support worldwide

Winch Production Frame -WPM.

Fast Product, Accurate Timber. These models are designed for fast production of high quality, extremely accurate timber. If you’ve got a pile of logs all ready to be milled up at one site, then this mill is ideal for you.

Mill Unlimited Length Beams. You can add extensions to any length without compromising accuracy or speed. In fact several of our millers have nearly doubled their production just by adding an extra set of tracks. One of our Canadian millers routinely saws 65’ logs.

Easy Log Loading. The fixed track method means you have easy access to the log and can cut timber from all sides. Logs can be moved into place either over a ramped low track or rolled under the high track.

Specifications:

| Motor: | Choose a Honda 13hp, 20hp, 24hpor Kohler 25 hp, 27hp |

| Blade: | 6" 8" 10" |

| Maximum Cut | 6¼" x 6¼"(160 x 160mm) 8¼" x 8¼"(210 x 210mm) 10¼" x 10¼" (260 x 260mm) |

| Double Cut | 5½" x 12½"(140 x 320mm) 8¼" x 16½"(210 x 420mm) 10¼" x 20½"(260 x 520mm) |

| Log Size: | Max. Log Diameter 4' (1.2m) 4' (1.2m) 5' (1.5m)

Max. log length 20' (6m) |

| Production: | 1200 - 3500bft+ per day3 - 8+ cubic meters per day |

| Accessories: | Track extensions

Hi/Lo Track Extensions

Tapered Boards

Drop in Slabber Brackets

Dedicated Slabber

Clip on Slabber

Max. log dia. now 7½' (2.3m) |

Automatic Swingblade Mill -ASM.

New and improved. The new remodelled ASM mill is set to revolutionise the portable sawmilling market, as it delivers increased and consistent production with much reduced effort. This mill can make horizontal and vertical cuts, change the size or depth of the cut, and remove the previous board cut all at the touch of a button. The operator can control the mill without moving an inch!

The control panel. Using simple setworks that don’t take a mathematician to operate, two buttons change the width of cut, and two buttons change the depth. The drive speed is controlled with a lever, which you move forward to go, and pull to bring back. It’s that easy, to get incredibly accurate boards with high production.

After an initial release in 2003 the ASM has been remodelled to make it simpler, lighter, stronger and more affordable. The difference. Weight is the biggest improvement with the new mill over 100kg lighter than the previous design. The design has been simplified substantially, and the engineering improved to reduce the weight to be only 70kg heavier than the manual machines. It now fits easier into the back of your ute/pick up.

An efficient design also reduces set up time. The number of parts has been minimized, allowing for a much simpler, and therefore faster set up time.

Specifications:

| Motor: | Choose 24hp Honda, 27hp Kohleror 20hp electric motor |

| Blade: | 8" 10" |

| Maximum Cut | 8¼" x 8¼"(210 x 210mm) 10¼" x 10¼" (260 x 260mm) |

| Double Cut | 8¼" x 16½"(210 x 420mm) 10¼" x 20½"(260 x 520mm) |

| Log Size: | Max. Log Diameter 6' (1.8m) 5' (1.5m)

Max. log length 20' (6m) |

| Production: | 2500 - 4200bft+ per day6 - 10+ cubic meters per day |

| Accessories: | Track extensions

Tapered Boards

Dedicated Slabber

Clip on Slabber

Electric Winch

Max. log dia. now 6½' (2m) |

Dedicated Wide Slabber -DWS.

High Value Timber. Wide slabs can be extremely valuable, up to five times the value of an equivalent amount of sawn dimensional timber. Attractive solid and/or live edge slabs can be used for kitchen counters, bar tops, tables and many other types of furniture.

Cutting up to 40 slabs per hour our dedicated slabber is a purpose built slabbing unit complete with it’s own motor, gearbox, bar and chain, fitted within our large 1.8m production frame. Designed with a faster chain speed ratio than other slabbers, it is more suited the manufacturers chain speed specifications, so that you can cut between 8-40 slabs per hour and retain accurate and quality finish.

Specifications:

| Motor: | Honda 13hp, 20hp, 24hp or Kohler 25hp, 27hp |

| Chain: | 404 ripping or double/multi skip tooth |

| Log Size: | Max. Log Diameter 5' (1.5m)

Max. log length 20' (6m) |

| Production: | 6 - 30 slabs per hour, depending on specs |

| Accessories: | Track extensions |

Peterson Sawmills

SELECT Sawmill Co. has been in business for 10 years and manufactures sawmill equipment with double-cut capability combined with an hydraulic system, central automated computer with memory setwork

SELECT Model 3620

Portable Sawmill is built tough and capable of a hard day's work. It will cut twice as fast as any other thin kerf mill. Built on a smaller scale the SELECT Model 3620 is assembled with the same superior quality as our SELECT Model 4221, and that is why this model stands out above the competition. This portable sawmill is for the sawyer who prefers to be on the move. Drive to the spot, set in place, level the sawmill, and there you are ready to start to saw in just a few minutes.

Specifications

Motor |

40 hp electric and 15 hp for dual hydraulic pump or 68 hp High powered John Deere Diesel Engine |

Blade |

4 inch double-cut swage tooth |

Band wheels |

32 inch |

Hydraulics |

log turner two back poststwo dogs two tapersblade tensioning blade guidehead liftcarriage feed |

Computerized Setworks |

8 thicknesses, preset board and 2 hold and recall memories for cutting hardwood |

Frame |

2" x 8" frame and crossers supported by 8 fully adjustable legs |

Cutting speed |

up to 2 feet per second |

Blade lubrication |

automatic electric blade lubrication |

Log size |

can cut logs up to 36 inches in diameter by 20 feet long |

SELECT Model 4221

Designed as a user friendly, high output commercial sawmill. Our mill's capability for high volume production is... what defines the SELECT Model 4221 as the ultimate band sawmill. High volume production is achieved with this mill's double-cut blade (cuts in both directions), high efficiency hydraulic system and computerized setworks with time saving features.

One of the features which is highly favored by our clients on both our Models 4221 and 3620, is the full hydraulic system enabling the operator to remain seated at the control station.

Built and designed for commercial use, the SELECT Model 4221 is renown for its exceptional quality, workmanship and performance. Powered by a 115 hp John Deere Turbo diesel engine or a 75 hp electric motor, this mill will cut effortlessly into any type of hard wood.

A close-up of the rollers on tapers and dogs

Motor |

115 hp John Deere turbo diesel engine or 75 hp electric |

Blade |

6 inch double-cut blade (cuts in both directions) |

Band wheels |

36 inch band wheels with double-tapered bearings |

Hydraulics |

log turner, two back posts, two dogs, two tapers, blade tensioning, blade guide, head lift, carriage feed |

Computerized Setworks |

Has 12 preset thicknesses and an additional two memories for hold and recall specially designed for cutting hardwood |

Frame |

Heavy duty frame made of 2 inches x 8 inches x 1/4 inch thick |

Cutting speed |

up to 3 feet per second |

Blade lubrication |

automatic electric blade lubrication |

Log size |

cuts logs up to 42 inches in diameter x 22 feet long |

Contact:

SELECT Sawmill CO.

5889 County Road 17

Plantagenet, ON

CANADA - K0B 1L0

TEL: 613-673-1267

FAX: 613-673-2854

http://www.selectsawmill.com/

The Timber Harvester is designed and built by people who are in the lumber business. We are third generation sawyers with more than 100 combined years of timber harvesting experience. We know and understand a sawyer's needs

Timber Harvester Bandmill Model 36HT25

The 30HT25 and 36HT25 models come with all hydraulics as standard equipment and are nearly identical, sharing the features listed below. The only differences are: the 30HT25 cuts logs up to 30" in dia. and has a 3000 lb. log lift; the 36HT25 cuts logs up to 36" in dia. and has a 5000 lb. log lift.

- Remote Control Semi-Automatic Saw Head actually saws lumber for you while you pull boards!

- Log Lift replaces manually loading the log onto the saw table and eliminates the need for extra equipment on the job.

- Log Turner positions the log or cant with a touch of the lever.

- Tapers lift either end of the log to get even starting cuts, decreasing slab waste.

- Blade Guide opens and closes the saw throat with the flip of a switch.

- Clamps & Posts complete the system of rapid, hands free, high production processing of logs into lumber!

- Both models also feature standard Board Dragbacks for automatic board removal, and huge 25" dia. Band Wheels for longer blade life and increased cutting speed.

- Accommodates a 20' log.

- 24 HP gas engine standard power source (diesel & electric options available)

30TL19 Model

At Timber Harvester, we recognize that not all sawyers have the same needs, or the same budgets. We've designed a full-function hydraulic mill, incorporating the most critical labor-saving features of our HT models, in an affordable package. With most logs the sawyer using a 30TL19 can grade saw as easily as with our most expensive mill. This mill shares Timber Harvester's fast log lift, clamp design, posts, and reversible chain turner with the HT models. The 30TL19 also features our dragback system, remote flow control, and remote control of sawhead. The mill is equipped with 19" band wheels, a dependable 24 HP gasoline engine, and full towing package. The hydraulic In-line Debarker is an available option with this model.

The 30TL19 features:

- Remote Control Semi-Automatic Saw Head

- Board Dragbacks

- Hydraulically controlled Log Lifting, Turning, Clamping, Raising, and Lowering Posts.

30H Model

The 30H is the mill for the sawyer who needs the power and ease of a hydraulic sawhead, but does not need the full range of hydraulic features offered on the HT and TL models. With the 30H, the log is loaded either from a live deck or with a tractor, and is positioned and clamped with positive manual clamps and posts. Once the log is in position, the actual sawing functions are hydraulically powered and controlled from the sawyers station through the remote control box. This is an excellent mill for the occasional sawyer, farmer, or woodlot owner who needs a solid, dependable mill, but is not looking for maximum for-profit production.

The 30H Features:

- Remote Control Semi-Automatic Saw Head

- With Hydraulically Controlled Saw Head Advance and Return

- Blade Height Adjustment.

Timberharvester

Wood - Mizer

Wood-Mizer is the undisputed world leader in sawmill sales, with over 30,000 mills in use in 110 countries. Wood-Mizer has dozens of branches worldwide, to serve customers on every corner of the map. In addition to high-quality products, we owe much of our success to our corporate culture. We view each employee, and each customer, as part of a very large family. Our customers are proud of what they have accomplished with their sawmills, and their pride shows with the thousands of pictures we receive each year. We of course, would like to see that family grow! To ensure that we are best serving the evolving needs of our current and future customers, we're developing and marketing more secondary processing equipment. Even if your mill is used only for personal projects, our edgers, moulders, and kilns can improve the appearance and value of your lumber. When we say "From Forest to Final Form ® ", we mean it!

LT10

A compact hobbyist mill operated with an easy hand push feed system. It features a 7.8 HP recoil gas engine with a pressure lube system and will cut up to 100 board feet per hour.* The base mill has the capacity to handle 24" diameter logs by 11 ' long. A space saving feature of the LT10 is that it breaks down and can be stored in your garage or outbuilding. The Wood-Mizer LT10 is designed as an entry level mill for the weekend sawyers who love the idea of cutting their own lumber but want to minimize their investment. As with all our mills, the LT10 is backed with the same legendary service, quality and safety features shared by the rest of the family of Wood-Mizer mills.

This is a hobbyist mill built to professional quality standards. The LT10 operates with an easy, hand-push feed system. It features a 7 HP recoil gas engine and will cut up to 100* board feet per hour. The base mill can handle 24" diameter logs up to 11' long. To save space, the LT10 stores easily inside your garage in three sections - bed, mast and head. For long logs, optional bed extensions will increase your cutting length by 7' and there is no practical limit to how many you can add. The LT10 is shipped directly to you on one pallet. Very little assembly is required, and the free DVD will get you ready to set up, saw and store. As with all our mills, the LT10 is backed with the same legendary service, quality and safety features shared by the rest of the family of Wood-Mizer portable sawmills.

LT10 - Specifications

| Log Capacity* | 24" dia. x 11' |

| Log Handling | Manual (Cant Hook) |

| Head Drive | Manual Hand Push |

| Operator Location | Walk |

| Power Options Selections | 7 HP recoil gas engine |

Note: All specifications are subject to change without notice.

* Due to many variable sizes, actual production figures may vary. Call for details

**Maximum log capacity 4,400 lbs.

LT10 FEATURES AND BENEFITS

- Water Lube System: Keeps the blade in optimum cutting condition.

- Blade Tension Activator: One throw of the lever gives proper tension automatically (see below).

- Four Movement Roller with Ball-Bearing: Ensures trouble-free head travel back and forth on the bed rails.

- Four Rail Cleaner and Roller Wipes: Helps to keep bed rails clean and free of debris.

- Large throat capacity: Allows cuts on cants up to 19.5" wide.

- Log Clamping System: Allows you to cut within 1" of the bed.

- Four Side Supports: Adjustable and removable to ensure accuracy and allow cuts within 1" of the bed rails.

LT 15

If you are a hobbyist, Wood-Mizer makes it easy for you to cut dimensional lumber like a pro.

The LT15 is a mighty little workhorse that works BIG. Quickly adjust the hand crank to change board thickness. Cut up to 125* board feet an hour, and cut straight and true, whether you are standing on hilly or level ground. Attach as many optional 6'8" bed extensions as you like for nearly unlimited log length. If you want to move your LT15, load'er up and go. It is super compact, so you easily load it in the back of a standard-sized pickup truck or tow the mill with the optional trailer package.

Dimensions (without trailer package)

Length 13'8" (4.2m)

Width 6'3" (1.9m)

Height 6'3" (1.9m)

Weight 944 lbs (428kg)

LT15 - Specifications

| Log Capacity* | 28" (71cm) dia., length 11' (3m) or no limit |

| Log Handling | Manual (Cant Hook) |

| Head Drive | Manual Hand Push |

| Operator Location | Walk |

| Power Options Selections | Standard 13HP (9.7kW) Gasoline

Optional 15HP (11.2kW) Gasoline

Optional 10HP (11.27.5kW) Diesel

Optional 10HP (7.5kW) Single or 3 Phase Electric |

LT15 FEATURES AND BENEFITS

- Carriage position: Quickly adjusted by a hand crank. The same crank moves the head up and down to change board thickness.

- Large throat capacity: Allows cuts on cants up to 23" wide.

- Best-in-class operator safety: Extensive guarding and combination clutch/blade-brake.

- Bed Sections: Have four integral levelers for quick setup.

- Clamping system: Allows you to cut within 1" of the bed.

- Semi-cantilevered head: With outboard roller and support, reduces both cost and weight.

- Manual blade-guide arm: Easily adjustable from the operator’s position for maximum blade stability.

- Superior paint quality: Wood-Mizer uses only the best paint for longer wear. We even paint the inside of the head, showing our attention to detail.

- Rope feed system: Wood-Mizer uses a rope feed system instead of cables to prevent rusting and to make it safer and easier to replace (a trip to the hardware store is all it takes).

- Zinc plating: Used in various wear areas to reduce rusting and increase longevity.

LT28

Woodworking enthusiasts who operate more often than just the occasional weekend will benefit from the features provided by the LT28. The manual crank and walk-along cutting operation are designed to make the LT28 just as easy to operate as its younger sibling, the LT15.

The LT28 also provides options unmatched by other manual mills. The optional power feed allows you to move the cutting head down the log and back easier and at a faster pace. You can also add the optional log deck package to handle loading, leveling, and turning logs just as well as a hydraulic mill, without the added investment. The package includes a manual winch, a log turner and toeboards.

Transporting the mill is easy since the trailer package is a standard feature for the LT28, and as with each of our mills, setup is quick and effortless with the LT28 with Wood-Mizer's patented monorail system. Instead of hauling logs, start your project on the spot

LT28 - Specifications

Dimensions (with trailer package)

Length 26'2" (8m)

Width 6'6" (2m)

Height 8'5" (2.6m)

Weight 2420 lb (1098kg) with heaviest power options

Maximum Cutting Capacities

Log Capacity * 32" (81cm) dia., length 21' (6.4m)

Production Rates ** up to 200 bd.ft./hr.

Maximum log capacity for a basic mill is 4,400 lbs. (1,996kg).

** Due to many variables, actual production figures may vary. Call for details.

LT28 FEATURES AND BENEFITS

- Water Lube System: Keeps the blade in optimum cutting condition.

- Main Bed Torque Tube: The same frame used on all Wood-Mizer professional sawmills.

- Clamping System: Enables you to cut within 1" of the bed.

- Manual Blade-Guide Arm: Easily adjustable from the operator's position.

- Monorail Sawhead : Assures fast setup, easy leveling, and accurate cuts.

- Loading Ramps: Provides easy loading of logs when used with the optional manual winch.

- Four Main Bed Supprts and Two Swing Arm Supports: Adjustable to assure accuracy.

- Durable Main Rails: Induction-hardened, precision steel rods welded to the main frames 4" x 8" torque tube to ensure accuracy for the life of the mill.

- Stainless Steel Bed Sleeves: Protect the saw bed from wear, prevent staining of hardwoods and reduce effort in turning logs.

LT40

A proven veteran. It was the first portable sawmill on the market in the early 80's and remains the sawyer's favorite. The LT40 features simple manual operation, an electric feed system to boost productivity, and one central location for all the mill controls. The famous Wood-Mizer monorail head assures fast setup, easy leveling and accurate cuts. Fully supported swing arms adjust for various length logs and allow accurate cuttings on longer logs. Three hundred board feet an hour never looked so good! For options to boost performance even further, look at the blade-saving debarker and the Simple Setworks system, which calculates the thickness of cuts and kerf loss. It's good to have a steady hand like the Wood-Mizer LT40 working for you. Over the years, we've improved the design, but the basic idea still works - productivity + portability = profits! That simple idea is unchanged. Even better, it is unchallenged.

LT40 - Specifications

Dimensions (with trailer package)

Length 26'2" (8mm)

Width 6'6" (2m)

Height 10' 6" (3.2m)

Weight 3281 lb (1488kg) with heaviest power options

Maxiumum Cutting Capacities

Log Capacity * 36" (91cm) dia., length 21' (6.4m)

Production Rates ** up to 300 bd.ft./hr.

* Maximum log capacity 4,400 lbs.

** Due to many variables, actual production figures may vary. Call for details.

*** Optional Bed Extensions increase cutting length by 6', 12', or 24' up to 45'.

† Command Control & remote operator station accommodate one 6' bed extension only.

Note: All specifications are subject to change without notice.

LT40 STANDARD FEATURES AND BENEFITS

- Fully supported swing arms:Adjust for different log lengths and allow longer length logs to be accurately cut.

- Centralized cutting controls:Located on central console. Includes head movement and blade guide arm in-out. Optional: debarker and LaserSight.

- Monorail/Sawhead: Assures fast setup, easy leveling, and accurate cuts.

- Adjustable outriggers:For simple rough leveling. Optional fine-adjust outriggers available.

- Removable gas tank and blade water bottle:Can be lowered for easy access to mill.

- Large throat capacity:Allows for cuts up to 28" wide.

- Solid-state power feed unit:Drives the carriage at any speed up to 135 feet per minute and returns the carriage at 145 feet per minute.

- Durable main rails:Induction-hardened, precision steel rods welded to the main frame’s 4" x 8" torque tube help ensure accuracy for the life of the mill.

- Stainless Steel Bed Sleeves :Protect the saw bed from wear and also prevent staining of hardwoods.

- Clamping system:Enables you to cut within 1" of the bed.

- Trailer Package:Trailer package includes: loading ramps, adjustable outriggers, axle, rims, tires, fenders, wiring harness, running/turning/stop lights, trailer hitch with ball coupler assembly, and safety chains.

LT40 Hydraulic

Step up to the Wood-Mizer LT40 Hydraulic sawmill and leave behind the heavy lifting. The LT40 Hydraulic cuts up to 400 board feet per hour while removing much of the physical labor associated with sawing.

With this mill, you handle the log with a touch! Six hydraulic levers load, level, clamp and turn the log. Once the log is ready, just set the board thickness and blade speed from the centralized cutting control and walk along with each cut. An optional ride-along seat is available as an upgrade.

Other upgrades include an optional Command Control station that brings all controls to the head of the mill, including the hydraulic log handling levers. The station also brings the optional Accuset Setworks, AutoClutch, LaserSite, and Debarker to your fingertips.

LT40 HYDRAULIC - SPECIFICATIONS

Dimensions (with trailer package)

Length 26'2" (8m)

Width 6'6" (2m)

Height (maximum head position) 10'6" (3.2m)

Weight (with heaviest power options) 3900 lb (1769kg)

Maximum Cutting Capacities

Log Capacity * 36" (91cm) dia., length 21' (6.4m) and up to 45'(13m) w/bx

Production Rates ** up to 400 bd.ft./hr.

* Maximum log capacity for a basic mill is 4,400 lbs (1,996kg).

** Due to many variables, actual production figures may vary. Call for details.

*** Optional Bed Extensions increase cutting length by 6', 12', or 24' up to 45'.

†Command Control accommodates one 6' bed extension only.

Note: All specifications are subject to change without notification.

STANDARD FEATURES AND BENEFITS

- 12-volt hydraulic pump, reservoir, and control box:Mounted on the front of the mill. All hoses are mounted inside the main bed tube. (No second engine required.)

- Centralized cutting controls:Located on central console. Includes head movement and blade guide arm in-out. Optional: Accuset, AutoClutch, LubeMizer, debarker, and LaserSight.

- Log side supports:Raised and lowered remotely through the control box.

- Cantilevered head:Assures fast setup, easy leveling, and accurate cuts.

- Adjustable outriggers:For simple rough leveling. Optional fine-adjust outriggers available.

- Removable gas tank and blade water bottle:Can be lowered for easy access to mill.

- Trailer Package:Includes adjustable outriggers, axle, rims, tires, fenders, brakes, wiring harness, running/turning/stop lights, trailer hitch with ball coupler assembly, and safety chains.

- Large throat capacity:Allows for cuts up to 28" wide.

- Stainless Steel Bed Sleeves :Protect the saw bed from wear and also prevent staining of hardwoods.

- Roller/block blade guides:Ensure accuracy, blade stability and increased blade sharp life.

- Solid-state power feed unit:Drives the carriage at any speed up to 135 feet per minute and returns the carriage at 145 feet per minute.

- Fully supported swing arms:Adjust for different log lengths. Bed bracing improves bed rigidity and strength.

- Mill chassis:Design is much more durable than most twin-rail designs.

LT40H- OPTIONS

- Bed Extensions:Optional 6', 12', or 24'

- Accuset:You are no doubt the brains of the mill. But it's nice to have someone, or something else thinking right along with you. That's where Accuset Setworks comes in. All you have to do is enter your desired board thickness, and the head automatically lowers to the right height, including kerf-loss. You just can't get more accurate cuts. Even for entire stacks of wood, Accuset does all the complicated calculations. Accuset takes away all the guesswork.

- Wood-Mizer Debarker: Nature's debris can be a sawyer's downfall. When logs are moved, they often collect mud, rocks, bark, and whatever else just happens to be on the ground. Do your blades a favor by de-barking your logs as you cut them with a Wood-Mizer De-barker. Its powerful 3/4 HP motor removes the blade-dulling crud just in front of the blade. You get longer blade life between sharpenings, and you don't have to power-wash a single log. Give your blades, and your pocketbook a break. De-bark your logs with a Wood-Mizer Debarker.· Log Turner: This simple accessory, when used in conjunction with the manual winch, enables a single operator to rotate larger diameter logs.· Toeboards: Mounted on the sawmill bed's front and rear cross members, the toeboards enable you to lift either end of a tapered log by hand crank.

- LaserSight Option:Some sawyers just have an eye for knowing where the blade's going to hit the wood. But you can let our LaserSight be your second pair of eyes. LaserSight, a laser beam, indicates exactly where the blade will cut through the log. This beam of light helps you minimize your slabs and that allows you to save time and increase yield. LaserSight may be retrofitted to any Wood-Mizer mill equipped with a 12-volt battery.

- Operator Seat: Even the hardest-working sawyers like to rest their feet once in a while. That's why we designed this soft contoured seat to be easily installed, without tools. When you want to take a break, you can quickly add the OS and be back sawing within minutes.

- Sawmill Covers:Don't risk rust! We have carriage covers to fit all of our sawmill models. These tough covers are made from high-quality, fiber-reinforced material and come with metal eyelets and rubber shock-cords for protection against strong winds. Our one-piece cover (CC) protects the cutting head, engine, control console, and power feed motors. The two-piece cover (CEC) protects just the engine and control console. Don't let your mill get caught in the storm!

LT40 Super Hydraulic

Move up to the big leagues with the LT40 Super Hydraulic sawmill. This powerful mill offers optimum hydraulic features that boost productivity and profitability for the full-time sawyer. The LT40 Super Hydraulic cuts up to 550 board feet per hour and comes standard with hydraulic loading arms, a pair of hydraulic roller toeboards, a hydraulic log clamp, and a hydraulic log turner. An automatic board return system speeds up off-bearing, increasing overall productivity. You'll love the LT40 Super Hydraulic Optional Command Control operator station. This convenient console gives the sawyer fast and easy access to all hydraulic controls and cutting functions such as board thickness and head movement speed. Accuset Setworks and AutoClutch are included in the Command Control system.

LT40 SUPER HYDRAULIC - SPECIFICATIONS

Dimensions (with trailer package)

Length 26'2" (8m)

Width 6'6" (2m)

Height (Maximum head position) 11' (3.3m)

Weight (With heaviest power options) 4210 lbs (1909kg)

Maximum Cutting Capacities

Log Capacity * 36" (91cm) dia., length 21' (6.4m) and up to 45' (13m) w/bx

Production Rates ** up to 550 bd.ft./hr.

* Maximum log capacity for a basic mill is 4,400 lbs (1,996kg).

** Due to many variables, actual production figures may vary. Call for details.

*** Optional Bed Extensions increase cutting length by 6', 12', or 24' up to 45'.

†Command Control accommodates one 6' bed extension only.

Note: All specifications are subject to change without notice.

STANDARD FEATURES AND BENEFITS

- Mill chassis:Cantilever design is much more durable than most twin-rail designs.

- Power movement:High-output electric motors move the head up/down and drive the carriage at any speed up to 170 feet per minute and return the carriage at 200 feet per minute.

- Centralized cutting controls:Located on central console. Includes head movement and blade guide arm in-out. Optional: Accuset, AutoClutch, LubeMizer, debarker, and LaserSight.

- Log side supports:Raised and lowered remotely through the control box.

- Cantilevered head:Assures fast setup, easy leveling, and accurate cuts.

- Adjustable outriggers:For simple rough leveling. Optional fine-adjust outriggers available.

- Removable gas tank and blade water bottle:Can be lowered for easy access to mill.

- Trailer Package:Includes adjustable outriggers, axle, rims, tires, fenders, brakes, wiring harness, running/turning/stop lights, trailer hitch with ball coupler assembly, and safety chains.

- Large throat capacity:Allows for cuts up to 28" wide.

- Stainless Steel Bed Sleeves :Protect the saw bed from wear and also prevent staining of hardwoods.

LT40 SUPER HYDRAULIC • OPTIONS

- Bed Extensions:Optional 6', 12', or 24'

- Accuset:You are no doubt the brains of the mill. But it's nice to have someone, or something else thinking right along with you. That's where Accuset Setworks comes in. All you have to do is enter your desired board thickness, and the head automatically lowers to the right height, including kerf-loss. You just can't get more accurate cuts. Even for entire stacks of wood, Accuset does all the complicated calculations. Accuset takes away all the guesswork.

- Wood-Mizer Debarker:Nature's debris can be a sawyer's downfall. When logs are moved, they often collect mud, rocks, bark, and whatever else just happens to be on the ground. Do your blades a favor by de-barking your logs as you cut them with a Wood-Mizer Debarker. Its powerful 3/4 HP motor removes the blade-dulling crud just in front of the blade. You get longer blade life between sharpenings, and you don't have to power-wash a single log. Give your blades, and your pocketbook a break. De-bark your logs with a Wood-Mizer De-barker.

- LaserSight Option:Some sawyers just have an eye for knowing where the blade's going to hit the wood. But you can let our LaserSight be your second pair of eyes. LaserSight, a laser beam, indicates exactly where the blade will cut through the log. This beam of light helps you minimize your slabs and that allows you to save time and increase yield. LaserSight may be retrofitted to any Wood-Mizer mill equipped with a 12-volt battery.

- Operator Seat:Even the hardest-working sawyers like to rest their feet once in a while. That's why we designed this soft contoured seat to be easily installed, without tools. When you want to take a break, you can quickly add the OS and be back sawing within minutes.

- Command Control Operator Station:Why leave the action? All the bells and whistles on your mill can be in the same place! Our Command Control option puts all the controls at the head of the mill, even the hydraulic log handling. We even threw in our Accuset Setworks! Command Control makes our mills the easiest in the world to operate. It's the perfect way to work for the experienced sawyer.

LT70 -

A serious sawmill for serious sawyers. Our most productive portable sawmill will help you build a profitable business. You can expect to cut up to 800 board feet per hour. Advanced hydraulics are standard features of the LT70 - hydraulic loading arms, a pair of hydraulic roller toeboards, a hydraulic log clamp, and a hydraulic chain turner which is 40 percent faster than standard steel claw turners. The chain turner also moves in both directions for added convenience. You will precisely set board thickness and blade speed with your centralized cutting control station beefed up with standard Accuset, AutoClutch and LubeMizer features. Air bag blade tensioning offers better blade performance while extending blade life.

Also available: a movable remote operator station is available; a new material handling system (log infeed deck, inclined conveyor, transfer table); and an industry-leading 62HP diesel engine. In tests, the 62HP engine increased the LT70's production rate by up to 35%, compared to the 42HP engine. The LT70 will help you make the most quality with your time, and will produce greater profits for your sawmill operation. Now, that's power

LT70 - SPECIFICATIONS

Dimensions (with trailer package)

Length 26'2" (8m)

Width 6'6" (2m)

Height (maximum head position) 11' (3.3m)

Weight (with heaviest power options) 4590 lb (2059kg)

Maximum Cutting Capacities

Log Capacity * 36" (91cm) dia., length 20'2" (6.1m)and up to 45' (13m) w/BX

Production Rates ** up to 800 bd.ft./hr.

* Maximum log capacity 4,400 lbs.

** Due to many variables, actual production figures may vary. Call for details.

*** Optional Bed Extensions increase cutting length by 6', 12', or 24' up to 45'.

†Command Control and Remote Operator Station accommodate one 6' bed extension only.

Note: All specifications are subject to change without notice.

STANDARD FEATURES AND BENEFITS

Roller block blade guides: Accurate cutting with increased blade stability.

- Dead shaft drive system:Massive maintenance-free sealed bearings.

- Hinged blade wheel covers:Facilitate quick blade changes and are easy to close and fasten.

- Idler pulley clutch system:Easy access to drive belt for routine maintenance.

- Single column mast:Even easier maintenance and alignment.

- Air bag blade tensioning:Improved blade tension consistency in all cutting conditions.

- Large cam follower bearings:3" diameter bearings used on the topside. Dual saddle bearing arrangement on the operator side yields increased bearing life. Very little maintenance required.

- Hydraulic vertical side supports:15" high. Massive 2" diameter hardened chrome shaft for superior durability.

- Direct drive power feed:No drive belts. Dual bearing support of gearbox output shaft.

- Accuset:Wood-Mizer’s powerful setworks comes standard on the LT70.

- Trailer Package:Includes adjustable outriggers, axle, rims, tires, fenders, brakes, wiring harness, running/turning/stop lights, trailer hitch with ball coupler assembly, and safety chains.

- AutoClutch:Electronically- controlled lever to engage blade. Controlled from operator panel. Comes standard with the LT70.

LT70 - Options

- Bed Extensions: Optional 6', 12', or 24'

- Wood-Mizer Debarker: Nature's debris can be a sawyer's downfall. When logs are moved, they often collect mud, rocks, bark, and whatever else just happens to be on the ground. Do your blades a favor by de-barking your logs as you cut them with a Wood-Mizer Debarker. Its powerful 3/4 HP motor removes the blade-dulling crud just in front of the blade. You get longer blade life between sharpenings, and you don't have to power-wash a single log. Give your blades, and your pocketbook a break. De-bark your logs with a Wood-Mizer Debarker.

- LaserSight Option: Some sawyers just have an eye for knowing where the blade's going to hit the wood. But you can let our LaserSight be your second pair of eyes. LaserSight, a laser beam, indicates exactly where the blade will cut through the log. This beam of light helps you minimize your slabs and that allows you to save time and increase yield. LaserSight may be retrofitted to any Wood-Mizer mill equipped with a 12-volt battery.

- Operator Seat: Even the hardest-working sawyers like to rest their feet once in a while. That's why we designed this soft contoured seat to be easily installed, without tools. When you want to take a break, you can quickly add the OS and be back sawing within minutes.

- Movable Remote Operator Station: Why leave the action? All the bells and whistles on your mill can be in the same place! Our CommandControl option puts all the controls at the head of the mill, even the hydraulic log handling. We even threw in our Accuset Setworks! CommandControl makes our mills the easiest in the world to operate. It's the perfect way to work for the experienced sawyer.

- Sawmill Covers: Don't risk rust! We have carriage covers to fit all of our sawmill models. These tough covers are made from high-quality, fiber-reinforced material and come with metal eyelets and rubber shock-cords for protection against strong winds. Our one-piece cover (CC) protects the cutting head, engine, control console, and power feed motors. The two-piece cover (CEC) protects just the engine and control console. Don't let your mill get caught in the storm!

Woodmizer |

|