| | Background | Mustard industry quality assurance | Mustard types and uses | Mustard production | Variety selection | Mustard cropping systems and rotations | Water and yield | Mustard benefits | Mustard establishment | Fertilizer requirements of mustard | Weed control | Disease management | Insect pests | Mustard harvest | Mustard drying and storage | Factors to optimize mustard production

Mustard is an important special crop grown on the Canadian prairies. It is well suited to production in the southern prairies including the Brown and Dark Brown soil zones.

Mustard has allowed producers in the drier regions to add an oilseed crop to their rotations, which has helped disrupt pest cycles, increase moisture use efficiency and increase farm income.

Mustard Factsheet Topics

- mustard types and uses

- production and variety selection

- cropping systems and rotations

- water use and yield

- benefits and establishment

- seeding and fertilizing

- weed control, disease management and insect pests

- harvesting, drying and storage

Background

Mustard is a significant special crop that has a farm gate value ranging from about 50 to 100 million dollars annually. In Canada, mustard production is focused primarily in the southern prairie regions of Alberta and Saskatchewan (Table 1), involving 370,000 to 740,000 acres (150,000 to 300,000 ha) and producing up to 300,000 tonnes of mustard seed annually.

Mustard is a relative of canola but tends to be more tolerant to drought, heat and frost. Canada produces three condiment mustard types: yellow (Sinapis alba), brown and oriental (Brassica juncea). Mustard is commonly grown in rotation with small grain crops.

Table 1. Mustard production in Canada from 1998 to 2008

| Year | Harvested area

(ha) | Average yield

(t/ha) | Production

(tonnes) | Farm cash receipts

(‘000 $) |

| 1998 | 279,000 | 0.85 | 239,000 | 87,716 |

| 1999 | 273,000 | 1.12 | 306,000 | 89,486 |

| 2000 | 208,000 | 0.97 | 202,000 | 63,763 |

| 2001 | 158,000 | 0.66 | 105,000 | 48,650 |

| 2002 | 255,000 | 0.61 | 154,000 | 59,089 |

| 2003 | 328,000 | 0.69 | 266,000 | 80,851 |

| 2004 | 304,000 | 1 | 306,000 | 82,021 |

| 2005 | 206,000 | 0.98 | 201,000 | 65,307 |

| 2006 | 130,000 | 0.84 | 108,000 | 48,690 |

| 2007 | 176,000 | 0.7 | 123,000 | 71,240 |

| 2008 | 186,000 | 0.87 | 161,000 | – |

| Mean | 227,500 | 0.845 | 197,300 | 69,681 |

(Source: Statistics Canada)

Canada is a world leader in condiment mustard seed marketing, accounting for 70 to 80 per cent of global exports, annually. The largest market for Canadian mustard seed is the United States, followed by Belgium, Germany, the Netherlands and Japan.

Mustard Industry Quality Assurance

Mustard quality in Canada is verified by the crop monitoring and quality assurance programs of the Canadian Grain Commission (CGC) and its Grain Research Laboratory.

Mustard contracting companies often use production contracts to ensure they can precisely meet buyer requirements. A number of mustard buyers now use identity preserved (IP) mustard production to guarantee that the supplier will deliver mustard with the exact qualities specified by the buyer.

Canada has established the Canadian Identity Preserved Recognition System (CIPRS), a third-party verification and certification service delivered by the CGC, to ensure that the production and supply chain meets specified requirements.

CIPRS certification guarantees that a contracting company has effective quality management systems for the production, handling and transportation of mustard, and that the product is fully documented and traceable from seed to domestic user or export vessel.

Mustard Types and Uses

Three types of condiment mustard are grown in western Canada, each with uniquely different end uses:

Yellow mustard (Sinapis alba) is primarily grown for the North American food processing and condiment industry. Yellow mustard is used as a binding agent and protein extender in prepared meats. It is also used for hot dog mustard, mayonnaise and salad dressings.

Brown mustard (Brassica juncea) is primarily grown for European markets for condiment specialty mustards such as Dijon mustard.

Oriental mustard (Brassica juncea) is primarily grown for the Japanese market and is primarily for condiment use. It is also used as spicy cooking oil in some Asian markets.

The Canadian Grain Commission “identifying classes of domestic mustard seed” types is shown in Table 2.

Table 2. Identifying classes of domestic mustard seed

| Class | Colour | Approximate size | Shape | Surface |

| Yellow | Light creamy yellow to yellow, occasional seed is light or yellowish brown | 2 to 3 mm in diameter | Spherical or oval | Textured, similar to an orange peel, hilum area –small white spot on a deep yellow to light tan circular area |

| Brown | Reddish brown to dark brown | 2 mm or less in diameter | Spherical or oval | Predominant netting, ridges are thicker than oriental mustard, hilum area – white on a black or darker brown circular area |

| Oriental | Predominantly yellow to dark yellow, with some seeds ranging from light brown to brown | 1.2 to 2.0 mm in width, 1.6 to 3.0 in length | Oval | Predominant netting, not as predominant as brown mustard, ridges are fine, hilum area – white on a darker yellow to lighter brown circular area |

| Mixed | Yellow and brown mustard seed containing less than 90.0% of one class

See also Domestic mustard seed, oriental: Other classes |

Mustard Production

Mustard is a broad-leaved, yellow-flowered, annual, cool-season crop that requires a relatively short growing season. Yellow mustard needs about 85 to 95 days and oriental and brown varieties need about 95 to 105 days to reach maturity, depending on seeding date and growing degree day (GDD) conditions.

Typically, yellow mustard needs about 1,520 to 1,625 GDD (0 °C base) to reach full maturity for direct harvest while brown and oriental mustards need about 1,440 to 1,540 and 1,510 to 1,610 GDD to reach swathing stage and full maturity, respectively.

Mustard seedlings are relatively more tolerant to late spring frosts than canola or flax. Mustard is generally considered to be more tolerant to drought and heat than canola and, therefore, is well suited to production in the drier Brown and Dark Brown soil zones.

However, the evidence is contradictory. In some experiments, B. juncea was found to be more drought tolerant than Argentine (B. napus) canola while other researchers report no difference.

Moisture and heat stress caused by hot, dry conditions during the flowering period in Brassica crops can adversely affect pollen and ovary viability resulting in fewer pods and fewer seeds per pod and, thus, lower seed yield.

The majority of mustard production in western Canada is under rain-fed conditions, but mustard is also responsive to irrigation. Mustard is typically grown in rotation with cereal crops.

The challenge for prairie mustard growers to optimize production is to utilize the newest varieties with a careful focus on agronomic practices including crop rotations, seeding dates, seeding rates, fertilizer management and pest management to ensure seed production will meet industry quality standards.

Variety Selection

Mustard growers must consider various factors when selecting the mustard type and variety to be grown. Selection of mustard type is often based on expected price, yield potential and the requirements of the contracting company.

Within each mustard type, there is not a lot of variation in disease tolerance, maturity or yield; however, growers should select the variety to be grown based on yield potential and the agronomic characteristics most suitable for their agro-ecological area.

For current information on mustard varieties refer to “Varieties of Grain Crops” on the Saskatchewan Agriculture website.

Mustard Cropping Systems and Rotations

To achieve optimum mustard yield and quality, the first important step is field selection based on previous crop and residue conditions. Using diverse crop rotations that include three or four different crops is generally the most desirable crop production practice. Crop rotations affect residue conditions in fields, soil moisture conditions and weed, insect and disease pressure.

Ideally, mustard should follow a cereal crop. A break of several years break between canola and other mustard types is needed to minimize volunteers that would contaminate the grain and thus lower the grade. Generally, mustard is not subject to the same insect or disease pressures as cereal crops.

Mustard should not follow pulse or oilseed crops. Under high potential yield conditions, mustard is susceptible to the disease sclerotinia (Sclerotinia sclerotiorum), which also affects most pulse crops such as pea or lentil and oilseed crops such as canola, flax or sunflower. Therefore, to minimize sclerotinia problems with mustard, growers should limit the frequency of susceptible crops in the crop rotation with mustard. However, sclerotinia is generally not a significant problem in most mustard dryland production areas.

Before the early 1990’s on the prairies, mustard was traditionally grown under conventional cultivation. In the drier regions of the prairies, wheat has been the most common cereal crop grown, and mustard generally grows well following wheat. Mustard was commonly grown on summerfallow in the drier regions, and in moister regions, it has been grown on stubble.

Prior to 1990, mustard was mostly grown using conventional tillage and seeding equipment. During the 1990’s, with the improvement of no-till seeding equipment, there has been a gradual shift from conventional cultivation and seeding to direct seeding mustard. In 1991, only 3 per cent of Alberta cropland was direct seeded; however by 2006, 47 per cent of all land inthe province was direct seeded. In Saskatchewan,60 per cent of all cropland was direct seeded in 2006.

The shift toward direct seeding has resulted in increased soil moisture conservation, which, in turn, has reduced the amount of land in summerfallow across the prairies. This approach has led to a shift in cropping systems used by prairie farmers.

The shift to direct seeding has created new weed control challenges and problems due to lack of herbicides registered for mustard. The use of herbicides that require incorporation tends to be less effective when these herbicides are only broadcast without incorporation.

More diverse crop rotations have been adopted that include annual crops (cereals, oilseed and pulse crops). This shift to more diverse crop rotations has created a sustainable environment to reduce disease problems and has also made it more difficult for weeds to adapt.

Water and Yield

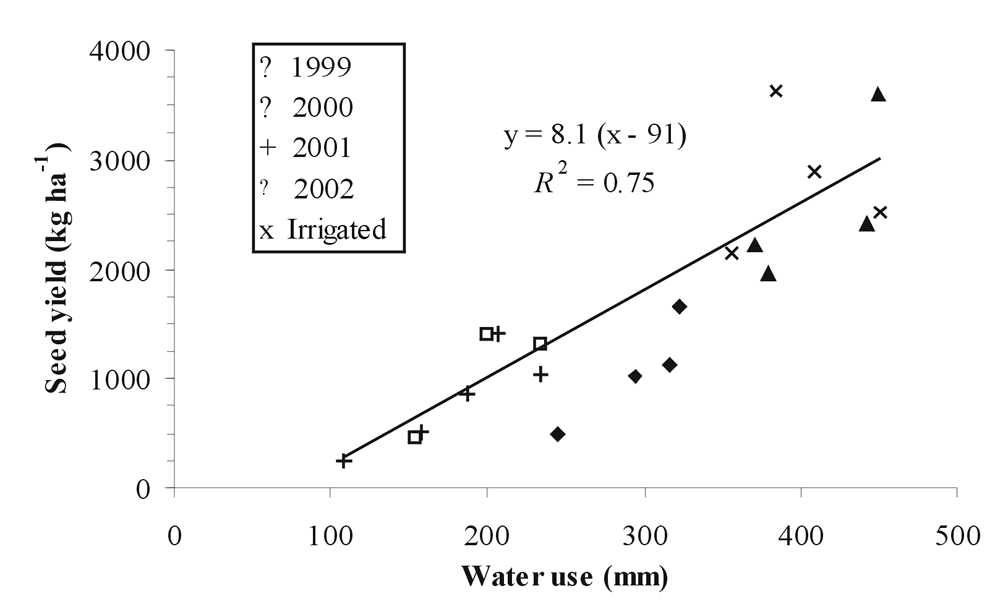

Mustard yields are greatly influenced by water availability. In a study with yellow mustard at 20 sites in southern Alberta (Brown and Dark Brown soil zones), the average water use efficiency (the amount of grain produced per inch [or mm] of water) at these sites was 182 lb/acre/inch (8.1 kg/ ha/mm) above a minimum of 3.6 inches (91 mm) of water. Mustard research in Saskatchewan found that the amount of water to establish seed yield was in the range of 4.8 to 6.3 inches (121 to 161 mm) versus the 3.6 inches in Alberta. Alberta sites were direct seeded, usually in late April, which likely increased water use efficiency. The water use efficiency was slightly higher in Alberta than values reported in Saskatchewan (6.9 to 7.6 kg/ha/mm).

Improved water use efficiency results in more grain produced per mm of water. The potential to increase mustard yield through increased water use efficiency occurs when greater amounts of soil moisture are conserved and greater amounts of precipitation are stored and greater yields are achieved by using good agronomic practices.

Higher water use efficiency in the Brown and Dark Brown soil zones can be attributed to improved cultivars and improved agronomic practices, including direct seeding, which conserves soil moisture. The relationship of grain yield to water use is linear (Figure 1). From Figure 1, grain yield steadily increases with increased water up to about 17.7 inches (450 mm) of water.

Figure 1. Relationship of mustard grain yield (AC Pennant Yellow Mustard, 120 kg N ha-1) to total water use (precipitation + soil water depletion to 0.9 m between planting and harvest) in south Alberta (McKenzie et al. 2006).

The relationship of mustard grain yield to water use is affected by potential evapotranspiration and the timing, duration and intensity of periods of water deficit. Farmers can optimize mustard yields by optimizing water use through good agronomic practices such as early seeding and using soil moisture conservation practices such as direct seeding.

Mustard Benefits

A benefit of including mustard in crop rotations is that soil organic matter levels and soil quality can be maintained or even improved by including mustard in the rotation. After grain harvest in direct seeded cropping systems, leaving mustard residue well spread on the soil surface helps protect the soil from wind and water erosion, reduces soil moisture evaporation losses and leaves weed seeds stranded on the soil surface.

A further benefit of including mustard in more diverse crop rotations is that the practice assists with the interruption of weed populations through inhibition of germination and some diseases such as take-all in wheat.

Mustard Establishment

Mustard has a very small seed and, therefore, must be seeded shallow at 0.6 to 1 inch (1.5 to 2.5 cm) into firm, moist soil. Direct seeding into standing stubble in early spring is ideal to achieve shallow seeding into moist soil. Standing stubble helps to reduce wind velocity and reduce moisture loss from the seedbed.

Successful direct seeding requires even distribution of crop residue the previous fall. Spreading residue the width of the swather or combine at harvest is critically important. Harrowing in the fall when the straw is dry will also help evenly distribute straw residue, but will have little effect on chaff distribution.

Uniform residue will help ensure uniform seedbed moisture and uniform emergence. Poorly spread residue can result in patchy mustard emergence as a result of variable soil moisture and soil temperatures in high versus low residue areas as well as greater emergence difficulties in heavy trash areas. Hard spring frosts can cause higher mortality to mustard seedlings in heavy residue areas compared to bare ground due to lower surface temperatures in the morning.

Seeding date

Mustard grown in Alberta is generally higher yielding when seeded in early spring. Early seeded mustard tends to have a yield advantage in the southern prairies because the crop can capitalize on early spring moisture, longer spring days, greater potential photosynthesis and often slightly cooler temperatures during flowering before the hottest part of the summer. Therefore, moisture use is optimized, and temperature stress is minimized, resulting in higher crop yields.

In a three-year Alberta Agriculture study at 20 research sites across southern Alberta, delayed seeding reduced seed yield, often substantially. Seed yields were reduced when seeding dates were delayed by as little as seven to ten days, although the yield penalty varied from year to year, depending on weather conditions.

In 2000, yield reductions due to delayed seeding were significant at all sites at the third seeding date, but were not significant at the second seeding date. In 2001, yield reductions were significant at both the second and third seeding dates at most sites. On average, yields were reduced 40 per cent at the third seeding date compared to the first seeding dates in 2000 and 2001. In 2002, yields at the third seeding date were reduced by 18 per cent at three sites, but were reduced by 64 per cent at a fourth site. Generally, research in southern Alberta and west central Saskatchewan has clearly shown that mustard should be seeded as early as is practical.

Row spacing

The highest yields of mustard are generally produced from rows spaced 6 to 10 inches (15 to 25 cm) apart. Most commercial seed drills used in western Canada have furrow openers spaced 6, 7 or 9 inches (15, 18 or 23 cm) apart. Weed growth tends to be more abundant in rows spaced more than 9 inches (23 cm) apart than in narrower rows.

When mustard is swathed, stubble to support the swath can be a problem as row width is increased. Seed openers that do not place the seed in rows, but scatter the seed in a 2, 3 or 4 inch (5, 7.5, or 10 cm) band usually have good yield potential and have the advantage that higher safe amounts of fertilizer can be seed-placed, provided there is adequate on-row packing.

Seeding depth and rate

As noted, mustard seed is small and must be planted shallow at a 0.6 to 1 inch (1.5 to 2.5 cm) depth into a firm, moist seedbed. When surface soil conditions are very dry, seeding depth could be increased to 2 inches (5 cm), but in normal years, this approach will reduce crop emergence and plant stand.

Yellow mustard seed is larger than the other types with approximately 100,000 seeds/lb (220,000 seeds/kg) and is normally seeded at a rate of approximately 8 to 10 lbs/acre(9 to 11 kg/ha). Brown and oriental mustards have approximately 200,000 seeds/lb (440,000 seeds/kg) and are normally seeded at a rate of 5 to 7 lbs/acre (5.5 to 8 kg/ha). Due to a larger seed size, yellow mustard has a slightly higher emergence percentage than the other types.

On average, mustard emergence is 50 to 80 per cent on the prairies in non-drought springs. Seeding at higher rates should be used with soils that tend to crust, land that has emergence concerns or on productive soils with a higher yield potential.

Ideally, seeding mustard at a higher rate results in a denser crop stand, which is more competitive with weeds and assists with cultural weed control. Higher seeding rates will increase plant population and, therefore, increase the potential to suppress and compete with weeds, and ultimately, increase potential yield.

Fertilizer Requirements of Mustard

Mustard requires careful attention to nutrient requirements to develop a sound, balanced fertilization program to achieve optimum yields.

Soil testing

Soil sampling and testing is necessary to determine soil nutrient levels that can then be used to determine the fertilizers required and the correct application rates.

Detailed information on soil sampling and testing is available on the Alberta Agriculture website.

Nitrogen

Nitrogen (N) is frequently the most limiting nutrient for mustard production. On continuously cropped land in western Canada, mustard responds strongly to the addition of N fertilizer, and yield gains in the range of30 to 60 per cent or more are common.

Alberta research has concluded that N fertilizer application was the most influential agronomic factor controlling the yield and quality of mustard in southern Alberta. Adequate N promotes vigorous plant growth, a large leaf area with a deep green colour, sufficient branching, flower and pod growth.

Mustard contains more N than any other essential elements derived from the soil. All mustard types are very sensitive to insufficient N and are very responsive to N fertilization when available soil N levels are low. Adequate N promotes vigorous growth and plays essential roles in plant proteins and chlorophyll.

Mustard takes up N from the time the roots begin to function until all uptake of nutrients and water ends with maturity; however, the majority of N is taken up by the flowering stage. Nitrogen uptake after flowering is contingent on sufficient soil moisture and, therefore, varies by agro-ecological area. Under normal growth conditions, the amount of N taken up is greatest during the early stages of growth, and then, N is translocated within the plant from leaves and stem to seeds during maturation.

Nitrogen in soil is primarily contained in the soil organic matter. Most of the organic N in soil is derived from plant proteins, and therefore, a significant amount of soil organic N is in the form of stabilized plant proteins or derivatives of proteins. A small portion of soil N is made up of inorganic N as exchangeable ammonium (NH4+) (attached to clay) and soil solution NH4+ and nitrate (NO3-).

The primary soil N source taken up by mustard roots is NO3-. To achieve optimum yield, an adequate supply of plant-available N is required. Soil N can come from various sources, but typically, the primary source is mineralization of soil organic N by microorganisms, which can contribute significant amounts of N to the plant-available N pool. The amount and rate of mineralization of soil organic matter is affected by soil temperature, moisture, pH, aeration, amount of soil organic matter and time of year.

Nitrogen in older leaves is redistributed to younger leaves to maintain growth. As a result, when N is deficient, the older leaves first show a characteristic lighter green to yellow colour; then, they will wither and drop by flowering.

The amount of nitrogen fertilizer required depends on four factors:

- level of soil nitrate-nitrogen (NO3-N)

- mineralization potential of the soil

- stored soil moisture

- expected precipitation

These conditions vary greatly. As the level of available soil nitrogen increases, the need for N fertilizer decreases, resulting in a lower response to N fertilizer. As stored soil moisture increases or growing season precipitation increases, the need for additional nitrogen fertilizer increases.

The optimum N fertilizer rate is a function of soil N, stored soil moisture (SSM) in spring and expected growing season precipitation (GSP). Therefore, soil testing for nitrate N to 24 inches (60 cm) and determining the amount of stored soil moisture before seeding are critical to aid in determining optimum fertilizer N rates.

In the Brown soil zone, if there is 2 inches (50 mm) of stored soil moisture and assuming that 6 inches (150 mm) of average growing season precipitation is received, the total amount of N needed by mustard would be approximately 60 lb N/ac (66 kg N/ha). Subtracting the amount of soil N from this figure will give the approximate rate of N fertilizer to apply.

Determining N requirement in the Brown soil zone:

With 2” of SSM + 6” of GSP then soil N + fertilizer N needed is approximately 60 lb/ac

With 4” of SSM + 6” of GSP then soil N + fertilizer N needed is approximately 75 lb/ac

With 6” of SSM + 6” of GSP then soil N + fertilizer N needed is approximately 90 lb/ac

Determining N requirement in the Dark Brown soil zone:

With 2” of SSM + 8” of GSP then soil N + fertilizer N needed is approximately 70 lb/ac

With 4” of SSM + 8” of GSP then soil N + fertilizer N needed is approximately 85 lb/ac

With 6” of SSM + 8” of GSP then soil N + fertilizer N needed is approximately 100 lb/ac

Determining N requirement under irrigation: The total amount of N (soil N + fertilizer N) required to achieve optimum yield is approximately 180 lb N/ac (202 kg N/ha).

SSM = stored soil moisture

GSP = growing season precipitation

Research conducted in Alberta has been used to develop general fertilizer recommendation tables for various soil zones and soil moisture conditions (Table 3). From Table 3, the amount of nitrogen fertilizer required by mustard for optimum yield can be estimated. However, Table 3 only provides general recommendations and does not consider crop value and N fertilizer price.

Table 3. Recommended nitrogen fertilizer rate (lb N/ac) in Alberta at various soil test N (NO3-N)

levels in the 0 to 24 inch depth with medium soil moisture

Soil zone |

| Brown | Dark Brown | Irrigation |

Soil moisture level* |

| Soil nitrogen level | Low | Medium | High | Low | Medium | High |  |

| (0-24") | (lb N/ac) |

| 0 | 60 | 75 | 90 | 70 | 85 | 100 | 170 |

| 10 | 50 | 65 | 80 | 60 | 75 | 90 | 160 |

| 20 | 40 | 55 | 70 | 50 | 65 | 80 | 150 |

| 30 | 30 | 45 | 60 | 40 | 55 | 70 | 140 |

| 40 | 20 | 35 | 50 | 30 | 35 | 60 | 130 |

| 50 | 10 | 25 | 40 | 20 | 25 | 50 | 120 |

| 60 | 0 | 15 | 30 | 10 | 15 | 40 | 110 |

| 70 | 0 | 5 | 20 | 0 | 5 | 30 | 100 |

| 80 | 0 | 0 | 10 | 0 | 0 | 20 | 90 |

| 100 | 0 | 0 | 0 | 0 | 0 | 10 | 80 |

| 110 | 0 | 0 | 0 | 0 | 0 | 0 | 70 |

| 120 | 0 | 0 | 0 | 0 | 0 | 0 | 60 |

| 130 | 0 | 0 | 0 | 0 | 0 | 0 | 50 |

| 140 | 0 | 0 | 0 | 0 | 0 | 0 | 40 |

| 150 | 0 | 0 | 0 | 0 | 0 | 0 | 30 |

*Soil moisture level: Low – 2 inches of stored soil moisture, Medium – 4 inches of stored soil moisture, High – 6 inches of stored soil moisture

Application time and placement of nitrogen fertilizer

Ideally, N fertilizer should be applied at the time of seeding, using a direct seeding system. As mustard is extremely sensitive to seed-placed N fertilizer, all N should be side-banded or mid-row banded at the time of seeding.

Direct seeded mustard should have most of the fertilizer side-banded with at least 1 inch (2.5 cm) of separation between the seed row and fertilizer band at the time of seeding. At a 10 per cent seedbed utilization, if morethan 10 lb N/ac (11 kg N/ha) of fertilizer is seed-placed, the seedbed utilization (SBU) must be increased. SBUis the width of spread of seed and fertilizer divided bythe row spacing times 100. For example, a 3” seed/fertilizer spread with a 9” row spacing has a SBUof 3/9 x 100 = 33%.

It is important to note that increasing the seedbed utilization will permit increased rates of seed-placed N; however, any germinating seeds that are immediately adjacent to urea granules likely will not survive.

Table 4 provides information to determine the amount of urea N fertilizer that can be safely seed-placed. These recommendations are for good soil moisture conditions (75 per cent of field capacity), which is when a loam to clay loam soil is wet, forms a ball and will ribbon between thumb and forefinger.

Table 4. Safe rates of seed-placed urea nitrogen for mustard in pounds per acre (lb/ac) when soil moisture

is good (75% of field capacity)

Seed and fertilizer spread (inches)1 |

| 1 | 2 | 3 |

Row spacing (inches) |

| 6 | 9 | 12 | 6 | 9 | 12 | 6 | 9 | 12 |

Seedbed utilization (SBU)2 |

| Soil texture | 17% | 11% | 8% | 33% | 22% | 17% | 50% | 33% | 25% |

| Light | 10 | 5 | 0 | 20 | 15 | 10 | 30 | 20 | 15 |

| Medium | 15 | 10 | 5 | 30 | 20 | 15 | 40 | 30 | 20 |

| Heavy | 20 | 15 | 10 | 40 | 30 | 20 | 50 | 40 | 30 |

1 Width of spread varies with airflow, soil type, moisture level, amount of residue and other soil conditions, and you should verify it in field.

2 SBU is the amount of the seedbed over which fertilizer has been spread. It is the width of spread, divided by the row spacing, multiplied by 100.

Source: Saskatchewan Agriculture and Food

If N fertilizer placement away from the seed is not possible, N fertilizer should be banded prior to seeding. The disadvantage of spring banding N fertilizer is that the seedbed will be compromised by the disturbance, and valuable soil moisture will be lost. Therefore, it is generally better to band N fertilizer in late fall.

For detailed information on fertilizing in the fall, refer to Alberta Agriculture’s Agdex 542-11, Fall-applied Nitrogen: Risks and Benefits.

In summary, when direct seeding mustard into soil with medium to fine texture and good soil moisture, it is recommended that the rate of N, using urea fertilizer, should not exceed 10, 30 or 50 lb N/ac (11, 33 or56 kg N/ha) with a seedbed utilization (SBU) of 10, 33 or 50 per cent, respectively, due to the potential toxicity of ammonia to germinating seedlings.

For farmers who want to place N fertilizer with the seed using a single shoot, direct seeding system, another option is to use coated, slow release urea such as ESNŽ (Environmentally Smart Nitrogen). This polymer coated urea will release the coated urea fertilizer slowly over a period of 20 to 40 days. Recent Alberta Agriculture research suggests that rates of up to 40 lb N/ac(45 kg N/ha) can be safely seed-placed with a 10 per cent seedbed utilization.

Phosphorus

The majority of prairie soils are considered phosphorus (P) deficient. Soil P availability to plants can be assessed by soil sampling and testing to determine plant-available soil P.

Research in Alberta has shown that the modified Kelowna soil test method commonly used by soil testing laboratories is the best method to predict P fertilizer requirements. Crop response to applied P fertilizer depends on the quantity of plant-available P already in the soil as well as soil moisture and temperature conditions.

It is also important to note that P levels in some soils have increased over the years as a result of repeated annual P fertilization. As a result, crops grown on some soils are less responsive to fertilizer P application. Additionally, factors such as rate of P fertilizer applied and the method of application can all affect plant uptake and response to P fertilizer. When environmental soil conditions are cool and wet, mustard tends to be more responsive to P fertilizer versus when soil conditions are dry.

Mustard is frequently most responsive to seed-placed P, followed by side-banded or banded phosphate fertilizer. Placing P fertilizers in bands minimizes the contact between the soil and the P fertilizer. In contrast, mixing the P with soil exposes it to more soil, resulting inreduced plant availability. Alberta research suggests that placement of P with the seed is frequently better than banded P, and both methods are superior tobroadcast-incorporation of P fertilizer.

For example, Table 5 compares canola response to seed-placed versus banded phosphate fertilizer in southern Alberta on summerfallow and stubble. Mustard data is not available; however, canola is physiologically similar, and P responses would likely be similar. Seed-placed P is recommended as it is an efficient means of P application, provided the amounts applied do not injure the germinating seed and seedlings. When higher rates of P are used in dry and/or coarse-textured soils, banding away from the seed at planting at times may be superior to placing phosphate with the seed.

Table 5. Yield response to seed-placed versus banded phosphate fertilizer in an Alberta canola study

| Canola |

Fallow | Stubble |

| Number of sites | 7 | 15 |

| P responsive sites | 6 | 14 |

| Seed-placed P > banded P | 5 | 6 |

| Banded P > seed-placed P | 0 | 2 |

| 1Seed-placed P = banded P | 1 | 7 |

(McKenzie and Middleton 1997)

A soil phosphorus calibration and response study with mustard was conducted in Alberta from 1999 to 2002, and Table 6 provides general phosphate fertilizer recommendations used in Alberta for mustard. When soil test P levels are medium to high and significant P fertilizer has been applied in the past 10 to 20 years, an annual maintenance application of phosphate fertilizer can be used to meet crop requirements and replenish soil P that is removed.

Table 6. Phosphorus fertilizer recommendations for mustard at various soil test levels using Kelowna or modified Kelowna method soil P

Soil

phosphorus | Soil zones |

Brown | Dark Brown | Irrigation |

| (0-6”) | (lb P2O5/ac) |

| 0-10 | 35 | 40 | 50 |

| 10-20 | 30 | 35 | 45 |

| 20-30 | 20 | 30 | 40 |

| 30-40 | 15 | 25 | 35 |

| 40-50 | 15 | 20 | 35 |

| 50-60 | 15 | 15 | 30 |

| 60-70 | 15 | 15 | 25 |

| 70-80 | 0 | 0 | 20 |

| 80-90 | 0 | 0 | 15 |

| >90 | 0 | 0 | 0 |

All soil P calibrations in Alberta are based on a 0 to 6 inch (0-15 cm) depth.

For greatest efficiency, phosphate fertilizer should be seed-placed with mustard. From a seed safety standpoint, not more that 15 to 20 lb P2O5/ac (17 to 22 kg P2O5/ha) should be seed-placed. Higher amounts should be side-banded away from the seed. To obtain best P fertilizer efficiency, adequate rates of nitrogen and other nutrients must also be available to the crop.

For more detailed information on phosphorus, refer to Alberta Agriculture’s factsheet Phosphorus Fertilizer Application in Crop Production, Agdex 542-3.

Potassium

Mustard takes up nearly as much potassium (K) as nitrogen and, therefore, has a high potassium requirement. Only 20 per cent of the K taken up is contained in the seed, while the remaining K in the leaves and stems is normally returned to the soil. The majority of western Canadian prairie soils have extractable soil K levels in the range of 400 to over 800 lb/ac(450 to 900 kgha) in the top 0 to 6 inches (0 to 15 cm).

Generally, mustard does not respond to K fertilizer when soil test levels are greater than 250 lb K/ac (280 kg K/ha) in the 0 to 6 inch (0 to 15 cm) depths. On fields that test less than 250 lb K/ac or on sandy soils or intensively cropped fields, K fertilizer may be required.

General potassium fertilizer recommendations for mustard on Alberta soils are summarized in Table 7.

Table 7. Potassium fertilizer recommendations for mustard using an ammonium acetate extraction

Soil

potassium | Soil zones |

Brown | Dark Brown | Irrigation |

| (0-6”) | (lb K20/ac) |

| 0-50 | 90 | 100 | 120 |

| 50-100 | 80 | 90 | 100 |

| 100-150 | 70 | 80 | 90 |

| 150-175 | 50 | 60 | 70 |

| 175-200 | 40 | 50 | 60 |

| 200-225 | 30 | 40 | 50 |

| 225-250 | 20 | 30 | 40 |

| 250-275 | 10 | 20 | 30 |

| 275-300 | 0 | 0 | 20 |

| >300 | 0 | 0 | 0 |

All soil K calibrations in Alberta are based on a 0 to 6 inch (0-15 cm) depth.

Potassium fertilizers are more efficient when seed-placed or banded. However, even small amounts of seed-placed potassium with mustard may reduce germination and emergence. Therefore, if potassium is required, banding or side-banding is the best placement method.

For more detailed information on potassium, refer to Alberta Agriculture’s factsheet Potassium Fertilizer Application in Crop Production, Agdex 542-9.

Sulphur

Mustard has a moderate requirement for sulphur (S). Mustard requires a constant supply of available S throughout the growing season with a higher requirement at flowering, as it is a major constituent of seed protein.

A 22 bu/ac (1,000 kg/ha) mustard crop (seed and straw) contains approximately 8 to 10 lb/ac (9 to 11 kg/ha) of sulphur, of which 40 per cent is in the seed. Sulphur deficiency is uncommon in the Brown, Dark Brown and irrigated soils of southern Alberta.

Soils deficient in S could have reduced seed yield without visual symptoms. The general recommendation for mustard production is 5 to 10 lb/ac (6 to 11 kg/ha) actual S as ammonium sulphate in the Brown and Dark Brown soil zones when soils are low in S.

In a four-year Alberta Agriculture study, the application of 10 lb SO4-S/ac (11 kg SO4-S/ha) did not increase yield at any of the 20 research sites, even though 12 of the 20 sites had less than 10 lb SO4-S/ac (11 kg S/ha) available in the 0 to 6 inch (0 to 15 cm) depth. However, almost all sites had significant SO4-S levels in the 6 to 12 and 12 to 24 inch (15 to 30 and 30 to 60 cm) depths.

The above research results illustrate the dilemma for southern Alberta dryland farmers: when surface soil S levels are low, should SO4-S fertilizer be added to prevent sulphur deficiencies in mustard?

Under irrigated conditions, there is normally sufficient SO4-S in the soil. Generally, there is adequate SO4-S in the irrigation water to meet crop requirements. For example, in 12 inches (30 cm) of typical irrigation water in southern Alberta, there is about 30 lb/ac (33 kg/ha) of sulphate sulphur.

Fertilizers, such as ammonium sulphate (21-0-0-24), that contain sulphate are most commonly used to correct S deficiencies. In fields that do test low or medium for SO4-S, a preventative or maintenance application of sulphate fertilizer at a rate of 5 to 10 lb S/ac (6 to 11 kg S/ha) could be considered to ensure adequateSO4-S will be available to the crop.

Mustard is sensitive to the salt effect of seed-placed ammonium sulphate. When there is adequate soil moisture, do not place more than 5 to 10 lbs S/ac (6 to11 kg S/ha) with the seed. If higher S rates are required, either side-band or use a higher seedbed utilization (sweep openers or spreader).

Broadcast or broadcast-incorporated application of ammonium sulphate can be satisfactory under adequate moisture conditions and can even be used for in-crop application at early growth stages to correct an S deficiency. However, when dry soil conditions occur, even the soluble sulphate fertilizer can become stranded above the actively absorbing roots. Therefore, seed-placed or side-banded sulphate is normally superior.

For more detailed information on sulphur, refer to Alberta Agriculture’s factsheet Sulphur Fertilizer Application in Crop Production, Agdex 542-10.

Micronutrients

No micronutrient deficiencies have been identified in southern Alberta with mustard. For more detailed information on micronutrients, refer to Alberta Agriculture’s Micronutrient Requirements of Crops, Agdex 531-1.

Weed Control

Weeds can greatly reduce mustard yields by competition for available light, nutrients and moisture. Although mustard seedlings are not very competitive with weeds, growers can minimize the early effects of weeds by several methods:

- Using a burndown of weeds in fall and/or early spring.

- Direct seeding as early as possible into a clean field to establish mustard as quickly as possible in the spring.

- Seeding at an optimum rate with high quality seed to maximize competition and suppression of weeds.

- Seeding as shallow as possible to encourage rapid, uniform emergence.

- Spraying as early as possible after crop establishment to remove weeds as quickly as possible to minimize weed competition.

Unfortunately, there are no registered herbicides available for in-crop control of a number of weeds including annual sow thistle, Canada thistle, common groundsel, dandelion, field bindweed, narrow leaved hawk’s beard, perennial sow thistle, shepherd’s purse, stork’s bill and Tartary buckwheat. Mustard should not be grown on fields with significant amounts of weeds that cannot be controlled chemically.

Ideally, the control of perennial weeds such as Canada thistle or dandelion should occur in the previous crop year. In the fall, products such as glyphosate can be used while weeds are still actively growing. Spring treatment to control perennial weeds before planting is usually not practical, but a spring burndown of winter annuals and annuals in fields that will be direct seeded is important for optimizing weed control.

A number of herbicides are registered for weed control in mustard. After identifying the weeds in a mustard field, growers can use the most recent issue of Crop Protection, Alberta Agriculture’s publication Agdex 606-1, for the selection of appropriate herbicides.

For in-crop control, it is important to note that the herbicide ethalfluralin (e.g. Edge) is only registered for use with yellow mustard and that ethametsulfuron methyl (e.g. Muster) is only registered for use with brown and oriental mustard.

Weed seeds, which are difficult to remove from mustard seed, can cause high losses during seed cleaning and will lower market grades. For example, cow cockle, cleavers, wild mustard, wild buckwheat and volunteer canola are extremely difficult to remove from harvested mustard. Land used for mustard production should be free from these problem weeds. Ensuring optimum weed control in mustard is important to achieve the highest market grade, lowest dockage and highest net financial return.

MUSTARD GROWERS MUST ONLY USE REGISTERED CROP PROTECTION CHEMICALS.The use of unregistered products can result in serious legal repercussions.

Disease Management

The use of good cultural practices including tracking disease occurrence, using proper crop rotations and the use of seed treatments is important in disease management in mustard. Weeds in the crucifer family can serve as hosts or sources of mustard diseases and, therefore, must be kept in control.

Seedling diseases such as damping off or root rot are caused by soil-borne fungi. Diseases such as alternaria black spot are caused by seed and soil-borne fungi. To minimize potential seedling disease problems, seed early and no deeper than 1 inch (2.5 cm) to assist with rapid germination and emergence. To minimize seedling diseases, use a registered seed treatment.

As mentioned in the Mustard Cropping Systems section, canola, safflower, flax, pea, lentil, chickpea and dry bean should not be grown one to two years before mustard in a crop rotation, as they have common disease problems, specifically sclerotinia.

If mustard follows crops susceptible to the same diseases, yield losses from disease can increase to economic threshold levels. Therefore, mustard should not be grown more frequently than every fourth year, on land that has been in an oilseed or other disease-susceptible crop.

Mustard is susceptible to a number of diseases, the most potentially serious being sclerotinia stem rot. Sclerotinia is a soil-borne fungus that infects plants at flowering from air-borne spores. The incidence of this disease varies from year to year, but it is more prevalent in years with wetter than normal conditions.

Fungicide application can provide effective control when the crop is at 10 to 50 per cent bloom, before symptoms are visible. Application is only economical when there is a high level of infection risk.

The risk for sclerotinia can be assessed by monitoring environmental conditions up to the time of flowering. Warm, dry weather during flowering will minimize risk while damp weather will increase disease risk. Good cultural and agronomic practices are the best measures for disease control.

Some other mustard diseases that are potentially of concern include the following:

White rust/staghead is a fungal disease where spores cause deformed and swollen flowering stems and pods. The swollen spiny stagheads are initially green and turn brown to white. Most yellow mustard varieties have good resistance to staghead, and recent brown and oriental varieties have improved resistance.

Alternaria black spot is a fungal disease that causes floret abortion, premature ripening, and pod splitting. Normally, this disease is very low in severity except in wet, cool late summers.

White leaf spot/grey stem is a fungal disease where white spots appear on leaves usually at the rosette stage, and as the disease advances, grey specked patches appear on stems and pods giving the whole plant a grey appearance. Although the disease occurs across the prairies, it normally does not affect mustard yield.

Clubroot is a destructive soil-borne disease that causes club-shaped root galls on the roots of mustard. It is a problem with canola in central Alberta but to date, has not been reported on mustard in the prairie provinces.

Ideally, to minimize disease problems in mustard, it is best to grow this crop in a rotation with small grains. Growing mustard only once every four years in a crop rotation is the best way to avoid problems with soil or crop residue-borne diseases.

Insect Pests

Growers should monitor fields closely to detect insect problems that can result in yield losses. The more common insect pests of mustard include flea beetle, cutworm, grasshopper, diamond back moth, armyworm and cabbage seedpod weevil.

Yellow mustard is immune to the cabbage seedpod weevil and has some tolerance to flea beetles; oriental and brown mustards, like canola, are more susceptible to insect pests than yellow mustard.

At germination and emergence, mustard should be closely monitored for cutworm feeding. If significant feeding damage occurs, insecticide application may be necessary, but difficult to implement for these subterranean pests.

At the seedling stage, heavy feeding of adult flea beetles can cause serious damage particularly to the Brassica mustards. Damaged plants may die or suffer reduction in vigour, particularly in hot, dry conditions. Hot weather can result in heavier feeding, while cool or wet conditions will slow flea beetle feeding. Injured plants may wilt and die during hot, dry weather, which can result in mild to severe yield losses.

Serious crop damage does not usually occur once the crop develops beyond the seedling stage since vigorous plants can outgrow beetle damage. It is suggested that the use of a registered seed treatment that contains an insecticide to control flea beetles on seedling mustard is a wise practice for oriental and brown mustard. If seedling damage by flea beetles exceeds 50 per cent at the cotyledon stage, then a foliar insecticide should be applied.

As the crop enters the early flower stage, growers should monitor oriental and brown mustard for cabbage seedpod weevils; yellow mustard is not susceptible and does not need monitoring for this pest. A nominal economic threshold of four weevils per sweep at the early flower stage can be used to make a control decision.

Towards the end of flowering and early pod formation, diamond back moth feeding on mustard can be serious. Control is recommended when numbers exceed an economic threshold of 30 larvae/sq ft. Similarly, Bertha armyworms will feed on mustard and control may be necessary when numbers exceed the economic threshold of three larvae/sq ft.

For detailed information on registered seed treatments and in-crop insecticides available for mustard, refer to the most recent issue of Alberta Agriculture’s publication Crop Protection, Agdex 606-1.

Mustard Harvest

Yellow mustard is resistant to shattering, so it can often be straight cut. It should be threshed when the moisture content is less than 9.5 per cent. If yellow mustard is to be swathed, then at least 75 per cent of the seeds should have turned yellow and the remaining 25 per cent should be firm and pale green. Mustard does not ripen in the swath like canola; therefore, care is needed not to swath too soon, or the amount of green seed will be excessive.

Brown and oriental mustard will change colour more in the swath than yellow mustard. Both types can be swathed when the moisture content of the grain has dropped to less than 25 per cent. In the case of oriental mustard, usually 75 per cent of the seed will have turned yellow, and with brown mustard, at least 60 per cent of the seeds should be brownish or red.

When swathing mustard, the use of a swath roller to compact the swath will minimize the amount of loss from wind damage. In windier regions, cutting the mustard a little higher and then pushing the swath into the stubble may minimize wind damage and loss. However, this approach must be balanced against the increased difficulty in picking up a shorter swath that is anchored into stubble.

Mustard is easily cracked when it is threshed. Therefore, combine cylinder speed should be reduced to as low as possible, in the range of 400 to 800 RPM. Tolerance for cracked mustard seed is very low. For Grades 1 and 2, the tolerance for cracked seed is less than 1.5 per cent.

Desiccation

Desiccation is not commonly used for mustard. Reglone is presently the only registered desiccant for mustard. Desiccation will result in accelerated plant drydown, but will not hasten maturity. Mustard should not be desiccated until 75 per cent of the seeds have turned colour.

Desiccation will terminate the green growth of pods and stems and will also kill weeds present in the field. This approach will allow mustard to be straight combined when the seeds are fully mature and have undergone complete colour change. Generally, desiccation usually takes about 7 to 14 days to be complete, depending on weather conditions.

For complete, detailed information on desiccation timing and rates, refer to the registered product label recommendations.

Mustard Drying and Storage

Mustard seed should be stored at a moisture content of9 per cent and at a temperature of less than 20 °C.

When mustard is initially put into storage, seed still has a relatively high respiration rate, which can result in moist areas within the storage bin. These areas are subject to heating; therefore, the temperature should be monitored in stored mustard to watch for heating problems.

If mustard has a moisture content of between 9.5 and15 per cent, then drying is necessary for safe, long-term seed storage. Normally, drying temperature should not exceed 43 °C, and seed damage will occur at 49 °C.

When seed moisture content is greater than 15 per cent, drying is recommended in two stages to avoid seed damage. Mustard should be dried down to 13 per cent moisture and then allowed to cool to outside air temperature, then followed by drying again down to9 per cent moisture content and allowed to cool.

For more detailed information on the drying and storage of seed, excellent information is available on the Canola Council of Canada website.

There are no primary insect pests of concern with stored mustard seed. Mites and sometimes psocids (often called dust lice, but not true lice) can cause an issue with stored mustard. Usually, large mite or psocid populations result due to heating or condensation development within the storage bin. Mites (not technically insects) are not a big concern on their own, but they are an indicator that mustard storage conditions are not favorable, and a management strategy for the storage conditions is necessary.

An important issue related to storage is the unregistered use of products such as malathion to treat grain bins used to store mustard. This insecticide use practice is presently acceptable for cereals but is not registered for mustard and, therefore, must not be used.

Factors to Optimize Mustard Production

In striving to achieve higher mustard yield and quality, growers must focus on nutritional and agronomic management at a high level. Improved management techniques should include the following:

- Improved use of crop rotations to minimize the negative effects of diseases and some insects.

- Shift to direct seeding mustard to improve management of soil moisture and allow for shallow seeding (less than 2.5 cm) into a moist seedbed. Direct seeding will also improve soil conservation, reduce wind and water erosion, increase soil organic matter and tilth as well as minimize incorporation of weed seeds into soil. All these factors will aid in increased mustard yield and quality.

- Using appropriate seeding practices, including optimum seeding rates and dates, to achieve optimum yield and crop quality.

- Rapid adoption and use of new mustard cultivars and the use of high quality seed.

- Development and use of seed treatments to minimize the effect of seedling diseases and insect pests.

- Soil sampling fields yearly to evaluate soil nutrient status to develop optimum nutrient management plans.

- Side-band or mid-row band N fertilizer at the time of seeding at optimum rates to target optimum production and seed placement of safe rates of phosphate fertilizer.

- Use of herbicides applied early to optimize weed control and minimize effects of weed competition on mustard.

- Only use registered crop protection products.

References

Angadi, S.V., McConkey, B.G., Cutforth, H.W., Miller, P.R., Ulrich, D., Selles, F., Volkmar, K.M., Entz, M.H. and Brandt, S.A. 2008. Adaptation of alternate pulse and oilseed crops to the semiarid Canadian Prairie: seed yield and water use efficiency. Can. J. Plant Sci. 88:425-438.

Bailey, K.L., B.D. Gossen, R.K. Gugel and Morrall, R.A.A. (Editors). 2003. Diseases of field crops in Canada. Publisher Canadian Phytopathological Society. 290 pages.

Brandt, S.A. 1992. Depths, rates and dates of seeding and yield of yellow mustard (Sinapis alba L) in west-central Saskatchewan. Can. J. Plant Sci. 72:351-359.

Gan, Y., Angadi, S.V., Cutforth, H., Potts, D., Angadi, V.V. and McDonald, C.L. 2004. Canola and mustard response to short periods of temperature and water stress at different developmental stages. Can. J. Plant Sci. 84:697-704.

Gan, Y., Malhi, S.S., Brandt, S., Katepa-Mupondwa, F. and Kutcher, H.R. 2007. Brassica juncea canola in the Northern Great Plains: Responses to Diverse Environments and Nitrogen Fertilization. Agron. J. 99:1208-1218.

Johnston, A. M., Tanaka, D. L., Miller, P. R., Brandt, S. A., Nielsen, D. C., Lafond, G. P. and Riveland, N. R. 2002. Oilseed crops for semiarid cropping systems in the northern Great Plains. Agron. J. 94: 231-240.

McKenzie, R.H. 2000. Potassium fertilizer application in crop production. Alberta Agriculture and Food. Agdex 542-9.

McKenzie, R.H. and Middleton, A.B. 1997. Phosphorus fertilizer application in crop production. Alberta Agriculture and Food. Agdex 542-3.

McKenzie, R.H., Middleton, A.B. and Bremer, E. 2006. Optimum fertilization, seeding date, and seeding rate for mustard in southern Alberta. Can. J. Plant Sci. 86:353-362.

McKenzie, R.H., Kryzanowski, L., Middleton, A.B., Solberg, E., Coy, G., Heaney, D., Harapiak, J. and Bremer, E. 2003. Relationship of extractable soil phosphorus using five different methods to the fertilizer response of barley, wheat and canola. Can. J. Soil Sci. 83:431-441.

Miller. P.W., Angadi, S.V., Androsoff, G.L., McConkey, B.G., McDonald, C.L., Brandt, S.A., Cutforth, H.W., Entz, M.H. and Volkmar, K.M. 2003. Comparing Brassica oilseed crop productivity under contrasting N fertility regimes in the semiarid northern Great Plains. Can. J. Plant Sci. 83:489-497.

Miller, P., Lanier, W. and Brandt, S. 2001. Using growing degree days to predict plant growth stages. Montana State University Publication MT200103 AG 7/2001.

Other information sources on mustard production

Manitoba Agriculture, Food and Rural Initiatives website

Saskatchewan Agriculture website:

Information prepared by

Dr. Ross H. McKenzie P.Ag.

Research Scientist - Agronomy

Agriculture Research Division

Alberta Agriculture and Rural Development

5401 - 1 Ave South

Lethbridge, Alberta T1J 4V6

Phone: 403-381-5842Fax: 403-381-5765

E-mail: ross.mckenzie@gov.ab.ca

Insect information prepared by

Dr. Hector Carcamo

Research Scientist – Entomology

Agriculture and Agri-Food Canada

Lethbridge, ABPhone: 403-317-2247

E-mail: CarcamoH@AGR.GC.CA

For more information

Alberta Ag-Info Centre

Call toll-free 310-FARM (3276)

Source: Agdex 143/20-1. January 2010. |

|