| | Why should manure be analysed? | Why is proper sampling important? | Sampling strategies for planning manure applications | Sampling solid manure, compost or litter | Sampling manure, compost or litter during application | In-barn sampling of poultry litter |Sampling poultry litter through a partially slatted floor | Sampling from stockpiled manure, compost or litter | Handling and shipping samples | Recommended analyses for manure samples | Conversion information for manure test results

Poultry manure is an excellent source of nutrients for annual and perennial crop production. It is critical to know the nutrient content of the manure to determine an appropriate manure application rate to meet crop requirements, maximize yield and minimize environmental impact.

This factsheet will discuss the importance and benefits of sampling manure as well as the best practices for sampling.

Why Should Manure be Analysed?

The nutrient content of manure may be obtained through manure sampling and analysis or from “book values.” Manure nutrient composition varies widely among farms due to several factors:

- differences in animal species

- diet and feeding practices

- bedding practices

- type of manure (liquid or solid)

- management of storage

- seasonal and environmental conditions

Book values may be a good place to start when calculating initial manure application rates, but they may not reflect the real nutrient content of the manure from a particular farm. The best way to get a farm-specific estimate of manure nutrient content is through proper sampling and analysis.

Why is Proper Sampling Important?

Proper sampling and handling is the most important factor affecting the accuracy of manure analysis. Since a very small amount of material is sent to a laboratory for analysis, it is essential that the sample collected be representative of the average composition of the manure being applied.

The nutrient composition of manure can change with time so manure should be sampled as close to the time of application as possible. This is especially true for uncovered storages and piles since seasonal variations in temperature and precipitation can alter nutrient content through dilution, evaporation and volatilization.

The nutrient content of manure stored in-barn or in covered storages or pits will not vary as much since there is limited exposure to environmental influences. An elapsed time of a few weeks between sampling and application is likely not critical.

The nutrient content of manure piles will vary spatially as manure is piled and mixed with bedding, spilled feed and soil. The nutrient composition of poultry litter in the barn will differ due to the location of feeding and watering facilities. If this variability is not addressed, test results will not reflect the nutrient content of the manure.

Spatial variability can be addressed through proper sampling techniques and procedures. Samples should be collected in such a way as to represent the variability of the material in the manure, i.e. bedding material. Manure samples should be collected and thoroughly mixed before a representative composite sample is selected for analysis. This practice will ensure that the collected sample reflects the nutrient content of the manure. Alternatively, several (three or more) composite samples may be collected for analysis, each representing the different types of material in the storage or the barn.

It is important to sample and analyze the manure each time it is applied. Sampling at the time of application will account for changes in nutrient content due to either time or material variation. Knowing the advantages and disadvantages of collecting samples either before or during application can assist in identifying appropriate sampling strategies for an operation.

Table 1. Sampling strategy

|  | Sampling prior to spreading |  | Sampling during spreading |

| Timeliness of test results | þ | Manure test results can be used to calculate appropriate application rates. | x | The analysis from these samples is not available for application, so application rates must be calculated using previous test results or book values. The results from the analysis of these samples can be used to calculate future application rates. |

| Accuracy of analysis | x | Difficult to obtain a representative sample of the manure because of non-uniformity prior to handling and hauling. Tests may not be accurate or representative because the manure is not thoroughly mixed. | þ | Sample collected and subsequently analyzed should better reflect the manure being applied.

Sub-samples can be taken as the manure is being hauled out, resulting in a more representative sample and reducing variability. |

| Difficulty to collect | x | Difficult to get a representative sample. Large equipment may be required to get a representative sample from a manure storage facility. | þ | Sampling during application requires very little extra time. |

| Safety | x | Sampling manure structures, especially liquid lagoons or tanks, can be dangerous due to the risk of falling in or being overcome by dangerous gases (H2S and NH3). | þ | Sampling from application equipment reduces risk of falling in or being overcome by gases (H2S and NH3). |

Sampling Strategies for Planning Manure Applications

It is important to note when collecting manure samples during an application that manure test results will not be available to calculate application rates for that application. The analysis, however, can be used to determine whether adequate amounts of nutrients were applied and to determine supplemental manure or fertilizer needs and application rates. Producers can use a manure analysis from the previous year to calculate the current manure application rate and the current analysis to estimate the next application rate.

Three to five years of manure analysis should provide an operation with baseline manure nutrient content values that can be used to calculate manure application rates. The more reliable the estimate of manure nutrient content, the more reliable the calculation of manure application rates.

Manure should be re-sampled and analyzed if you have made changes in the following:

- poultry management system

- feeding program

- manure storage and handling system

As long as significant changes in the production system have not been made, the nutrient content of the manure within an operation should remain fairly consistent.

Sampling Solid Manure, Compost or Litter

It is best to consult with the manure testing lab before sampling to identify lab-specific requirements for the following:

- sample size

- packaging and shipping

- turn-around times

- analytical options

- costs

Some labs provide containers, labels and submission forms and may cover the shipping costs depending on the number of samples submitted.

Tip: Use only plastic buckets for collection and mixing of manure samples because galvanized steel containers can interfere with analysis results. Do not use glass containers for either sampling or shipping due to the risk of breakage and subsequent injury.

Obtaining a representative manure sample can be very difficult.

- collected samples should be representative of the manure pile or litter pack that is scheduled for field application and the material’s average moisture content

- when sampling the manure, visible variations in moisture should be taken into account

- the greater the variability of the material within the pile or litter pack, the greater the number of composite samples that may need to be collected and analyzed to best manage the nutrient variability of the manure

- The total number of samples recommended to be collected depends on the amount of manure to be applied:

- for volumes of manure of less than 1,000 tonnes or material of consistent composition, a single composite sample may be collected and analyzed to get a good estimate of nutrient content for the volume of manure being applied

- for volumes greater than 1,000 tonnes, a minimum of three composite samples should be collected and analyzed

If multiple samples are analyzed, keep track of where the manure samples were collected and where the corresponding manure was applied. This approach will allow for site-specific nutrient management decisions.

Sampling Manure, Compost or Litter During Application

Sampling during application is much easier and safer than sampling from a manure pile or storage facility. Samples should be collected from the beginning, middle and end of the application process. This method will help ensure the manure samples collected represent the manure being applied. Single samples can be taken from each applicator during loading or, alternatively, samples may be collected from groups of loads representing the beginning, middle and end of the process.

Equipment needed for collection:

- a 20 litre (5 gallon) plastic pail

- a wheelbarrow

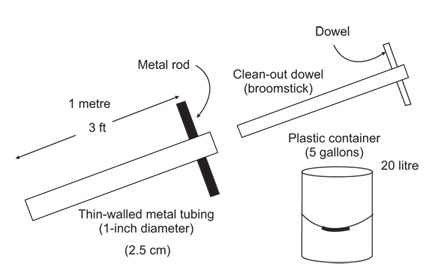

- a shovel, a pitchfork or solid manure-sampling probe (Figure 1)

- several tarps or a piece of plywood

- two or more large plastic re-sealable freezer bags

Collect samples using a wheelbarrow or pail. Depending on the amount of manure or litter being applied, the wheelbarrow or pail can fill up quickly.

Each time the wheelbarrow is two-thirds full, thoroughly mix the collected material, then remove one or two shovelfuls and transfer them to a tarp, piece of plywood or a concrete area that has been designated for mixing.

Samples should be stored in a cool location, such as a cooler with ice, until sampling is complete. Continue collecting samples until all the manure has been applied.

Recommended sub-sampling and packaging procedure:

Step 1 Combine all the manure samples from the pail or wheelbarrow on a tarp, piece of plywood or concrete pad and mix thoroughly. Large clumps should be broken up using a spade or fork.

Step 2 Divide the well mixed manure into four portions.

Step 3 Discard two of the four portions.

Step 4 Combine the remaining two portions and mix.

Step 5 Repeat steps 2, 3 and 4 until the remaining volume of material is small enough for analysis, approximately 0.5 kilogram (1 pound).

Step 6 The well mixed sub-sample should be placed in a plastic bag filled approximately one-half to two-thirds full.

Step 7 Squeeze the excess air out of the bag, close and seal. Samples should be double-bagged to prevent leaking.

Step 8 Label the bags with date, time, farm name and manure type.

Step 9 Bags should be kept cool and shipped directly to the lab for processing. If the samples cannot be transported on the day of collection, they should be frozen to stop nutrient conversion reactions until transport is possible.

Alternatively, manure can be collected during field application. To do this, place a minimum of three tarps, with more recommended for very large areas, across the field, so the tarps can catch the manure from several applicator passes. Collect samples from the entire application process. Although messy, this method of collection can provide a real estimate of the nitrogen applied after handling and application volatilization losses have occurred.

Thoroughly mix the manure collected on each tarp. Collect several small sub-samples from each tarp, avoiding larger pieces or chunks of bedding. Combine all the samples collected from each tarp and follow the recommended sub-sampling procedures previously described to collect a composite sample for analysis.

In-Barn Sampling of Poultry Litter

The consistency, make-up and nutrient content of dry litter vary across the width of the production house. Material from under the feeders and waterers will be different from the material along the walls and between the brood and grow-out areas. These differences must be considered when attempting to collect a representative manure sample from the litter pack in the production house.

There are two suggested methods for in-barn sampling of poultry litter, referred to as the “point” and the “trench” sampling methods.

Equipment needed for collection in either method:

- a 20 litre (5 gallon) plastic pail

- a wheelbarrow

- a narrow, square-ended spade or solid manure-sampling probe (Figure 1)

- a tarp or piece of plywood

- two or more large plastic re-sealable freezer bags

Figure 1. Solid manure-sampling probe

Point sample method

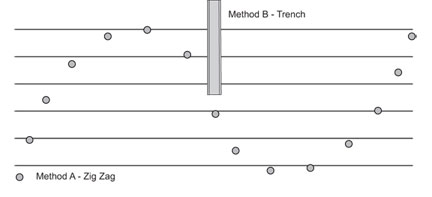

In this collection method, the entire house is sampled in a zigzag pattern (Figure 2).

Initially, assess the appearance of the litter pack in the house. If the manure in certain areas differs in appearance from others, collect a proportionate number of samples that reflect the size and number of these areas. If the area of difference represents 10 per cent of the barn, then 10 per cent of the samples should be from this area.

Figure 2. Poultry litter samples using trench and zigzag methods

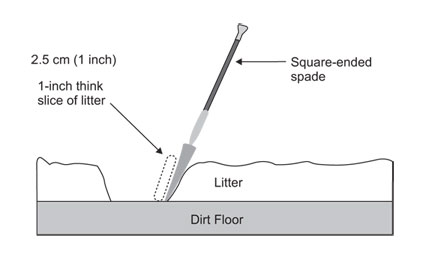

Next, randomly collect 15 to 20 samples with the spade or solid manure sampling device from the litter pack down to the depth the litter is to be removed. To collect the samples, clear a small trench the width of the spade and the depth of the litter. Take a 2.5 to 8 cm (1 to 3 inches) slice of equal amounts of litter the entire depth of the trench as a sample (Figure 3).

Be careful not to collect soil from beneath the litter as the soil will skew the nutrient content reported in the analysis. Take a representative number of samples near feeders and waterers that are proportionate to the space they occupy within the house. Place each sample in a plastic pail or wheelbarrow.

Figure 3. Sub-sampling using the point method

Once all samples are collected, use the procedure described previously to thoroughly mix and collect a sub-sample for analysis.

Trench sample method

In this collection method, dig a trench starting at the centre line of the barn, the width of the shovel, to the sidewall of the barn (Figure 2). The sampling trench should run perpendicular to the feed and water lines so as to collect a representative sample. The trench should extend through the litter to just above the earthen floor. Be careful not to collect soil from beneath the litter as it will skew the nutrient content reported in the analysis. If there is cake present, cut a shovel width of cake and collect it too.

Place all the litter collected from the trench into the wheelbarrow. Each time the wheelbarrow is two-thirds full, thoroughly mix the collected material, then remove one or two shovelfuls and transfer them to a pail or a place that has been designated for mixing. Empty the remaining litter from the wheelbarrow. Continue collecting and sub-sampling the litter until the trench reaches the outer wall.

Once the composite sample is collected, use the recommended procedure described previously for mixing and sub-sampling the material.

Sampling Poultry Litter Through a Partially Slatted Floor

A composite sample of manure is collected by sampling from the slatted floor and litter areas. Randomly collect at least 15 to 20 samples to get a representative sample from the building. If two-thirds of the house is under slats and one-third is litter area, collect 14 cores from under the slats and seven samples from the litter area.

Samples may be collected through the floor slats using a manure sampling probe or a section of pipe. Collect the litter samples in a zigzag fashion as mentioned previously (Figure 2). Be careful not to collect soil in the sample as it will skew the nutrient analysis.

Take a representative number of samples near feeders and waterers that are proportionate to the space they occupy within the barn and place them in a plastic pail or wheelbarrow. Each time the wheelbarrow is two-thirds full, thoroughly mix the collected material, then remove one or two shovelfuls and transfer them to a pail or a place that has been designated for mixing.

Once all the samples are collected, use the procedure recommended previously for mixing and sub-sampling the material.

Sampling From Stockpiled Manure, Compost or Litter

Sampling directly from a manure stockpile is not recommended because it is difficult to collect a representative sample. Fewer samples may be needed for homogenous piles that are applied frequently. Multiple samples may be required to represent the variability of a large quantity of variable material.

Note: The weathered exterior of uncovered manure piles does not accurately represent the majority of the material in the pile and should be avoided during sampling. Rainfall generally leaches water-soluble nutrients into the pile, while nutrients subject to volatilization will generally gas-off.

Equipment needed for collection:

- a 20 litre (5 gallon) plastic pail

- a wheelbarrow

- a shovel, a pitchfork or solid manure-sampling probe (Figure 1)

- a tarp, a piece of plywood or a concrete mixing area

- two or more large plastic re-sealable freezer bags

Only the portion of the pile that is being applied needs to be sampled. Depending on the size, variability and age of the material in the pile, it is recommended that a minimum of three composite samples, each collected from 10 to 20 different locations on the pile, be sent for analysis to get a representative estimate of nutrient content.

A key factor in obtaining a good sample from a storage facility is to collect multiple samples from throughout the pile. Samples should not be collected from freshly piled or turned manure unless the manure is going to be applied within the next few days. The manure’s nutrient content should stabilize within about two weeks of creating or turning an existing pile. Samples should be collected when the nutrient content of the material is fairly stable.

Figure 4. Collecting manure from a stockpile

Photo courtesy of Ontario Ministry of Agriculture, Food and Rural Affairs

Collection procedure

The following procedure should be repeated for each composite sample collected.

Step 1 Select 10 to 20 widely dispersed sampling points on the pile.

- Select sites that represent the average moisture content of the material.

- Samples should be collected from the entire pile. Collect samples from near the edge of the pile to the center of the pile. It may be necessary to use a front-end loader to access the centre of the pile.

A sample can then be obtained from the bucket of the loader.

Step 2 Remove the top crust layer from each of the sample points.

Step 3 Collect samples using a pitchfork, spade or manure collection probe.

- Avoid sampling the weathered exterior layer (outer foot) of the pile.

- Samples should be collected to a depth of at least 45 centimetres (18 inches) into the pile.

Step 4 Collect three to five sub-samples from each sample point and place them into a wheelbarrow.

Step 5 Each time the wheelbarrow is two-thirds full, thoroughly mix the collected material, then remove one or two shovelfuls and add them to the pail or place on the tarp or concrete area you have designated for mixing.

- Collected samples should be stored in a cool location until sampling is complete.

Step 6 Continue collecting samples until all selected points have been sampled.

Step 7 Use the sub-sampling and packaging procedure recommended previously for collecting a composite sample for analysis.

Handling and Shipping Samples

Manure samples should be tightly sealed to prevent leakage and double-bagged as an extra precaution. To ensure that samples sent for analysis are representative of the original manure nutrient content, proper precautions must be taken to avoid leakage, nutrient loss by volatilization, moisture loss and nutrient transformations. The following approaches are recommended:

- Keep samples cool by refrigerating or by placing on ice until they are transported to the lab. Do not allow the samples to sit in a warm environment for longer than a few hours. Warm temperatures promote nutrient conversion that will change the nutrient content of the sample.

- Samples should be transported within a day. If this is not possible, they should be frozen until shipped.

- Samples should spend no more than two days in transit. Samples should be collected Monday to Wednesday so that shipping can be scheduled to ensure that they are not held over weekends or holidays.

- Clearly label all samples with a permanent marker. The label should include the the owner’s or operation name, contact information, date of collection and type of manure.

Recommended Analyses for Manure Samples

Laboratories offer a variety of tests and analysis packages. The following is a list of recommended analyses for all manure samples:

- moisture content or dry matter content

- total nitrogen (Total Kjeldahl Nitrogen TKN)

- ammonium nitrogen (NH4-N)

- total phosphorus (P)

- total potassium (K)

Optional tests could include total nitrate-nitrogen (NO3-N), electrical conductivity (EC), pH, total carbon or carbon/nitrogen (C:N) ratio, chloride (Cl), sulphur (S), sodium (Na), calcium (Ca), magnesium (Mg) and micronutrients such as copper (Cu), manganese (Mn), zinc (Zn) and iron (Fe).

It is usually not necessary to analyze manure for mineral constituents such as Ca, Mg, Zn and boron (B). Most manure contains significant quantities of these minerals, and fields with a history of manure application are rarely deficient.

Nutrient concentrations can be reported on an as-is basis in kg/tonne, lb/ton, kg/m3, kg/1,000 litres, lb/1,000 gallons or parts per million (ppm).

Conversion Information for Manure Test Results

P (Total phosphorus) x 2.29 = P2O5 (phosphate)

K (Total potassium) x 1.2 = K2O (potash)

per cent (%) x 20 = pounds per ton (solid manure)

per cent (%) x 10 = kilograms per tonne (solid manure)

mg/kg (milligrams per kilogram) x 0.002 = pound per ton (solid manure)

mg/kg (milligrams per kilogram) x 0.001 = kilograms per tonne (solid manure)

kilograms per 1,000 litres x 2 = pounds per ton (solid manure)

kilograms per tonne x 2 = pounds per ton (solid manure) 1 gallon (CAN) water = 10 pounds

1 gallon (US) water = 8.34 pounds

tonne x 1,000 = kilograms

mg/kg (milligrams per kilogram) = parts per million (ppm)

Summary

Poultry litter is an excellent source of nutrients for annual and perennial crop production. To determine an appropriate manure application rate to meet crop requirements, optimize crop yields and minimize environmental impact, it is essential to know the nutrient content of the manure being applied.

Samples should be collected in such a way as to represent the variability of the material in the manure. To obtain a sample that reflects the nutrient content of the manure, samples should be collected and thoroughly mixed before a representative composite sample is selected for analysis. For large quantities of manure or for material that is highly variable, several composite samples need to be collected and analyzed.

The best way to get an accurate, farm specific estimate of manure nutrient content is through proper sampling and analysis. The accuracy and reliability of a manure analysis is a direct reflection of the quality of the collected sample. The most convenient time to sample manure is when it is being hauled from the storage or barn for application. More importantly, a more representative sample can be collected as the manure is being loaded and hauled.

Two methods are suggested for in-barn sampling of litter, the ‘point’ and the ‘trench’ sampling methods. The nutrient content of dry litter varies across the width of the production barn. Material from under the feeders and the waterers will be different from the material along the walls and between the brood and grow-out areas. Collect a proportionate number of samples that reflect the size and number of these different areas.

Sampling from a stockpile of manure or from a storage facility is not recommended as it is difficult to collect a sample that is representative of the material in the pile.

It is best to consult with the manure testing lab before sampling to identify lab-specific requirements for sample size, packaging and shipping, turnaround times, analytical options, and costs.

Prepared by

Trevor Wallace – Nutrient Management Specialist

Stewardship Division

Alberta Agriculture and Forestry

Source: Agdex 538/450-1. August 2008. |

|