| | Operation | Installation | Using hydrants | Frozen hydrants

Frost-free yard hydrants are installed to provide water to various locations in the farmyard during all seasons of the year. They are manufactured and installed in such a way that they will operate throughout the winter without auxiliary heat.

Operation

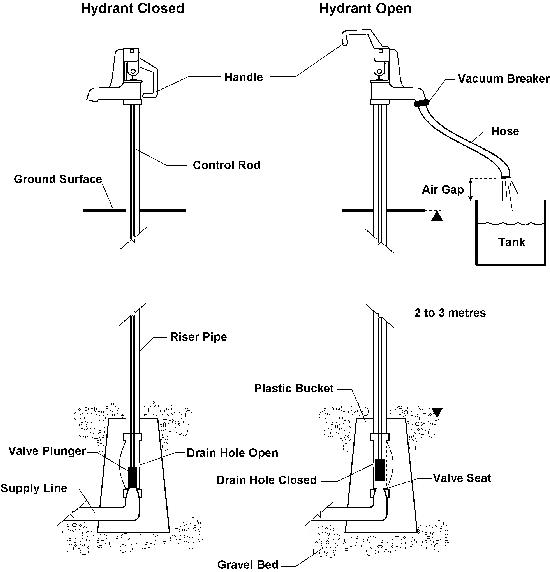

A major component of a hydrant is a stop-and-drain valve. This valve is located below frost level, usually 2 to 3 m below the ground surface. The valve is operated by a lever or wheel that is connected to the valve by a control rod. When the valve is open, water flows from the supply line, through the valve, up the riser pipe and out through the head of the hydrant.

When the valve is closed, the flow of water stops, and a drain hole in the valve opens. The water contained in the riser pipe flows out of this drain hole into a gravel bed, leaving the riser pipe empty and preventing ice formation.

Installation

It is important that the riser pipe drain quickly during cold weather to minimize the formation of ice inside the riser pipe. At least one cubic yard of clean, coarse gravel must be placed around the stop-and-drain valve of the hydrant. A container such as a heavy plastic bucket placed upside down around the valve will also aid the quick draining.

Any adjustment of the hydrant should be done before backfilling. Proper adjustment of the hydrant will allow:

- unrestricted flow when the valve is open

- no seepage past the valve when it is closed

- proper draining of the riser pipe when the valve is closed

- no leakage through the drain hole when the valve is open

A hydrant can be checked to see if it is draining by allowing the water to run, shutting off the hydrant and holding the palm of your hand over the end of the spout. If suction is felt, then the hydrant is draining.

The water pipe supplying the hydrant should never be less than 1 inch (25 mm) inside diameter. Hydrants should be located where they will not be subject to damage by livestock or machinery.

Hydrants should never be installed in or near wells or pump pits. Under the new water well regulations, it is illegal to locate a well inside a pit. Drainage from the hydrant can contaminate the well or flood a pump pit.

For example, the end of a hose being used to fill a sprayer tank may become submerged in the chemical solution. If the hydrant is shut off and starts to drain, a siphoning action will be started, and the chemical from the sprayer tank will be siphoned into the drainage area. If the hydrant drains into the well casing or well pit, the result may be considerable contamination.

An air gap must always be kept between a hose outlet and the highest possible water level in any tank. Anti-siphon or vacuum breaker valves are available for hydrants that will help prevent this very common type of accident.

Using Hydrants

If a hydrant is to be used frequently during summer months, it may be advantageous to put a hose bib or globe valve on the outlet of the hydrant. The hydrant valve can then be left open over the summer, and the gravel bed will remain dry to allow better winter drainage.

If a hydrant is used in winter, a large volume of water, 25 or 30 gallons (100 - 150 litres) should be drawn off occasionally. This action will melt the layers of ice that can build up in the riser pipe.

Hydrants make excellent risers for automatic stock waterers (see Agri-facts 716 (C52) Automatic Livestock Waterers). They allow individual waterers to be shut off in winter or during prolonged winter power failures.

Figure 1. Hydrant operation

Frozen Hydrants

A hydrant can freeze due to improper valve adjustment, a saturated drainage bed, a plugged drain hole or improper use, such as incomplete shut off or the constant withdrawal of only small amounts of water.

Should a hydrant freeze, it should be thawed as soon as possible to avoid damage. Hydrants frozen above ground level can usually be thawed by heating with an electric heat tape, a torch or hot water. If the hydrant is frozen below ground level, the head will have to be removed and hot water poured down the inside of the riser pipe. This step is most easily accomplished by soldering a copper tube to a funnel and pouring the hot water through the funnel and tube to the point where the ice has formed. The tube is pushed down the riser pipe as the ice melts.

For more information

Alberta Ag-Info Centre

Call toll-free: 310-FARM (3276)

Website: www.agriculture.alberta.ca

Prepared by

Alberta Agriculture and Forestry

Source: Agdex 716 (C51). Revised March 2008. |

|