| | Operation of distillers | Cost of operation | Maintenance | Certification of distillers

Water distillers can remove most minerals, metals, organic chemicals and micro-organisms from water. A clean, well-maintained distiller will remove over 95 per cent of the minerals, including sodium, sulfate, nitrate and arsenic. Biological contaminants such as bacteria, viruses and cysts are destroyed during distillation. Water distillers can be simple, versatile drinking water treatment devices.

Distillation will also remove beneficial elements such as calcium and magnesium; however, water is not a significant source of these minerals when compared to food sources in a well balanced diet.

Distillers are generally only used for producing small amounts of water for drinking and cooking, which is due to the cost of operation and slow rate of treated water production. When larger amounts of treated water are required, then a reverse osmosis system (RO) is often more suitable.

The choice between using a distiller and using reverse osmosis will depend on the amount of water needed, the quality of water needed and the pre-treatment required to protect the RO or distiller from damage. See the Alberta Agriculture and Forestry factsheet Reverse Osmosis Water Treatment, Agdex 716(D36).

The major operational limitation of distillers is scaling due to hard water. Lime scale tends to build up in the boiling chamber. Dealing with this scaling requires constant maintenance or pre-treatment using a water softener. Distillers may also fail to remove some volatile organic compounds from the water. These can be carried over into the treated water reservoir unless the distiller has a volatile gas vent or activated carbon filter.

Operation of Distillers

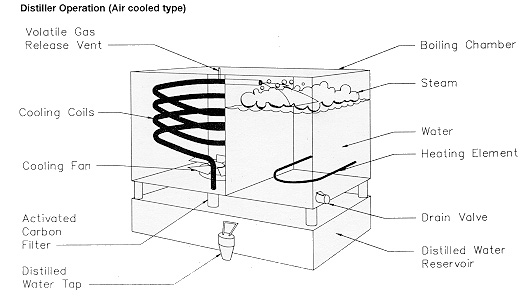

Distillers work on the principle of evaporation and condensation. An electric heating element (1,000 to 1,500 watts) boils water in a stainless steel tank. The resulting steam leaves the tank and enters a stainless steel cooling coil. In the cooling coil, the steam condenses to form distilled water. Some distillers use air to cool the steam. Others use incoming water for cooling.

When most of the water is boiled out of the distiller, a float switch turns off the power to the heating element. The concentrated mineral solution left in the boiling tank is drained off, and the boiling chamber is refilled manually or automatically.

Some distillers are built as portable countertop units. These are usually refilled manually and plugged into normal 120 volt power outlets. Countertop units normally batch distill 3 to 4 litres of water at a time.

Other distillers are permanently installed, usually in the house basement. They are plumbed into a water supply line, distilled water is collected in a storage container, and then a small pump is used to pump water to treated water taps, humidifiers, or fridges and icemakers. These units are normally continuous flow type distillers.

Cost of Operation

A small 4 to 5 litre (L) batch distiller with a 1,000 watt (1 Kilowatt) element will produce about 1 L of distilled water per hour. Therefore, the electrical cost per L of distilled water is equal to the electricity cost per kilowatt hour. For example, if your electricity cost is 8 cents/Kwh, the cost of distilling water will be 8 cents/L.

Costs will increase if scale accumulates on the electric heating element; therefore, it is important that the unit be properly maintained. Although more expensive, self-feeding or continuous flow distillers are usually more efficient and will likely decrease the cost of electricity.

The distiller must be kept out of the reach of children. Distillers will give off heat, and this factor should be considered when finding a place for them. They should also be put on their own electrical circuit to prevent electrical overload.

Figure 1. Distiller operation (air-cooled type)

Maintenance

Distiller models that are designed for easy cleaning and have an automatic flush system are recommended.

Hard water will cause scale buildup in the boiling chamber, so removing the scale from the heating element and reservoir is often required. Cleaning can be done with a commercial kettle descaling product or with a vinegar solution.

Fill the boiling tank with a solution of 1 part white vinegar to 1 part water and heat for 1 hour. Then, turn off the power, and let the solution sit in the boiling tank. The amount of time depends on the amount of scale built up on the element. If there is a lot of scale, the vinegar solution may have to sit in the chamber for a longer time. Leaving the solution in the tank overnight means the loose scale can then be scraped, brushed and flushed away.

If your water is very hard, you may be best off to soften the water before distilling it. This step will reduce the maintenance requirement. Distillers with automatic flush systems can extend the time between cleanings. Manual flushing can be done once a week if there is no automatic flush.

Ongoing preventive maintenance can be provided by adding 250 millilitres of vinegar to every fifth or sixth batch. The sludge is cleaned out after this batch is complete. The distilled water can be used since there will be no significant difference in the quality of this batch.

The distilled water holding tank should also be disinfected and rinsed with clean water periodically. Distilled water is often stored in glass containers in the fridge. These containers should also be disinfected with chlorine and rinsed periodically.

If the boiler is not working properly (bubbles are too strong and force water into the vapor collection tubing), contaminants can be carried over into the “distilled” water. The float valve in the boiling chamber may also stick and allow impure water into the holding tank.

If the distiller has an activated carbon filter, it should be changed every 3 months or every 150 to 200 gallons of distilled water. The carbon filter removes volatile organic chemicals, tastes, odours and chlorine that distillation does not remove. Bacteria can also populate activated carbon filters. Cooling fan and coils should be dusted as needed. Dust can burn and give off odors.

Certification of Distillers

Health Canada recommends that all products that come into contact with drinking water be certified to the appropriate health-based performance standard developed by NSF International. In the case of distillation units, it is recommended that they be certified as meeting standard NSF/ANSI 62.

Components employed in conjunction with the distillation system (such as filters) should also be certified to meet other applicable NSF/ANSI Standards. These standards have been designed to safeguard drinking water by helping to ensure material safety and performance of distillation units that come into contact with drinking water.

In Canada, CSA International, NSF International, QAI, IAPMO and Underwriters Laboratories have been accredited by the Standards Council of Canada to certify drinking water materials as meeting the above-mentioned standards. These standards are widely accepted in North America as they ensure the removal of specific contaminants as well as the performance and mechanical integrity of the materials that come into contact with drinking water. Ask your dealer or retailer for a list of the substances that the unit is certified to remove.

More information

Additional information is available through health inspectors, agricultural water specialists or on the web.

The Rural Water Quality Information Tool on the Alberta Agriculture and Forestry website can help assess water test results and provide links to additional factsheets and websites regarding water treatment.

Additional information is available through Agricultural Water Specialists or on the Alberta Agriculture and Forestry website.

Agricultural Water Specialists can be contacted through the Alberta Ag-Info Centre at 310-FARM (3276).

Prepared by

Farm Water Supply Section

Alberta Agriculture and Forestry

Source: Agdex 716 (D62). Revised May 2011. |

|