| | Operation | New controls and adjustments | Iron removal | General | Troubleshooting

Hard water is very common in many areas of Alberta. Hard water causes scale to form in pipes, plumbing fixtures and kitchen appliances. Soap reacts with hard water to form a curd, and hard water can also cause skin flaking and irritation. More soap or detergent is needed when washing or laundering with hard water.

Hardness is primarily caused by the dissolved chemical compounds of calcium and magnesium. The amount of hardness is expressed in milligrams per litre (mg/L) or grain per gallon (gpg) as calcium carbonate.

Table 1.

| Type of water | Amount of hardness |

| mg/litre | gpg |

| Soft | 0 - 50 | 0 - 3 |

| Moderately soft | 50 - 100 | 3 - 6 |

| Moderately hard | 100 - 200 | 6 - 12 |

| Hard | 200 - 400 | 12 - 23 |

| Very hard | 400 - 600 | 23 - 35 |

| Extremely hard | over 600 | over 35 |

The level at which hardness becomes inconvenient depends on individual preference; however, water softening is recommended when hardness exceeds 100 mg/L (6 grains per gallon). Water with a hardness approaching or exceeding 1,000 mg/L is likely too hard to be worthwhile softening.

Table 2. Water softener size (grains) - based on 3-day cycle

Number of persons

in household | Litres of water used

per day | Hardness (mg/L) |

200 | 400 | 600 | 800 |

2 | 1,000 | 7,500 | 15,000 | 22,500 | 30,000 |

4 | 2,000 | 15,000 | 30,000 | 45,000 | 60,000 |

6 | 3,000 | 22,500 | 45,000 | 67,500 | 90,000 |

8 | 4,000 | 30,000 | 60,000 | 90,000 | 120,000 |

Operation

Water softeners operate on the principle of ion exchange. A synthetic resin (zeolite) bed is charged with sodium ions by regeneration with salt (sodium chloride). Hard water, containing calcium and magnesium ions, flows through the resin.

Ion exchange occurs when the calcium and magnesium ions attach themselves to the resin, displacing the sodium ions. The resultant water is softened, being free from calcium and magnesium, but the sodium content is increased. Usually, the sodium increase will be approximately 50 mg/L sodium per 100 mg/L of hardness.

The amount of hardness a softener can remove depends primarily on the amount of resin in the softener. One (1) cubic foot of a typical high capacity resin can remove 30,000 grains or about 500,000 milligrams of hardness. This means that if water is 500 mg/L hard, 1 cubic foot of resin would soften 1,000 L of water before requiring regeneration.

In Table 2, an estimate of the required softener size, in grains, is shown. One can see that the required size increases proportionally with an increase in hardness or water use. The shaded area identifies the more common sizing range of water softener sizes, but suppliers can select softener sizes and controls to deal with most situations. For instance, this table is based on a 3-day regeneration cycle. If a 6-day cycle is a better fit, the sizes shown would double.

The five-cycle fully automatic water softener It is recommended that five-cycle, fully automatic water softeners be used for domestic water softening. This type of water softener is automatically and regularly backwashed and regenerated, which is essential for efficient operation.

The five cycles are as follows:

- Service – the water is being softened.

- Backwash - the direction of flow is reversed and the silt, sediment and iron particles are flushed from the resin. The backwash cycle on a typical softener requires a flow rate of about 13 L/min (3 gallons per minute). Water consumption for the regeneration of most domestic softeners is 300 to 450 L (70-100 gallons).

- Brine – the brine solution is slowly passed through the resin, until the resin retains as much sodium as possible.

- Rinse – excess brine is rinsed from the resin.

- Fast rinse – the resin bed is compacted for maximum operating efficiency.

The water softener then returns to the service cycle.

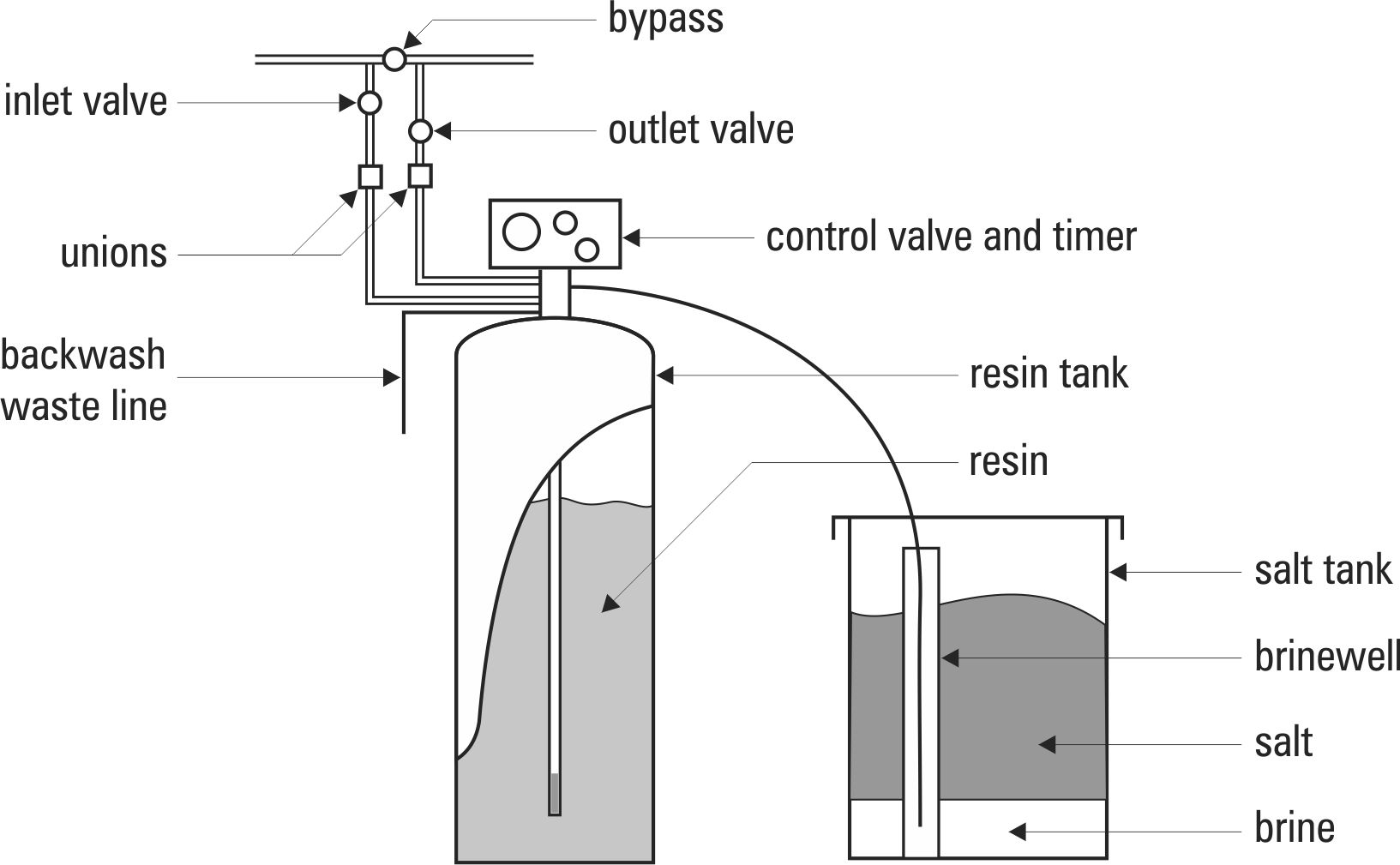

The fully automatic water softener consists of the following (see Figure 1):

- The resin tank – contains the zeolite resin and sometimes a sand layer to support the resin bed.

- The salt tank – contains the salt and saturated brine solution used in regeneration.

- The filter head – contains a timer that automatically operates the control valve that initiates the five cycles of the water softener. This clock controls the time of day that regeneration occurs and the number of days between regenerations.

Most water softeners can be set to regenerate every 1, 2, 3, or 6 days, depending upon the setting of the time clock.

Figure 1. Water softener, twin tank type

New Controls and Adjustments

Most softeners are adjusted to regenerate around 2:00 a.m. when no water is required in the house. Some models have a built-in hardness sensor that starts regeneration when it is required. Since iron often tends to foul these sensors, these models are not recommended if the water contains any iron or iron bacteria.

Approximately 6 kilograms of pelletized salt are required to completely regenerate each cubic foot of resin. The salt is dissolved in water in the salt tank. To conserve salt, softeners are often adjusted to draw about half the full dose of salt. A half dose of salt will regenerate a softener to about two-thirds of its maximum capacity. The salt setting is adjustable on almost all softeners.

The fully automatic water softener can be obtained in two styles: side-by-side (twin tank) models (Figure 1) and cabinet models. The cabinet type has the resin tank located inside the salt tank.

Iron Removal

Up to 3 mg/L of iron can readily be removed with a five-cycle fully automatic softener. If the water supply contains iron, a sodium hydrosulphite resin cleaner (“Ferrid”, “Iron-out,” “Lykopon,” “Sofnergard,” etc.) should be used regularly according to the manufacturer’s instructions. If the iron is not cleaned from the softener, its capacity will be drastically reduced.

General

Before purchasing a water softener, the water supply should be chemically analysed to determine the hardness, iron, sodium and sulphate content. See Agdex 716 (D04) Chemical Analysis of Farm Water Supplies. Water that is already high in sodium or sulphates should not be softened for drinking purposes, since softening increases the sodium concentration. Excessive levels of sodium in water my be detrimental to persons on sodium-restricted diets. People on sodium-restricted diets should consult with their physicians if the water supply contains more than 20 mg/L sodium. Softening water high in sulphates may increase the laxative effect and also cause an unpleasant taste.

If you do not want to drink softened water, bypass the softener for the cold water tap in the kitchen, or install a third tap for hard water. Softened water is usually harmful to plants because of its high sodium content.

More information

Additional information is available through health inspectors, agricultural water specialists or on the web.

The Rural Water Quality Information Tool on the Alberta Agriculture and Forestry website can help assess water test results and provide links to additional fact sheets and websites regarding water treatment.

Additional information is available through Agricultural Water Specialists or on the Alberta Agriculture and Forestry website.

Agricultural Water Specialists can be contacted through the Alberta Ag-Info Centre at 310-FARM (3276).

Prepared by:

Farm Water Supply Branch

Alberta Agriculture and Forestry

|

| Problem | Probable cause | Remedy |

| 1. Softener will not automatically generate | a. Timer, meter or sensor inoperative | a. Replace or repair defective part |

| b. Defective wiring between timer and sensor or timer and motor | b. Repair connections |

| c. Defective power cord | c. Replace cord |

| d. Softener is plugged into intermittent power source (i.e. socket or light switch) | d. Connect to constant |

| e. Cord unplugged | e. Plug in |

| f. Timer pins or screws not set | f. Set pins |

| 2. Conditioner regenerates at wrong time of day | a. Timer improperly set | a. Reset timer according to instructions |

| 3. Water runs to drain from softener during service cycle | a. Defective drain valve | a. Repair or replace drain valve |

| 4. Water runs to drain from brine-tank overflow | a. Float valve obstructed or makes faulty lower seal | a. Remove obstruction or replace seal |

| b. Cracked or defective brine riser pipe | b. Replace brine riser pipe |

| c. Defective timer of seal within valve | c. Repair or replace timer or seal |

| 5. Softener does not draw brine | a. Softener drain hose kinked or plugged | a. Remove obstruction or replace hose |

| b. Softener drain hose elevated too high causing back pressure | b. See manufacturer’s height specifications |

| c. Brine line and/or fittings plugged or obstructed | c. Remove obstruction; replace as necessary |

| d. Aspirator plugged or defective | d. Repair or replace |

| e. Restriction in brine riser or brine tube | e. Clean or replace |

| f. Low water pressure | f. Increase pressure |

| 6. Hard water bleed or bypass during service | a. Manual bypass valves open or defective | a. Close, repair or replace valve |

| b. Defective bypass seal or seal in main valve | b. Clean, repair or replace |

| c. Internal dip tube cracked or not properly secured | c. Repair or replace |

| d. Improper regeneration | d. Check brine draw system for sufficient volume |

| e. No salt or salt bridge in salt tank | e. Check salt |

| f. Softener too small | f. Install larger unit |

| g. Softener not regenerating often enough | g. Reset timer |

| h. Softener fouled by iron | h. Use resin cleaner |

| 7. Salt in lines after regeneration | a. Low water pressure | a. Adjust pressure to minimum recommended by manufacturer |

| b. Restricted or plugged backwash or rinse valving | b. Clean or replace |

| c. Top distributor plugged | c. Clean or replace |

| d. Softener drain valve or hose plugged or restricted | d. Clean or replace |

| 8. Using too much salt | a. Improperly adjusted brine valve or tube | a. Adjust to specification |

| b. Defective float seal | b. Clean or replace |

| c. Water leaks in brine | c. See 5 A, B, C |

| d. Regenerating too frequently | d. Reset timer |

| 9. Low water pressure | a. Municipal pressure low, low pump pressure or defective well pump | a. Investigate and correct as necessary |

| b. Restriction in water lines or other water equipment | b. Investigate and correct |

| c. Distributors and/or riser pipe plugged | c. Clean or replace |

| d. Plugged resin | d. Clean resin bed (See 10) |

| 10. Iron bleed | a. Iron-fouled resin bed | a. Clean iron from softener |

| b. Too much iron in water for softener to remove | b. Install iron removal equipment |

| c. Iron bacteria | c. Shock chlorinate well |

| 11. No soft water after regeneration | a. Unit didn’t regenerate | a. See 1 and 5 |

| b. No salt or salt bridged in tank | b. Check salt tank |

Source: Agdex 716(D32). Revised August 2011. |

|