| | Galvanized pressure tanks | Precharged pressure tank | Sealed diaphragm pressure tanks | Tank sizing | Summary

A pressure tank is required in a farm water system to maintain pressure in the system when the pump is not in operation. The amount of water that can be taken from the system between pump cycles is called the "draw off."

Galvanized Pressure Tanks

The oldest type is the standard galvanized pressure tank. It relies on a cushion of compressed air to deliver the water to the distribution system while the pump is not operating.

Water under pressure has a high capacity for absorption of air and gases. In a standard galvanized pressure tank, the water and air are in direct contact, so the air is absorbed by the water over a time period of several months. The pressure tank becomes "water logged" when it contains insufficient air. In this situation, the pump will go on and off more often than necessary. In extreme cases the pump will go on and off every few seconds.

Some method of regulating the air volume in the pressure tank must be used. Air volume controls balance the air-water ratio in the tank by adding or releasing air, depending on the requirements of the pressure system. Too much air in the pressure tank can be caused by dissolved gases in the water or a piston pump that automatically adds air with each pump stroke. In this case, a "deep well automatic air control" is required. This control is float-operated and releases the excess air or gas.

Automatic air chargers perform the opposite function. They add air to the tank. Diaphragm-type controls add a small charge of air each time the pump stops, but only if air is needed. Both the above controls can be used with shallow or deep well jet pumps.

Precharged Pressure Tank

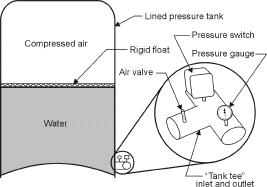

The next generation of pressure tank was the glass-lined pressure tank containing a rigid float (Figure 1). The rigid float covers the water surface and separates it from the air, thus slowing the rate of air absorption. Precharged with the recommended amount of air, these tanks will have up to double the "draw off" of a standard galvanized tank.

Figure 1. Precharged float-type pressure tank.

This type of tank must be recharged with air about once a year to prevent "water logging." To convert a standard galvanized pressure tank to a float-type tank, a rubber float can be rolled up and inserted through the 1¼ inch tapping.

Procedure for precharging pressure tanks and setting the tank discharge control valve:

- Shut off the pressure pump.

- Drain all water from the pressure tank, then add air to the pressure tank with an air compressor until air spurts out of the drain tap. Shut off the tap.

- Using a compressor, pressurize the tank to 3 to 5 psi below the pump cut-in pressure.

- Start the water pump.

Sealed Diaphragm Pressure Tanks

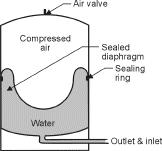

The latest type of precharged tank is made of fibreglass or metal and contains a sealed plastic or rubber air cell or diaphragm (Figure 2). This cell is precharged with air, leaves absolutely no air-water contact, and should never have to be recharged. If the tank needs to be recharged, it is likely because the diaphragm has ruptured and the tank needs to be replaced.

Figure 2. Sealed diaphragm.

Tank Sizing

Pressure tanks should be sized so that the pump will not cycle more than 25 times per hour. This set-up allows approximately 1 gallon of draw off for every 100 gal/hr pump capacity. For example, if a pump produces 600 gal/hr (10 gal/min), then the pressure tank should have a draw off of at least 6 gallons. The specification charts provided with the pressure tank will give the draw-off capacities at different pressures.

For normal farm use, a 42 gallon pressure tank is recommended as a minimum size. The larger the tank the better, especially if the well or pump has a low capacity. A relief valve should be installed if the pump is capable of generating more pressure than the maximum working pressure of the pressure tank.

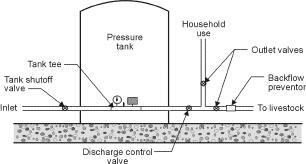

Figure 3. Pressure tank installation.

Summary

In most cases, a precharged bladder type of pressure tank is recommended because of the low maintenance requirements and the relatively high volume of draw off. Standard galvanized pressure tanks are a necessity in installations where air or other gases must be released from the pressure system.

For more information

Alberta Ag-Info Centre

Call toll-free: 310-FARM (3276)

Website: www.agriculture.alberta.ca

Prepared by

Alberta Agriculture and Rural Development

Source: Agdex FS716(C31). Revised April 2005. |

|