| | Contamination | Deterioration | Evaporation | Theft | Transportation

Storing fuel on the farm poses some interesting challenges to producers in order to maintain the quality and quantity of the product. Changes in quality or composition of the fuel due to contamination or deterioration can create a great deal of aggravation for farmers. Fuel losses can occur from leaks and spills as well as evaporation or theft. It is important to monitor for these losses so that the proper action can be taken in the event of such problems. For more information on monitoring for fuel losses, refer to the Appendix.

Contamination

Common fuel contaminants may include:

- Water

- Sediment, rust, etc.

The major contaminant of stored fuel is water. It can enter the system through leaks, condensation, from the fuel supplier or through vandalism.

Minimal amounts of water from condensation in underground and on-ground gasoline tanks can be dealt with by adding the appropriate fuel de-waterer. In diesel tanks, use a quality diesel fuel de-waterer. There are also water-absorbing fuel filters available in the market place but these filters need to be changed regularly as the water-absorbing polymers that trap the water will restrict fuel flow when it is time to replace the filter element. If a large amount of water exists, the only alternative may be to have the water pumped out. Determining how the water entered the system is also important in detecting possible leaks. In overhead tanks, water can be drained by removing the drain plug on the bottom of the tank. This is best done when the tank is almost empty. Catch the contaminated water for proper disposal.

Common sediments in the fuel tank are minute particles of rust caused by water contamination. Other sediments are formed when fuels stored for a long period begin to break down. Sediments can cause filter plugging, engine deposits, gumming and lacquering which lead to component sticking and engine wear. At the very least, contamination of fuel causes lost time and aggravation. Contamination of your engine’s fuel system can be minimized by not refueling within 24 hours of a fuel delivery. This will allow any small sediment particles to settle below the discharge height.

Overhead tanks should be checked annually for sediment. This is done by drawing off a litre of fuel from the fuel nozzle into a clear glass jar. If the sample is contaminated, ask your fuel supplier to co-operate by removing the entire contents and cleaning the tank. If the first sample is not contaminated, use a clean rod or stick to agitate the tank through the fill cap and draw off a second sample. If the second sample is contaminated, the tank should be cleaned at the first convenient opportunity.

Filters and sediment bowls on overhead tanks will minimize the chances of contaminating equipment fuel systems. The filter should have enough capacity to pass fuel at the usual rate of filling. The recommended size of filter is 10 microns. This size is sufficient for removing microscopic particles of rust, sand, dirt, scale and lint. Most fuel pumps are equipped with filter screens, which limit sediment contamination but require regular cleaning.

Figure 4: Fuel filter

Photo courtesy of Baldwin Filters

Other contamination occurs when fuel is delivered improperly or equipment is not properly fuelled. For example, gas mixed into diesel can cause extensive damage to diesel engines. Diesel fuel mixed into gas is generally not as serious a problem for gas engines.

Plastic tanks are not suitable for above ground fuel storage. Sunlight going through translucent tank walls promotes microbial growth and other fuel degradation. In addition, most plastic tanks are not strong enough for safe fuel storage.

Deterioration

Fuel deterioration is minimized when fuel is stored at a cool, constant temperature. The larger the temperature swings and the higher the temperature, the faster fuel will deteriorate. Degraded fuel results in poor engine performance, less power, harder starting and lower fuel economy.

Tips to prevent deterioration:

- Keep fuel at as cool and consistent a temperature as possible (for example, shade tanks from the sun)

- Limit fuel purchases to the volume required to seed and harvest one year’s crops (not only to reduce deterioration, but to reduce risk and cost of leakage, fire and theft)

- Purchase diesel fuel in the season in which it is being used (summer diesel may gel and cause engine problems if used at low temperatures)

In the event of a price war, there is always the temptation to purchase as much fuel as possible. Those with underground storage tanks are in the best position to take advantage of low prices. Underground tanks provide the best long-term storage capabilities. However, before purchasing fuel for long-term storage, carefully consider the risks, interest costs, tax implications and your ability to maintain the fuel in good condition.

Evaporation

Evaporative losses vary with the type of storage, type of fuel and steps taken to prevent evaporation. Losses range from minimal in underground tanks to easily measurable in poorly located and maintained overhead tanks. The greater the variations in temperature of the fuel, the greater the potential loss and the larger the risk of contamination due to condensation.

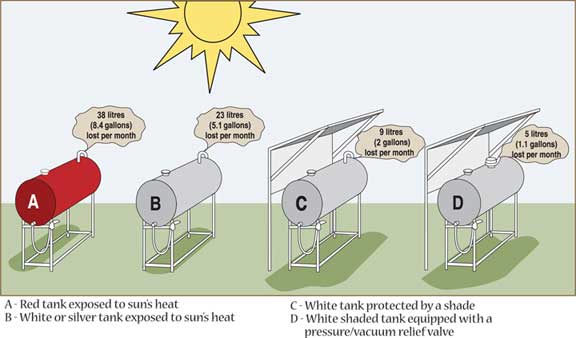

Table 1 and Figure 5 illustrate this variance in evaporative losses.

Table 1: Evaporative losses from 1,200 litres (265 gallons) above ground gasoline storage tanks

Referenced from University of Nebraska, 1981, and British Columbia Ministry of Agriculture and Lands, Farm Storage and Handling of Petroleum Product, June 2005

Figure 5: Summer evaporation losses from 1,200 litres (265 gallons) gasoline storage

Steps to reducing evaporation losses:

- By painting the tank a reflective paint (silver or white), evaporation losses can be reduced by up to 40% over a dark tank

- Using a pressure-ventilated cap can reduce evaporation losses a further 50% Direct venting of the tank fumes is restricted until a slight pressure has built up in the tank. Having a painted and pressure vented tank has a 75% evaporation loss reduction compared to a dark tank

- Placing a painted and pressure vented tank in the shade will further reduce the evaporation losses by over 40%. The roof also helps reduce weathering of hoses and valves

Resource Management Branch, BC Ministry of Agriculture and Lands

Evaporative losses are not a major concern in underground tanks and are only of minor concern in larger, on-ground tanks. The large volume of fuel and air helps to maintain a more even temperature. Owners should ensure that proper pressure-vacuum relief valves are installed on tanks. These valves will reduce evaporation while allowing vapours to escape before tank pressures become excessive.

Theft

Theft is a frustrating and difficult situation to deal with. Theft of fuel can vary from a nuisance factor to a substantial financial cost. Being an easy target for fuel theft can lead to further theft and vandalism on the farm, and larger losses. Keep track of fuel purchases and usage to know if there is an unexplained disappearance (see also Monitoring for Fuel Losses in the Appendix).

Tips for theft protection include:

- Locate tanks in a well lit area away from buildings and not visible from roads but still visible from your house

- Close and lock the valves on all on-ground and overhead tank outlets when not in use

- Lock fuel caps on underground tanks

- Turn off power to pumps (have switch in a locked building)

- Consider using hoses that are fitted with cam lock fittings and removed when not in use

- Some producers have used lockable nozzle racks as well as locking valves

Figure 6: Cam lock fitting

Transportation

According to the Transportation of Dangerous Goods (TDG) Regulation, the following precautions must be taken when transporting fuel tanks. No documentation or training is required when the following conditions are met:

Table 2. Summary of requirements for various sizes of portable tanks for gasoline and diesel

| Product | Tank Size | Requirements |

| Litres | Gallons |  |

| gasoline | 450 or less | 100 or less | UN #, shipping name and (Class 3) safety placard must be displayed |

| diesel | 450 or less | 100 or less | not regulated |

| gasoline | more than 450, but less than 2,000 | more than 100, but less than 440 | Class 3 safety placard must be displayed |

| diesel | more than 450, but less than 2,000 | more than 100, but less than 440 | Class 3 safety placard must be displayed |

The total capacity of all containers on the vehicle must not be more than 2,000 litres. For containers exceeding this capacity, full compliance is required. For further information, contact Alberta Transportation and Utilities.

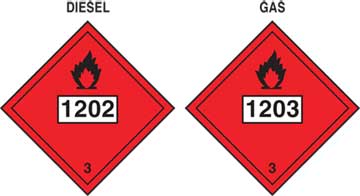

For example, for a portable tank containing gasoline, the UN number is “1203” and the shipping name is “gas” or “gasoline”. Also keep in mind your local fire authority may have regulations on parking in town with portable fuel tanks, and they vary by municipality. Parking of vehicles with slip tanks is not permitted in residential areas.

Figure 7: Placards showing flammable symbol, class, UN number and shipping name

Figure 8: Portable tank with proper signage, etc.

Photo courtesy of Westeel

It is recommended that both dangerous goods placards and WHMIS labels be used when transporting fuels.

Tip: When refueling from slip tanks, remember the dangers of static electricity. You can prevent this by grounding your tank (see section 7, Planning a Fuel Storage Site). Also, if your tank is equipped with a 12-volt pump, be careful to keep all electrical systems properly maintained to prevent sparks.

These labels and placards can be purchased through fuel suppliers or at safety supply stores.

The TDG Regulations do not apply to dangerous goods in a quantity less than or equal to 1,500 kg gross mass in transport on a licensed farm road vehicle if:

- The dangerous goods are transported on land for a distance less than or equal to 100 km,

- The dangerous goods will be used or have been used for agricultural purposes, and

- The dangerous goods do not include:

- Explosives

- Flammable gases in a cylinder with a capacity greater than 46 litres

- Toxic gases

- Infectious substances, or

- Radioactive materials.

Even though the transport of most fuel in “slip tanks” for farm use would be exempt from the TDG Regulation as described above, it also provides a reasonable set of guidelines for farmers to use in order to reduce their risk.

Source: Agdex 769-1. September 2008. |

|