| | Purpose | Audience | Relevant legislation | Introduction | Concrete as a liner | Concrete categories and facility construction | Category A concrete liners | Category B, C, D concrete liners | Critical factors for concrete performance | Reporting and documentation | Category A concrete liners | Category B and C concrete liners | Category D concrete liners

Purpose

- Provide guidance for the design and construction of non-engineered concrete liners used for manure collection and storage areas

- Protect groundwater from contamination

Audience

- Operators, consultants, and contractors constructing concrete liners for manure collection and storage areas at confined feeding operations

Relevant legislation

- Agricultural Operation Practices Act and Standards and Administration Regulation

Introduction

Concrete is a practical, cost-effective and long-lasting material to use as a liner for manure collection and storage areas at confined feeding operations (CFOs). This technical guideline describes specifications for concrete liners that can be used to satisfy the requirements of the Agricultural Operation Practices Act (AOPA) and its regulations.

This guideline does not apply to manure collection and storage areas that use a natural protective layer, a compacted clay liner or a synthetic liner under the proposed concrete liner, provided that the layer or liner meets AOPA requirements.

Professionally engineered designs may differ from the specifications outlined in this guideline and may provide greater protection than AOPA requires.

This guideline also identifies when an operator must consult an engineer for a site specific design. If a site specific engineered design is not required, the operator has the option of having their concrete liner designed by an engineer.

Concrete liners must be constructed to ensure that groundwater is protected from manure constituents.

Concrete as a liner

Section 9 of AOPA’s Standards and Administration Regulation requires constructed concrete liners to provide equal or greater protection to groundwater resources than compacted soil. Section 9(6) sets out the thicknesses and hydraulic conductivity values of compacted soil that must be met or exceeded.

The concrete liner should be constructed to the minimum thickness required to maintain the structural integrity of the concrete liner and to prevent cracking and ensure durability.

Concrete categories and facility construction

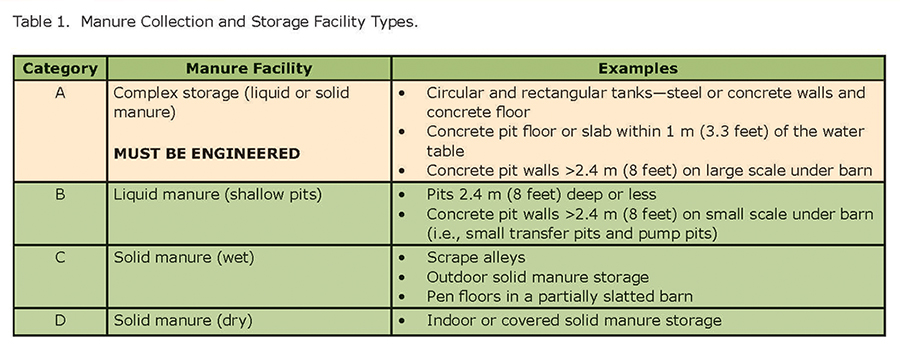

The concrete required for manure collection and storage areas is categorized by the complexity of the facility and the moisture content of the manure contained in the facility (see Table 1).

Category A concrete liners

Category A concrete liners are complex storage systems. A complex manure collection or storage area may contain liquid or solid manure. Examples include above ground liquid storage tanks, deep liquid pits and pit floors or slabs within one metre of the water table.

Category A concrete liners must be designed by a professional engineer and constructed under their supervision. An engineer must verify how the liner meets AOPA specifications.

To allow for maximum flexibility of engineering design, professional engineers are not required to follow the specifications outlined in Table 2.

Category B, C, D concrete liners

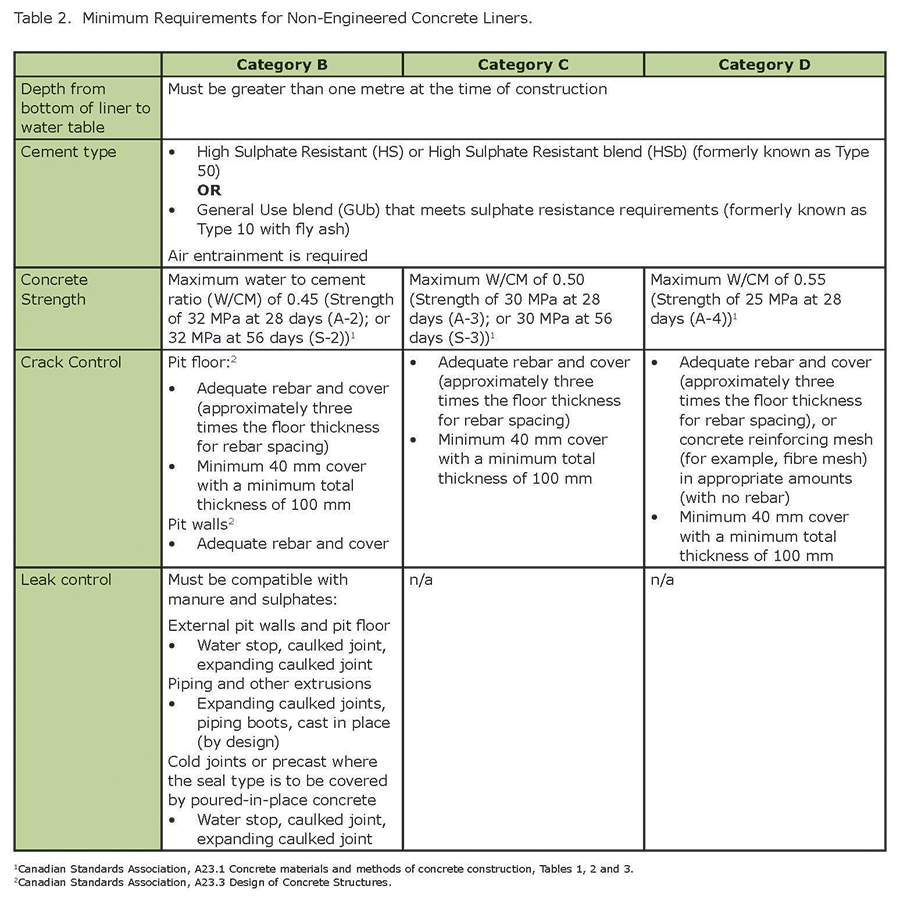

Category B, C and D liners are simpler manure storage systems used for lower risk sites that do not require a complex design.

The design and construction options for category B, C and D liners are

1) Engineered by a professional engineer,

or

2) If not engineered by a professional engineer, the design and construction must be in accordance with the specifications set out in Table 2.

.

Critical factors for concrete performance

Owners and operators are responsible for the following critical factors for concrete construction and maintenance:

- Design and construct each facility using high quality material (including low permeability concrete and proper aggregate),

with appropriate reinforcement and placement.

- Ensure water tightness and proper finishing. Water stops and control joints help prevent leakage.

- Properly place and cure the concrete, and protect it from extremes of cold and hot weather during the curing.

- Ensure the concrete meets the requirements for its intended use, for example, loader traffic.

- Monitor cracking, and repair cracks as soon as they occur.

|

Reporting and documentation

The Natural Resources Conservation Board (NRCB) typically requires reports and documentation for the four categories of concrete, as described below. NRCB approval officers have discretion to determine which reports and documents are required. However, approval officers may require more or less reporting and documentation for an individual permit condition, depending on the particular file.

Category A concrete liners

Approval officers may include a condition or conditions in the permit to require the applicant to provide an engineer’s completion report. As-built drawings from the engineer may also be required. The engineer may be required to report on the methods used to place and cure the concrete. In extreme cases, supervision could be required to ensure placement and curing is done according to the standards established by the Canadian Standards Association (CSA).

Category B and C concrete liners

To determine whether there are specific risks to groundwater associated with an application that will use a category B or C concrete liner, approval officers use the Environmental Risk Screening Tool (ERST) to determine the level of risk. The results determine which reports and documentation will be required.The approval officer may require the specifications listed in Table 2 and in the application to be proven to their satisfaction. For example, the approval officer may require ready-mix concrete delivery tickets or invoices, or evidence of water stops and rebar size, spacing and placement. For higher risk sites, the approval officer has discretion to require the contractor to provide this information in a completion report, and may also require as-built drawings. If self-mixed concrete is used, independent third party tests of the concrete quality may be required.

In addition, documentation may be required to confirm that the concrete meets sulphate resistance specifications or is equivalent to those specifications.

Category D concrete liners

Normally, minimal follow up is required. The approval officer may require the applicant to confirm that the concrete has been placed inside the facility. The approval officer also has discretion to require independent third party testing of the concrete quality if self mixed concrete is used. Tickets and invoices, evidence of rebar and completion reports are generally not required.

Documentation may be required to confirm that the concrete meets sulphate resistance specifications or is equivalent to those specifications.

For more information

Contact your nearest NRCB field office or an AF Agri-Environmental Extension Specialist (dial 310-0000 to be connected toll free)

Alberta Agriculture and Forestry

www.agriculture.alberta.ca/aopa

Ag Info Centre 310 FARM (3276)

Publications (780) 427-0391

Natural Resources Conservation Board

www.nrcb.ca

Fairview - closed, please contact Morinville.

Morinville (780) 939-1212

Red Deer (403) 340-5241

Lethbridge (403) 381-5166

This guideline was developed by the Technical Advisory Group, a partnership between Agriculture and Forestry, the Natural Resources Conservation Board and the agricultural industry.

Source: Agdex 096-93. June 2015. |

|